Method for producing iron runner ramming mass by recovering steel plant waste

A waste recycling, steel plant technology, applied in the direction of process efficiency improvement, discharge devices, etc., can solve the problems of large energy consumption, investment costs, pollution, environmental pollution, etc., to increase the number of jobs for employees, reduce environmental pollution sources, and good use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the formula of iron channel material

[0032] Component Weight Content

[0033] Aggregate 8-5mm 75kg 15%

[0034] 5-3mm 90kg 18%

[0035] 3-1mm 90kg 18%

[0036] 1-0mm 45 kg 9%

[0037] SiC90-98% 1-0mm 50kg 10%

[0038] Recycled waste powder 325 mesh 50kg 10%

[0039] Other finished powder 100kg 20%

[0040] The process is as follows: Weigh the recycled powder and other materials according to the content of the above formula, stir with rollers for 3-5 minutes, add 9% liquid resin, stir for 5-8 minutes, stir evenly for 10-12 minutes three times, and the finished product is packaged .

Embodiment 2

[0041] Embodiment 2: the prescription of iron channel material

[0042] Component Weight Content

[0043] Aggregate 8-5mm 85kg 17%

[0044] 5-3mm 100kg 20%

[0045] 3-1mm 100kg 20%

[0046] 1-0mm 40kg 8%

[0047] SiC90-98% 1-0mm 20kg 5%

[0048] Recycled waste powder 325 mesh 60kg 12%

[0049] Other finished powder 90kg 18%

[0050] The process is as follows: weigh the recycled powder and other materials in the above formula according to their content, stir with rollers for 3-5 minutes, add 7% liquid resin, stir for 5-8 minutes, stir evenly for 10-12 minutes three times, pack immediately for the finished product.

Embodiment 3

[0051] Embodiment 3: the prescription of iron channel material

[0052] Component Weight Content

[0053] Aggregate 8-5mm 65kg 13%

[0054] 5-3mm 100kg 20%

[0055] 3-1mm 100kg 20%

[0056] 1-0mm 35 kg 7%

[0057] SiC90-98% 1-0mm 50kg 10%

[0058] Recycled waste powder 325 mesh 50kg 10%

[0059] Other finished powder 100kg 20%

[0060] The process is as follows: weigh the recycled powder and other materials in the above formula according to their content, stir for 3-5 minutes with rollers, add 8% liquid resin, stir for 5-8 minutes, stir for 10-12 minutes three times, and pack immediately for the finished product.

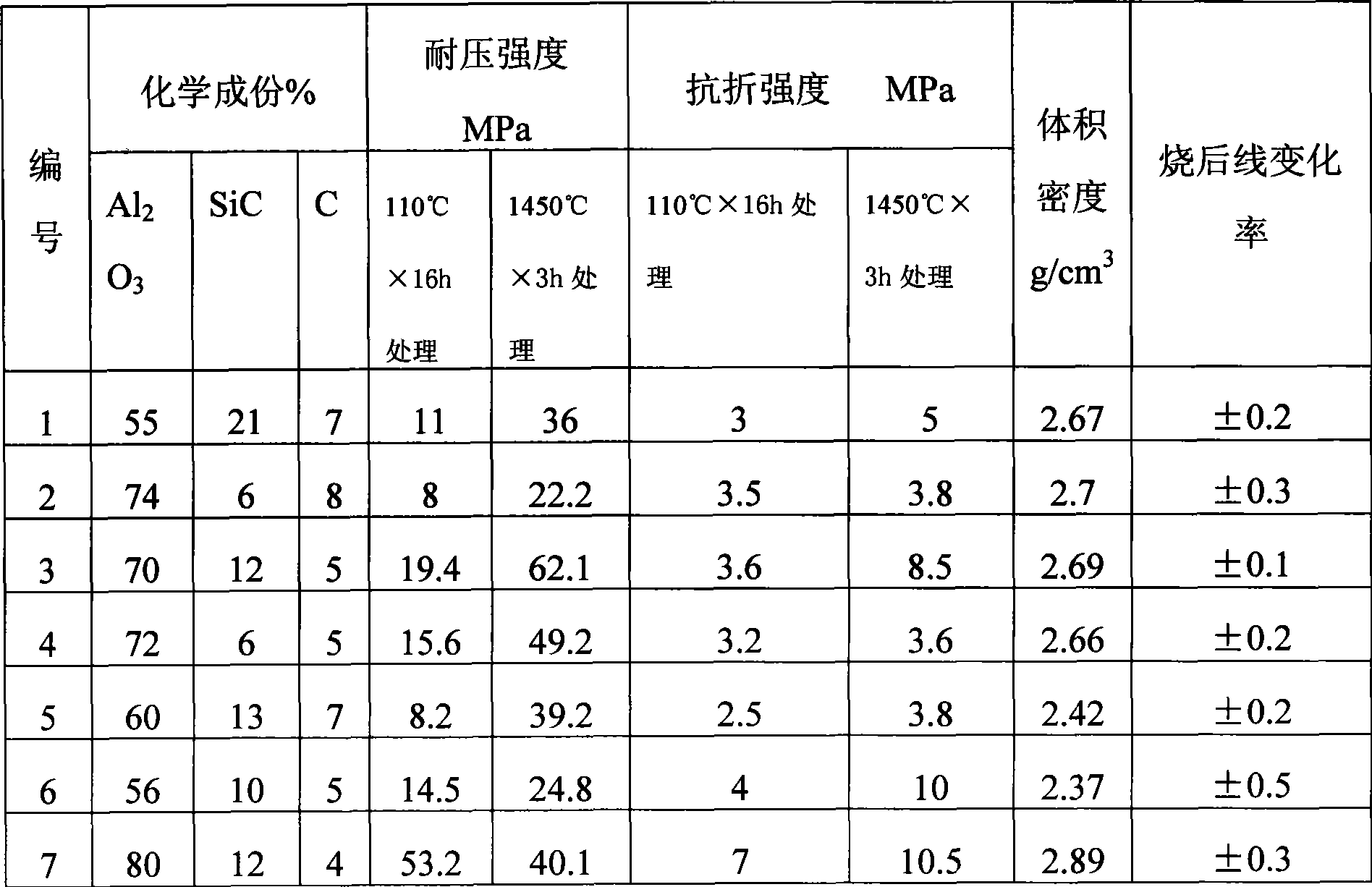

[0061] The main physical and chemical properties of the finished iron trench material

[0062]

[0063]The above performance finished products are used according to different user requirements and different use conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com