Digital wireless well workover weight-indicating anti-collision instrument

A digital and wireless technology, applied in drilling equipment, automatic drilling control system, earthwork drilling and production, etc., can solve the problems of low actual precision, rework, increase of labor intensity and construction cost, etc., to ensure intuitiveness and The effects of accuracy, instrument installation and maintenance convenience, and direct and effective data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the accompanying drawings.

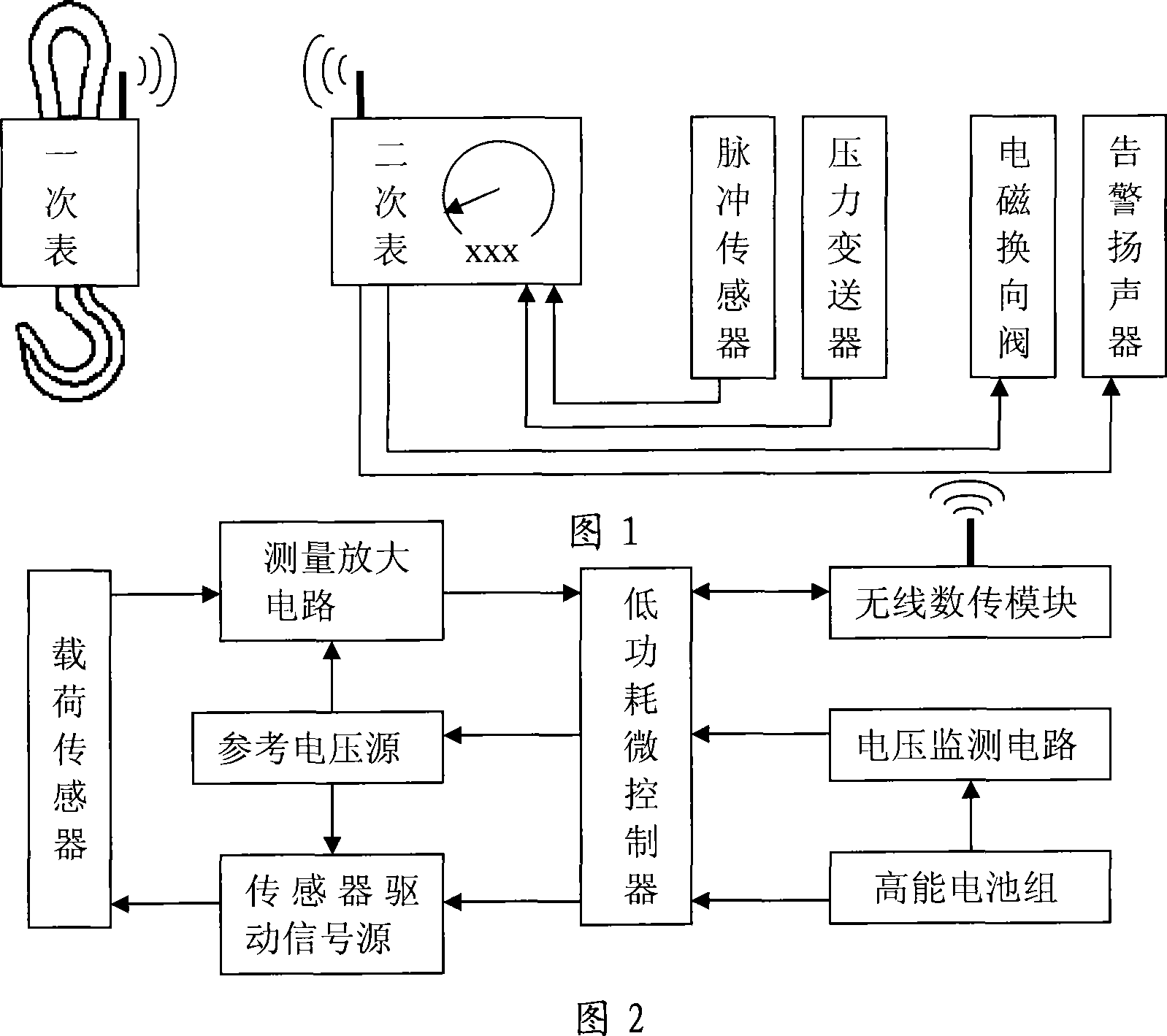

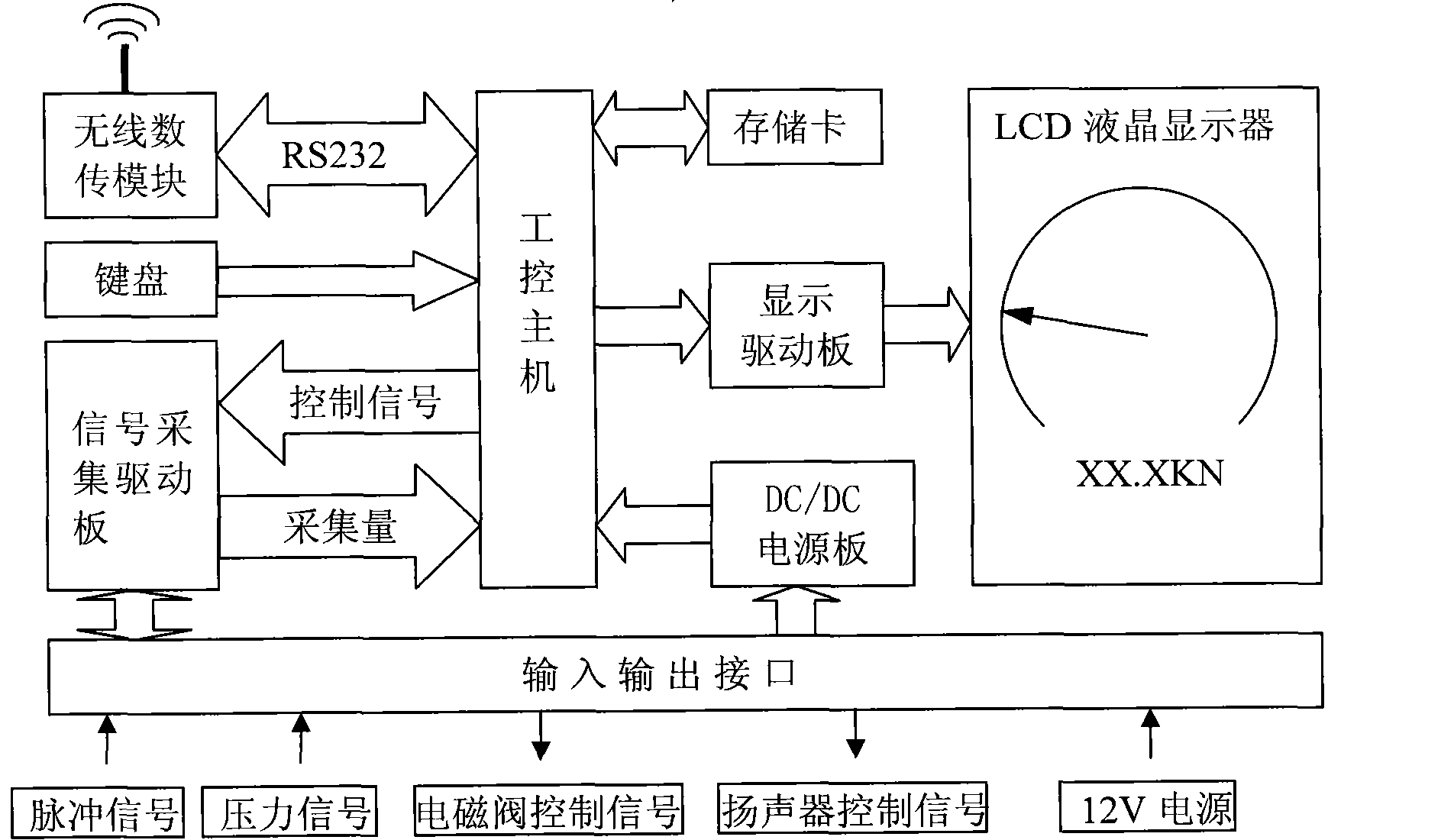

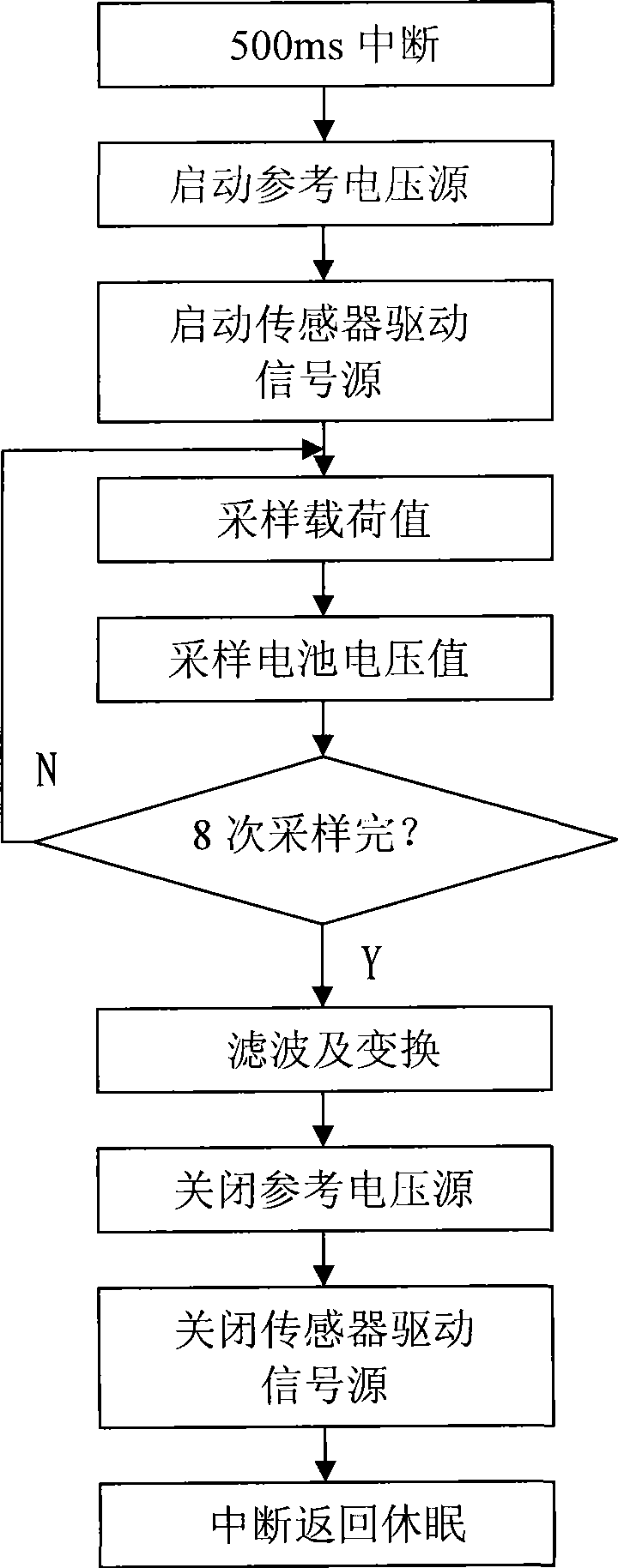

[0027] As shown in Figure 1, the present invention is composed of a primary meter, a secondary meter, a pressure transmitter, a pulse sensor, an electromagnetic reversing valve, and an alarm speaker, and data transmission is performed between the primary meter and the secondary meter through a wireless data transmission module; The pressure transmitter, pulse sensor, electromagnetic reversing valve, and alarm speaker are respectively connected to the secondary meter cable; the secondary meter collects the input signal of the pressure transmitter and pulse sensor, and controls and drives the electromagnetic reversing valve and the alarm speaker; among them, The primary meter mainly includes a load sensor, a sensor driving signal source, a reference voltage source, a measurement amplifier circuit, a high-energy battery pack and its voltage monitoring circuit, a wireless data tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com