Process for manufacturing regenerative thermal-bonded spunbond nonwoven

A spunbond non-woven fabric and production process technology, applied in non-woven fabrics, textiles and papermaking, filament forming processing and other directions, can solve the problems of unfavorable energy saving, high manufacturing cost, achieve low shrinkage rate, reduce production The effect of enhancing breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

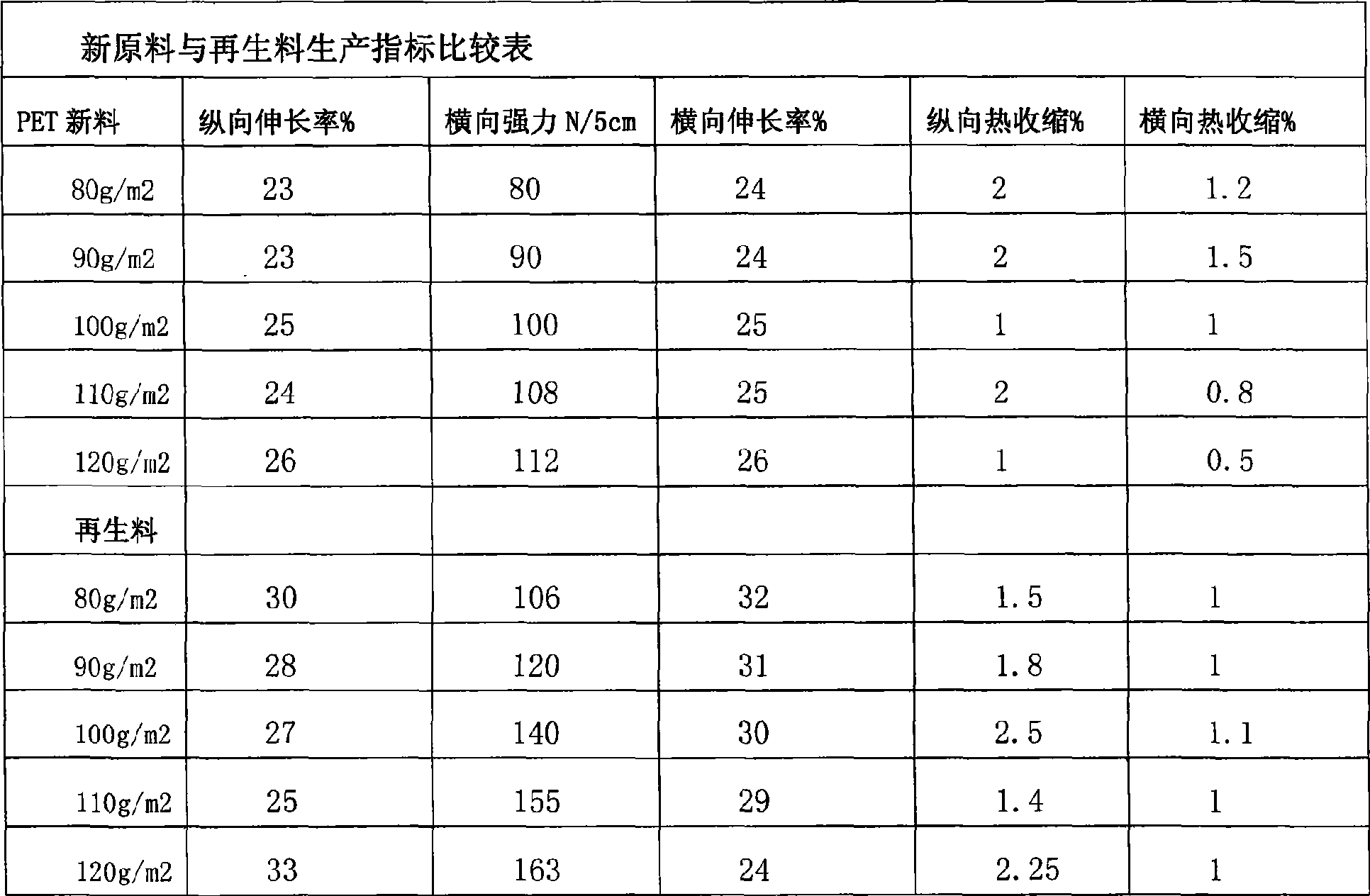

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments.

[0023] The non-woven fabric manufacturing process of the present invention utilizes recycled waste PET bottles as raw materials for processing and manufacturing. Therefore, the recycled PET bottles should be processed first. The treatment includes cleaning and sorting, crushing, high-temperature cooking, rinsing, drying and packaging.

[0024] The main purpose of cleaning and sorting is to remove impurities on the surface of the bottles, such as sediment, oil stains, etc., and to remove the labels of the labeled bottles; the sorting is mainly to remove the bottles made of PVC materials, and currently it is still mainly classified manually. In China, the sorting work has been basically completed at the waste recycling station, and more than 90% of the bottles that go to the cleaning plant are gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com