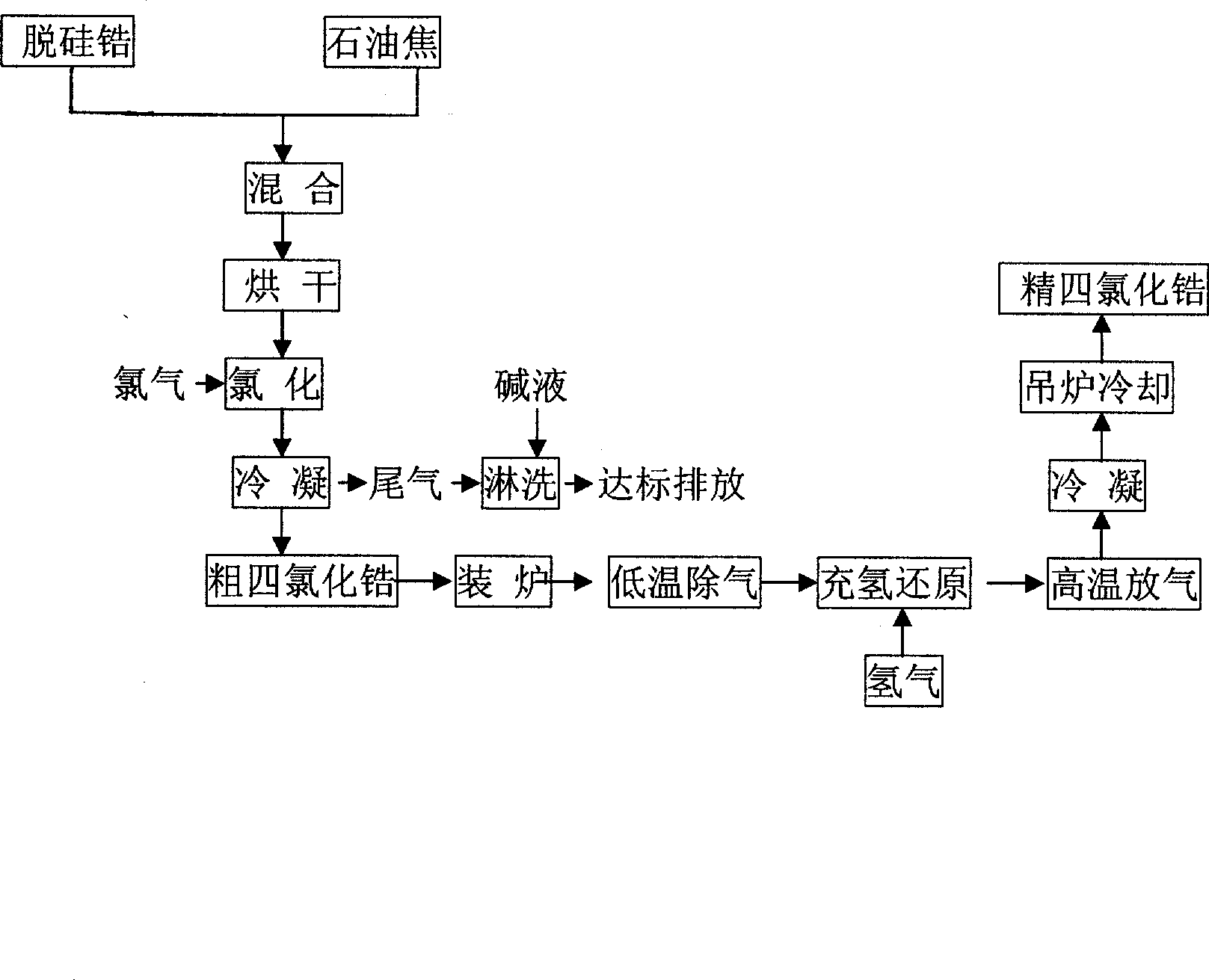

Preparation of refined zirconium tetrachloride

A technology of refined zirconium tetrachloride and zirconium tetrachloride, which is applied in the field of halide preparation, can solve the problems of high power consumption of refined zirconium tetrachloride, poor operating environment, low recovery rate, etc., so as to save power consumption , the effect of improving the recovery rate and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

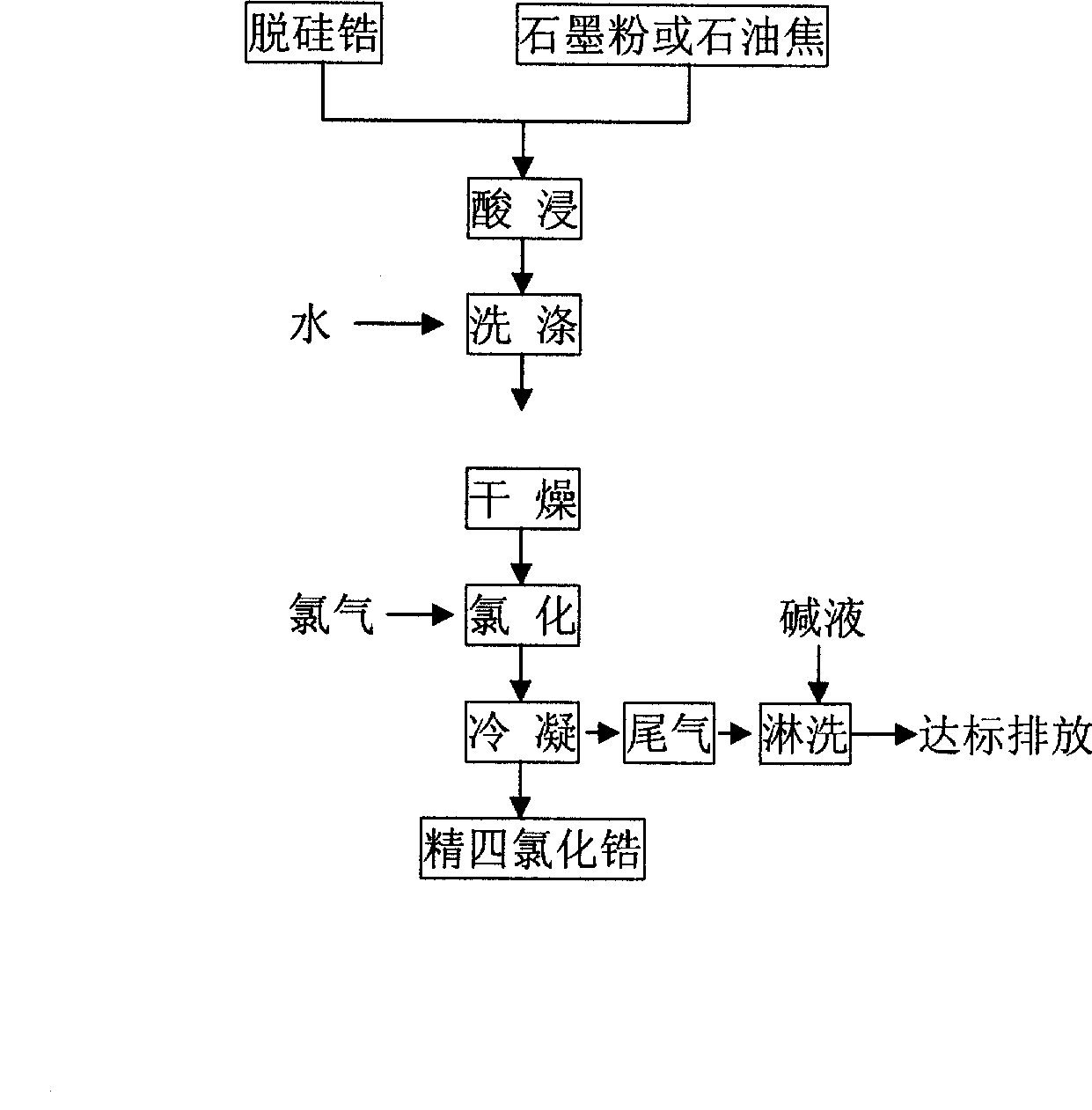

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of producing refined zirconium tetrachloride by boiling chlorination method, the desiliconized zirconium is crushed to a 325 mesh screen, the petroleum coke is crushed to a 160 mesh screen, the desiliconized zirconium and the petroleum coke are mixed in a weight ratio of 100:20, and the total material The weight is 1 ton, then joins in the reactor that is housed with concentration and is 6moL / L hydrochloric acid, and the hydrochloric acid volume in the still is 2m 3 , at a temperature of 40 ° C, stirring and reacting for 1 hour; the acid leaching mixture is centrifuged, washed with water to neutrality, and dried in a mixing dryer for 3 hours. In the boiling chlorination furnace of the filter, react with chlorine gas at 850°C for 20 hours, and the flow rate of chlorine gas is 0.7~0.8M 3 / hour, the refined zirconium tetrachloride with a content of 98.9% was obtained.

Embodiment 2

[0027] The preparation method for producing refined zirconium tetrachloride by the boiling chlorination method is to crush the desiliconized zirconium to a 400-mesh sieve, crush the graphite to a 100-mesh sieve powder, and mix the desiliconized zirconium and graphite in a weight ratio of 100:18. The total weight of the material is 1 ton, then join in the reactor that is housed with concentration of 4moL / L sulfuric acid, and the volume of sulfuric acid in the still is 1.5m 3 , at a temperature of 50 ° C, stirring and reacting for 2 hours; the acid leaching mixture is centrifuged by solid-liquid, washed with water to neutrality, and dried in a mixing dryer for 4 hours, and the dried material is continuously added to the nickel skeleton equipped with quartz cloth. In the boiling chlorination furnace of the bag filter, the reaction is carried out with chlorine gas at 820 ° C for 20 hours, and the flow rate of chlorine gas is 0.7 ~ 0.8M 3 / hour, the refined zirconium tetrachloride ...

Embodiment 3

[0029] The preparation method of producing refined zirconium tetrachloride by boiling chlorination method, crushing desiliconized zirconium to 400 mesh sieve, crushing petroleum coke into 200 mesh sieve fine powder, mixing desiliconized zirconium and petroleum coke in a weight ratio of 100:19, the material Gross weight is 1 ton, then joins in the reactor that is housed with concentration and is 4moL / L nitric acid, and the nitric acid volume in the still is 1m 3 , at a temperature of 35 ° C, stirring and reacting for 3 hours; the acid leaching mixture was centrifuged by solid-liquid, washed with water to neutrality, dried in a mixing dryer for 3 hours, and then the dried material was continuously added to the nickel skeleton equipped with quartz cloth In the boiling chlorination furnace of the bag filter, react with chlorine gas at 870 ° C for 24 hours, and the flow rate of chlorine gas is 0.7 ~ 0.8M 3 / hour, the refined zirconium tetrachloride with a content of 99.2% was obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com