Preparation of bacteria cellulose special-shaped product by microbial fermentation direct biosynthesis

A technology for bacterial cellulose and microbial fermentation, applied in the direction of microorganisms, microorganism-based methods, fermentation, etc., can solve problems such as increased product cost and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

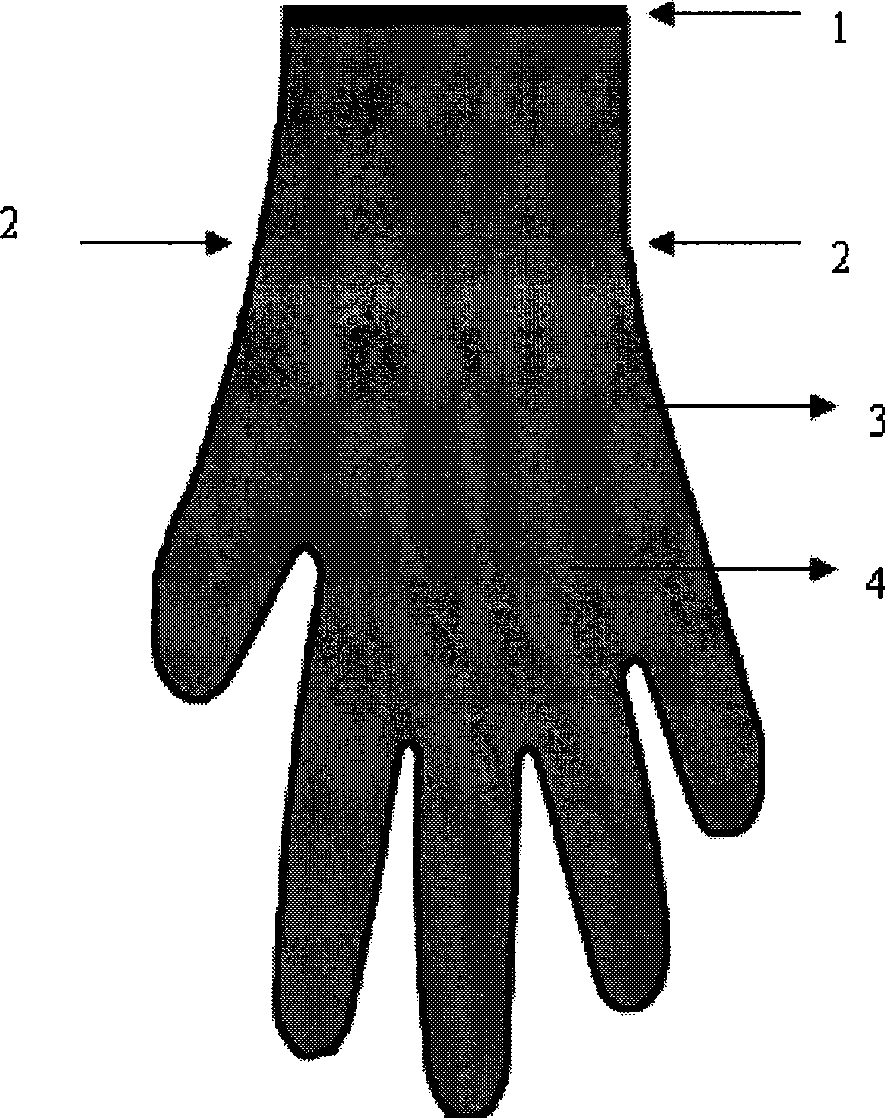

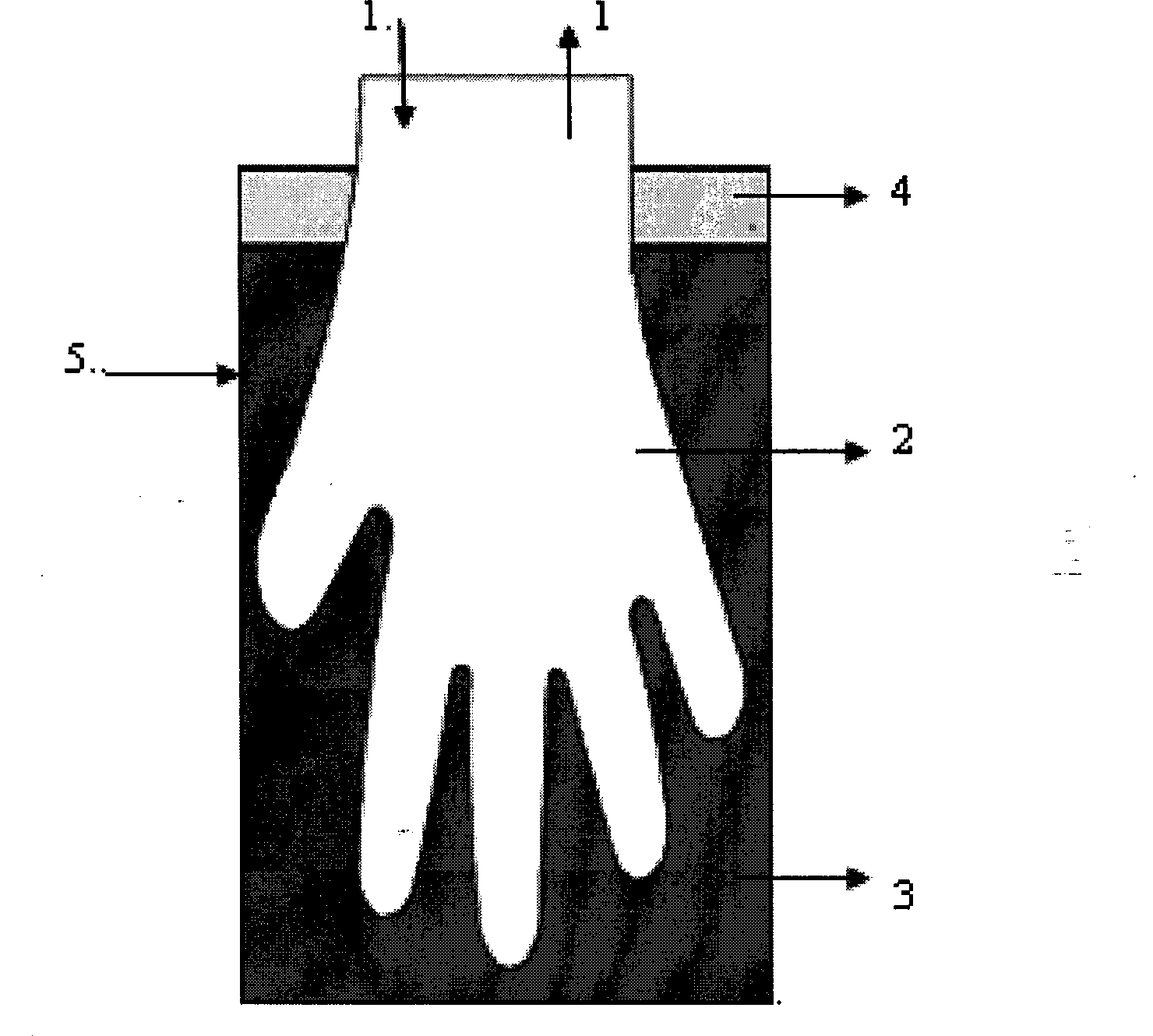

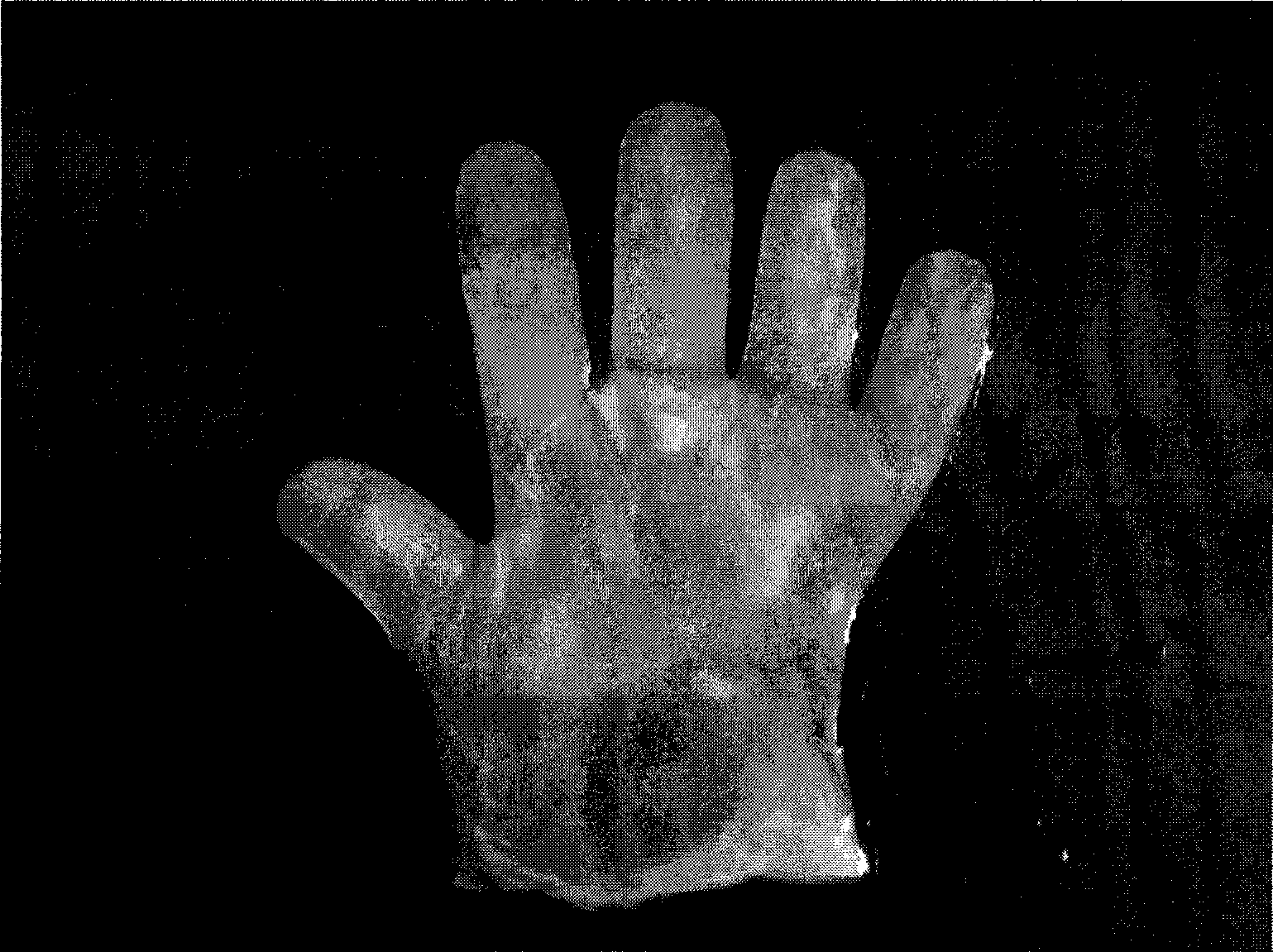

[0026] Gluconacetoacetobacter xylinum CGMCC No.1.1812, (purchased from China General Microorganism Culture Collection and Management Center) slanted seeds were inserted into the Erlenmeyer flask containing the seed medium, and after shaking at 160r / min at 30°C for 24h, wood Gluconoacetobacter seed is inserted in the Erlenmeyer flask that 500mLHS fermentation medium is housed with the inoculum amount of 5-20% (v / v), shakes up and pours into the hand-shaped fermentation container, after heat sealing, static at 30 ℃ After 10 days of culture, bacterial cellulose is attached to the surface of the inner wall of the container and synthesized after the fermentation. After peeling off the surface of the inner wall, the bacterial cellulose special-shaped product can be obtained. Then soak and wash in running water for 1-2d and then soak in 0.1mol / LNaOH solution for 1-2d to remove the culture medium and bacteria, and wash to neutrality (pH value about 7.2), such as image 3 As shown, th...

Embodiment 2

[0031] Bacterial classification and seed culture are the same as embodiment 1, and the inoculation amount of 5-20% (v / v) of Acetobacter xylinum seed is inserted in the Erlenmeyer flask that 300mLHS fermentation medium is housed, shakes up and pours into W-shaped In the fermentation container, after sealing, culture at 30°C for 10 days. After the fermentation, bacterial cellulose adheres to the surface of the inner wall of the container to synthesize. After peeling off the surface of the inner wall, put the special-shaped bacterial cellulose product in running water for 1-2 days, soak it in 0.1mol / L NaOH solution for 1-2 days to remove the culture medium and bacteria, and wash until neutral (pH value is about 7.2 ) and freeze-dried.

Embodiment 3

[0033]Bacterial classification and seed culture are the same as embodiment 1, and the inoculum size of 5-20% (v / v) of gluconoacetoacetobacter xylinum seed is inserted in the triangular flask that 300mLHS fermentation medium is housed, shakes up and pours into ring In the shaped fermentation container, after sealing, it was cultured at 30°C for 10 days. After the fermentation, the bacterial cellulose was attached to the surface of the inner wall of the container and synthesized. After peeling off the surface of the inner wall, put the special-shaped bacterial cellulose product in running water for 1-2 days, soak it in 0.1mol / L NaOH solution for 1-2 days to remove the culture medium and bacteria, and wash until neutral (pH value is about 7.2 ), and then freeze-dried, the results are as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com