Monitoring method for energy-saving emission reduction real-time quantization of dry method cement product line

A technology of energy saving and emission reduction, dry process cement, applied in cement production, clinker production, energy saving ICT, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

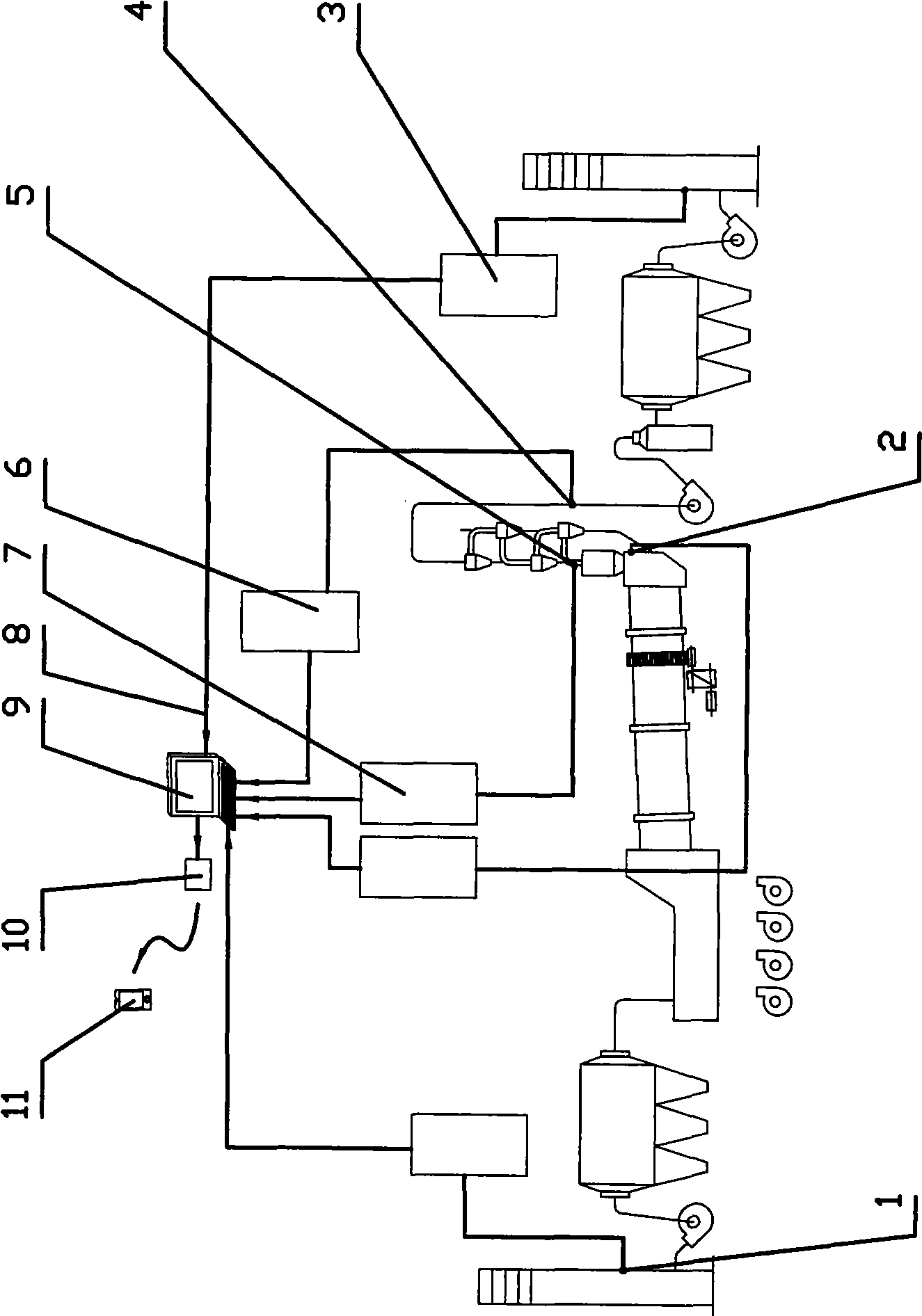

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] A method for real-time quantitative monitoring of energy saving and emission reduction in a dry-process cement production line. The cement production line includes a rotary kiln, a calciner connected to the rotary kiln, and a high-temperature gas analyzer 7 used in the monitoring method, a computer 9 and a medium-temperature Gas analyzer 6 and dust measuring instrument 3, chimney, etc. For the monitoring method described, see figure 1 A set of high-temperature gas analyzer 7 is respectively installed in the tail smoke chamber 2 of the rotary kiln and the outlet 5 of the decomposition furnace. Analyzer, its function is to continuously measure and analyze the content of CO, O2 and NO in the high-temperature waste gas of rotary kiln and decomposition furnace on-line. The two high-temperature gas analyzers 7 are respectively connected to the computer 9 with a sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com