Aluminate cement and preparation thereof

A technology of aluminate cement and a manufacturing method, which is applied in the field of cement materials, can solve the problems of not finding resources that can be effectively utilized and high production costs, and achieve the effects of pollution-free treatment and good industrialization prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

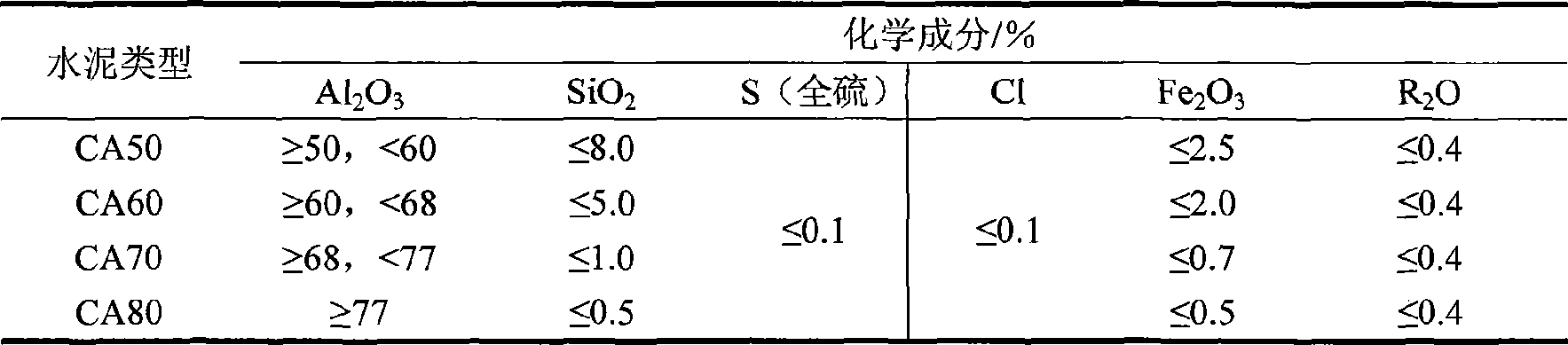

[0021] An aluminate cement and a preparation method thereof. Adopting the patented technology of "Preparation of Titanium and Titanium Alloys Using Titanium-Containing Slag" (ZL200510019664.3) patented by the applicant, the TiO 2 Titanium-containing blast furnace slag or titanium-containing slag produced by other smelting methods with a content of 10-90 wt%, plus 0-50% carbon, 0-40 wt% aluminum metal, 0-40% iron and 0-20% magnesium It is a reducing agent, and the amount of the reducing agent added is not zero at the same time. After mixing evenly, it is melted and thermally reduced to obtain titanium and titanium alloys.

[0022] Then use the residue after extracting titanium and titanium alloy by the patented method as raw material, add bauxite with 5% to 15% of the residue in the molten state, and obtain clinker by standing and cooling slowly after melting; then After crushing and grinding until the specific surface area is greater than 3000cm2 / g, aluminate cement is obtain...

Embodiment 2

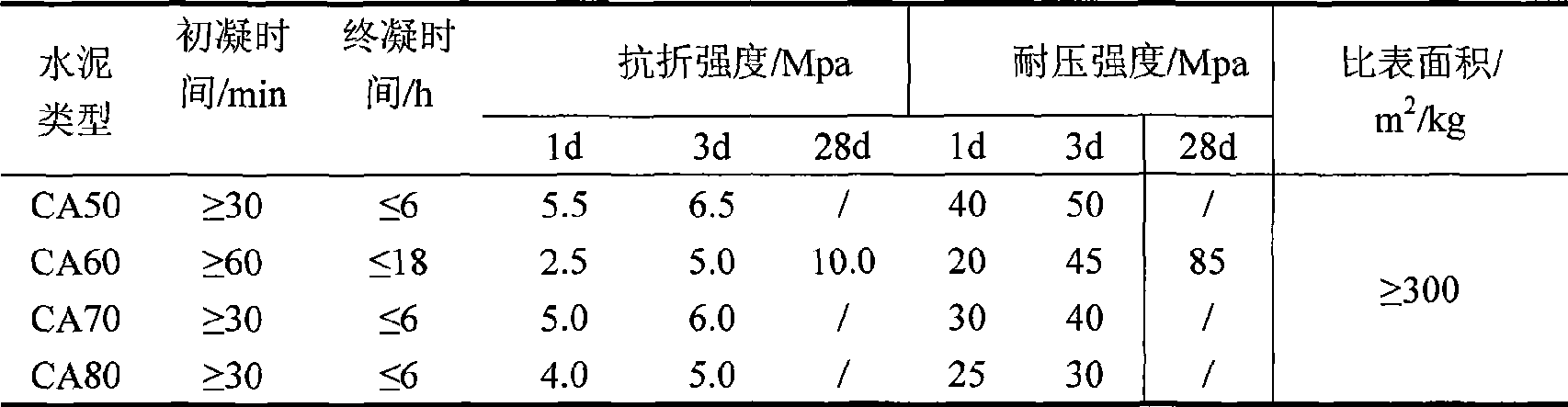

[0026] An aluminate cement and a preparation method thereof. The residue raw material adopted is the same as that in Example 1. The residue is in a molten state, and bauxite of 15% to 25% of the residue is added to adjust the composition. If the surface area is greater than 3000cm2 / g, aluminate cement can be obtained. Its chemical composition and physical properties are shown in Table 4.

[0027] Table 4

[0028]

Embodiment 3

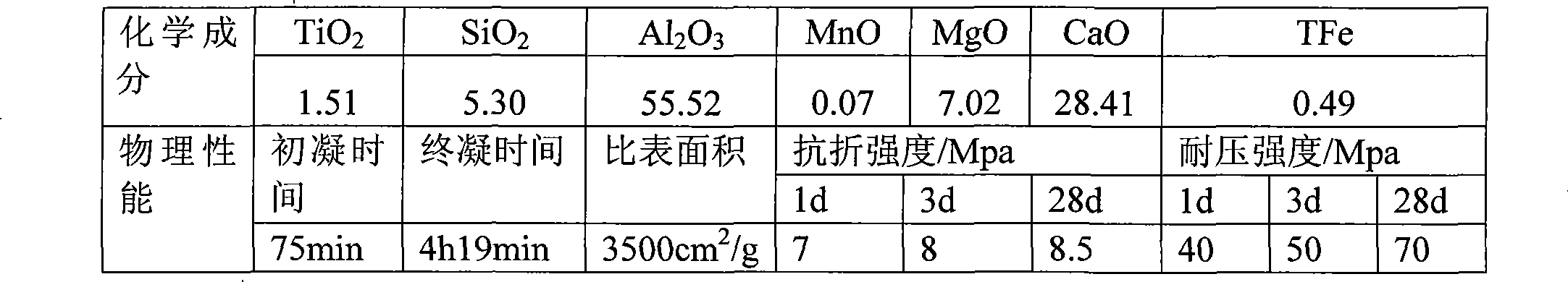

[0030] An aluminate cement and a preparation method thereof. The residue raw material used is the same as that in Example 1, the residue is in a molten state, bauxite with 25% to 32% of the residue is added, and the clinker is obtained by slow cooling after melting, and then crushed and ground until the specific surface area is greater than 3000cm 2 / g, the aluminate cement is obtained. Its chemical composition and physical properties are shown in Table 5.

[0031] table 5

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com