Cast-coated paper

A cast-coated paper and coating technology, which is applied in coating, papermaking, paper coating, etc., can solve the problems of operability, reduced productivity, difficulty in obtaining glossy printing quality of white paper, and difficulty in producing air-cleaning effect cast-coated paper. , to achieve the effect of good coating suitability, good printing quality and high gloss of white paper

Inactive Publication Date: 2009-07-22

NIPPON PAPER IND CO LTD

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when photocatalyst titanium dioxide is simply used in the existing composition and production method, the change in the physical properties of the coating leads to a decrease in workability and productivity, and it is difficult to obtain sufficient white paper gloss and excellent printing quality. Cast coated paper with air cleaning effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

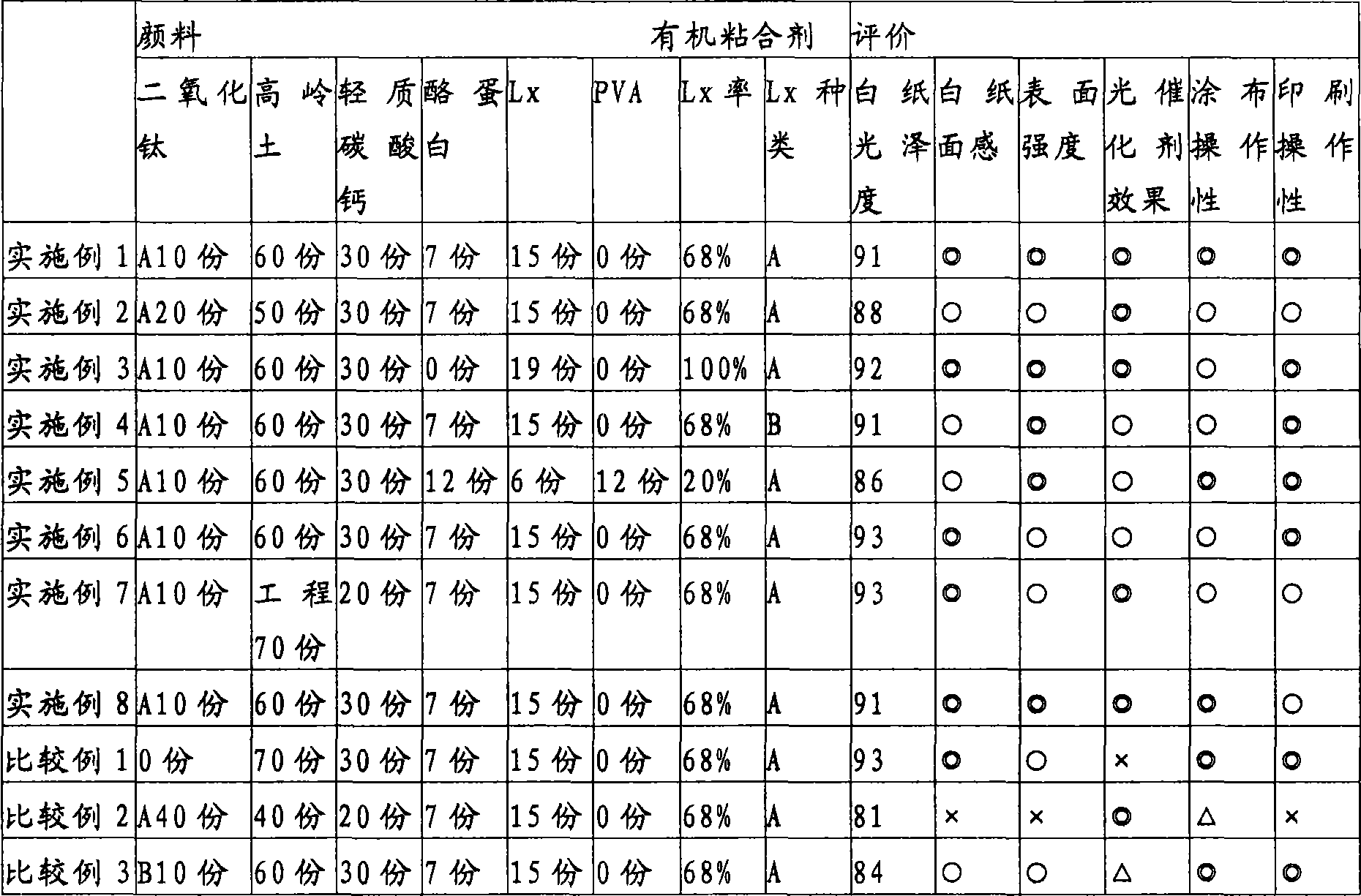

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a cast-coated paper which is excellent in coated-paper quality and printability and functions to decompose a harmful substance upon irradiation with light. The cast-coated paper is obtained by forming on a raw paper a cast coating layer comprising a pigment and an adhesive as major components and pressing the cast coating layer in a wet state against a heated mirror surface of a drum to dry and finish the layer. The cast-coated paper is characterized in that the cast coating layer contains titanium oxide having an average secondary-particle diameter of 300-2,000 nm in an amount of 1-30 parts by weight per 100 parts by weight of the pigment and the titanium oxide has been treated beforehand by mixing it with a silica sol or alumina sol in a titanium oxide / silica sol or alumina sol proportion of from 2 / 1 to 1 / 2.

Description

Technical field [0001] The present invention relates to a cast-coated paper having excellent coating suitability and good printing suitability due to the maintenance of an appropriate coefficient of friction and an excellent air cleaning effect. Background technique [0002] With the increase in the level of concern for the living environment, the demand for removal of harmful substances in daily life such as malodors has increased, and the attention has been focused on titanium dioxide. Titanium dioxide has been used as a pigment with excellent opacity and whiteness in papermaking applications. It is also known that titanium dioxide particles can use light energy to initiate a redox reaction, thereby decomposing various harmful substances in the air. Therefore, development has been carried out. Titanium dioxide is loaded on paper to take advantage of this phenomenon. For example, there is disclosed a photocatalyst paper in which a water-soluble polymer, titanium dioxide, and oth...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21H19/36D21H19/38

CPCD21H25/14D21H19/385D21H19/38D21H19/56D21H19/50D21H19/54D21H19/80D21H19/66D21H19/84D21H19/36D21H19/40D21H21/52Y10T428/25

Inventor 绀屋本博久津轮幸二冈本匡史甲斐秀彦大笼幸治越智隆石桥范之林伸匡

Owner NIPPON PAPER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com