Method for preparing multilayer structure composite steel plate

A multi-layer structure and clad steel plate technology, applied in metal rolling, manufacturing tools, temperature control, etc., can solve problems such as difficulties, complex production processes, and difficulty in meeting high requirements for material properties, and achieve increased bonding strength and finer Organizational, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

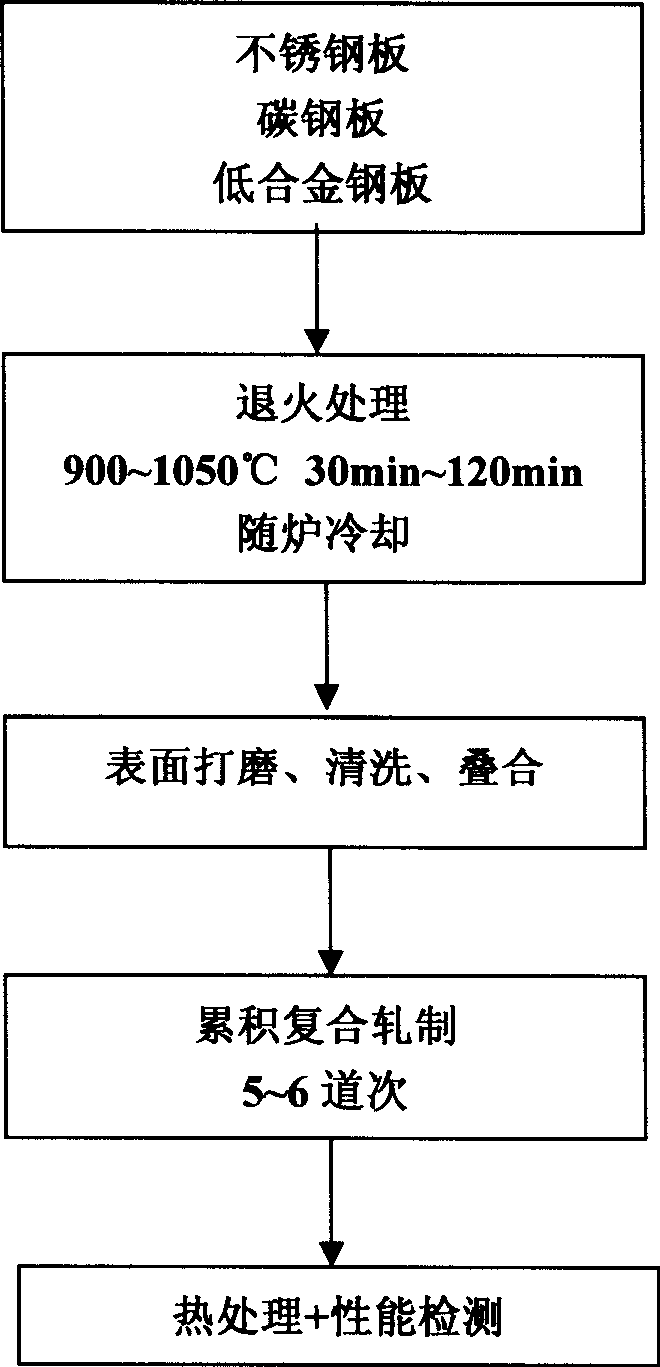

[0020] see figure 1 , the preparation method of the multilayer structure composite board of the present invention, specifically implement according to the following steps:

[0021] 1. The thickness of stainless steel is: 0.5mm~2.5mm; the thickness of carbon steel is 1.0mm~3.5mm, and the thickness of low alloy steel is 0.5mm~2.0mm.

[0022] First, anneal the stainless steel, carbon steel or low-alloy steel plate at 900°C to 1050°C, and cool with the furnace;

[0023] 2. Grinding the surface of the above stainless steel, carbon steel or low alloy steel plate to make the surface roughness Ra≤25μm;

[0024] 3. Clean the treated surface to remove oil, oxides and impurities on the surface of the plate;

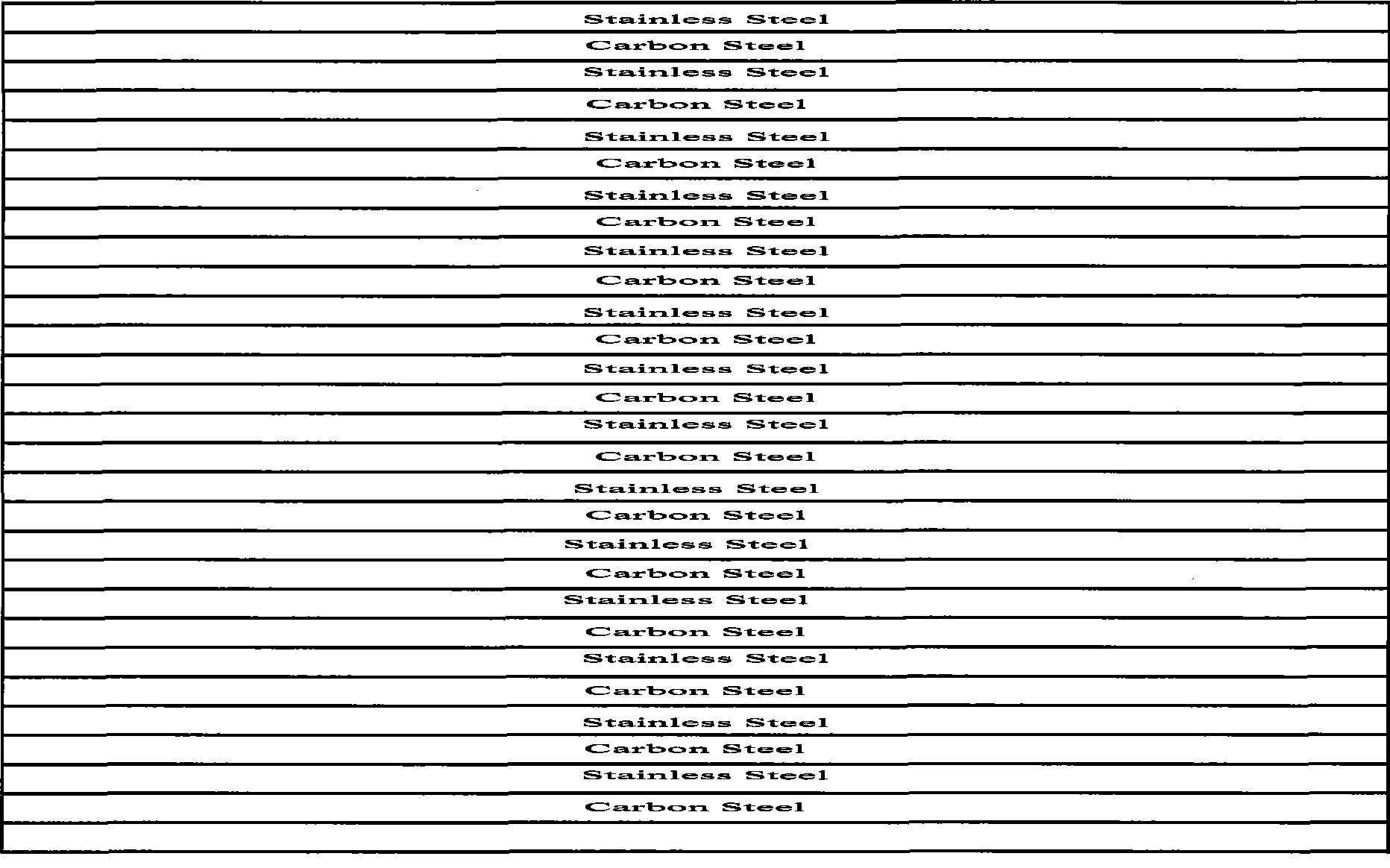

[0025] 4. Stack the cleaned stainless steel plate / stainless steel plate together, or stack the stainless steel plate / carbon steel plate / stainless steel plate together in the form of a hamburger, or stack the stainless steel plate / low alloy plate / stainless steel plate in the form o...

Embodiment 2

[0032] The difference between this embodiment and Embodiments 1 and 2 is that the surface treatment of stainless steel plates, carbon steel plates or alloy steel plates first uses chemical methods to remove oxides on the surface of the plates, that is, firstly carry out alkali washing and pickling to remove scale , and rinse with water or acetone solution; then use a wire brush / feather wheel to polish the surface of the plate, and finally clean the surface with water, acetone solution, etc. and dry it. Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com