Patch and patch preparation

A patch and preparation technology, applied in the field of patch preparations, can solve the problem of insufficient self-retention performance as a patch material, and achieve the effect of excellent operability and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

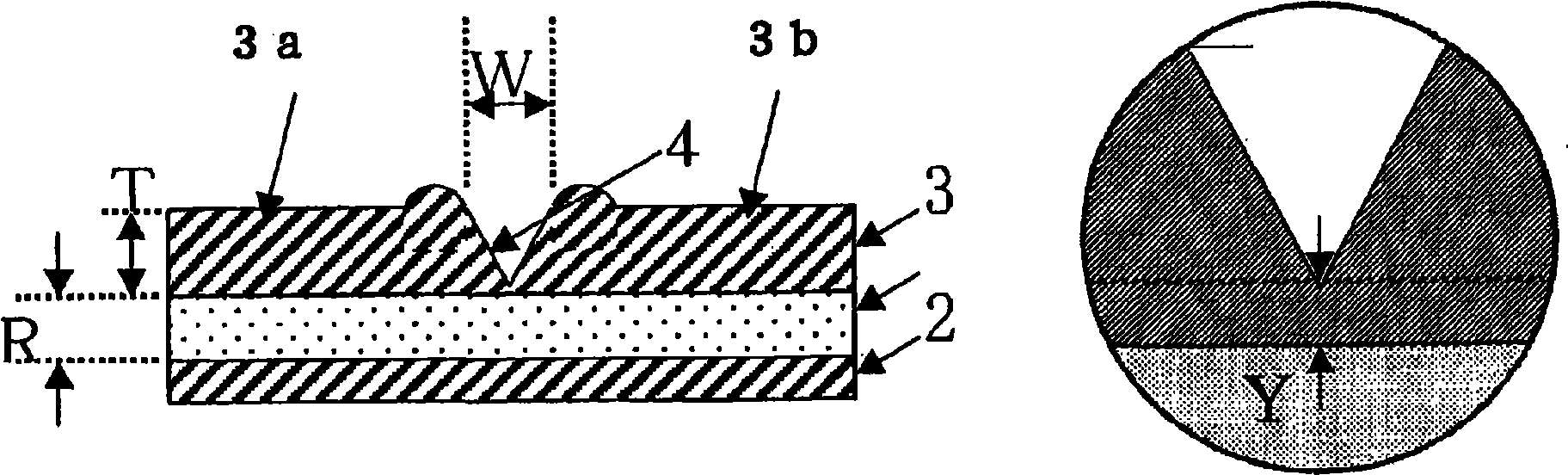

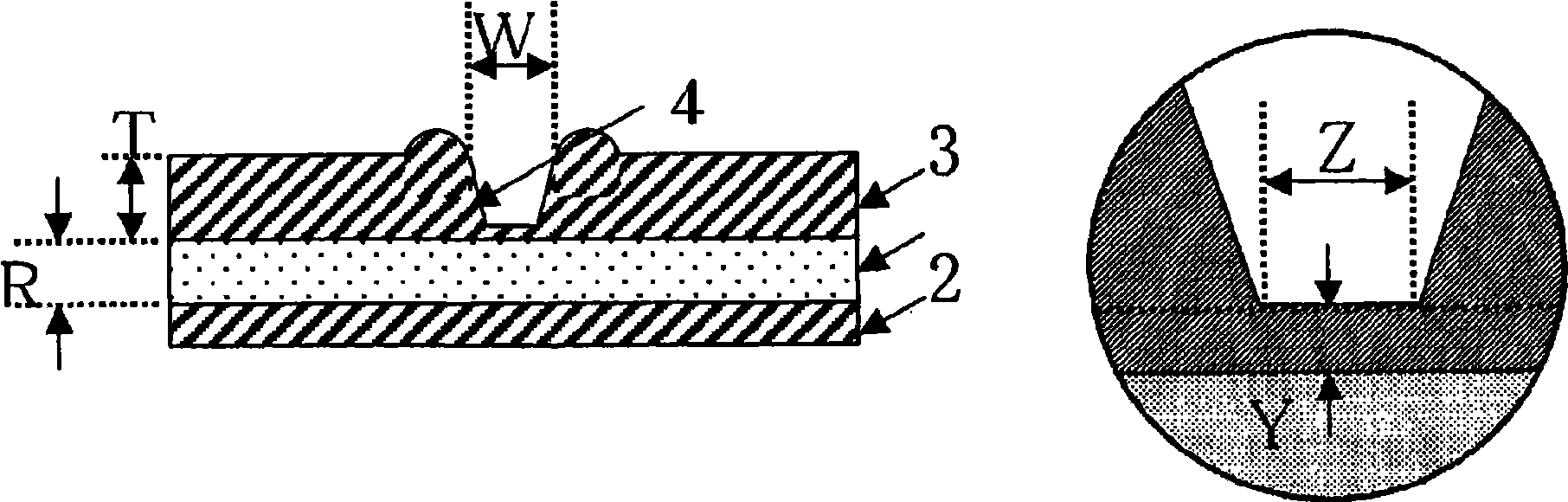

Method used

Image

Examples

Embodiment 1

[0094] The grooves of the liner itself form:

[0095] Various polyethylene terephthalate films (PET) having bending resistance and thickness shown in Table 1 were used as liners. By using the laser marking machine ML9110 (manufactured by Keyence, CO. 2 Laser, power consumption: 450VA) laser cutting device (manufactured by DaishoKagaku Kikai Kogyo K.K.) and simultaneously regulate the laser output and feed rate, form grooves on the pad, and then cut the pad into a square of 32mm×32mm to Samples 1 to 7 having various groove shapes shown in Table 1 were prepared.

Embodiment 2

[0097] Prepare patch formulations with grooved liners:

[0098] 1. Preparation of Pressure Sensitive Adhesives

[0099] 30 parts of low molecular weight polyisobutene (viscosity average molecular weight: 60,000, HIMOL6H, manufactured by Nippon Petrochemicals Co., Ltd.) and 20 parts of high molecular weight polyisobutylene (viscosity average molecular weight: 990,000, VISTANEX MML-80, manufactured by Exxon Chemical) were dissolved in ethyl alcohol in alkane to prepare a polyisobutylene-based pressure-sensitive adhesive solution (solid content concentration: 30% by weight). 6 parts of polybutene (viscosity average molecular weight: 1,260, HV-300F, manufactured by Nippon Petrochemicals Co., Ltd.) and 14 parts of alicyclic petroleum resin (softening point: 100° C., ARKON P-100, manufactured by Arakawa Chemical Industries Co., Ltd.) were added into the solution and dissolve with stirring. A hexane solution of tulobuterol (TBL) was added to the resulting solution to have a content...

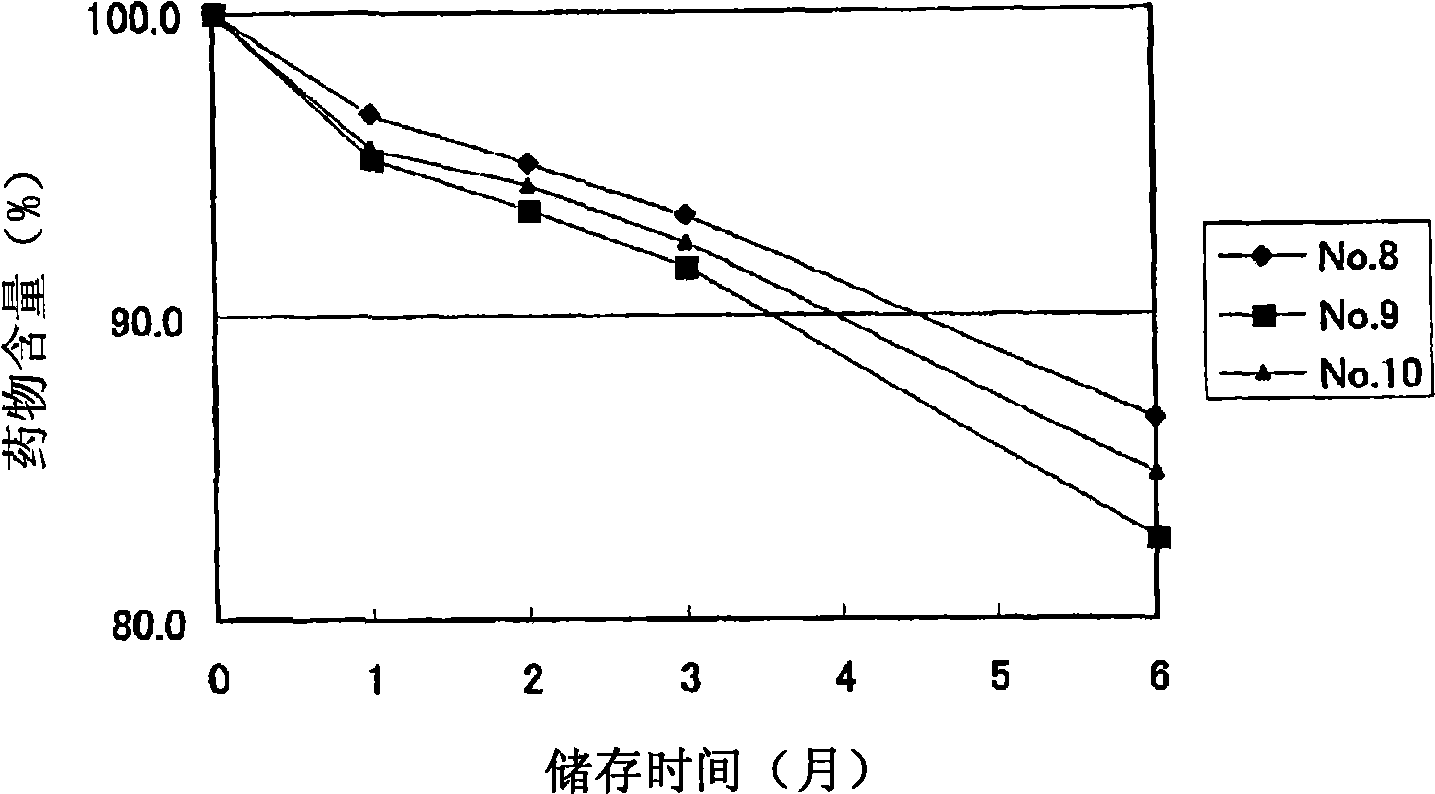

Embodiment 3

[0113] Storage test:

[0114] The packaged patch formulations were stored at 40°C and 75% relative humidity for one, two, three or six months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com