Energy-saving explosion-proof electric heater for pot

An electric heater and electric heating technology, applied in the direction of tank cars, containers, large containers, etc., can solve the problems of high failure rate of heaters, reduced heat transfer of electric heaters, induced fouling, carbonization and coking, etc., to reduce maintenance costs and maintenance time, the rate of enhanced heat transfer, and the effect of accelerating the rate of dilution and viscosity reduction

Inactive Publication Date: 2010-11-10

NANYANG YITONG EXPLOSION-PROOF ELECTRIC CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(2) Crude oil is a mixture of various hydrocarbons, often containing solid and semi-solid substances such as asphaltenes, colloids, inorganic substances, and oil-water emulsions; at the same time, crude oil often contains sediment, scale, rust, corrosion products and Biological and other sediments; in addition, there are various salts dissolved, such as bicarbonate, sulfate, chloride, silicate and other sediments, these substances are easy to adhere and deposit on the heat dissipation surface of the electric heater, forming a thermal conductivity The lower heat resistance layer will seriously affect the heat transfer of the electric heater and reduce it, and will induce scaling, carbonization and coking, etc., which will lead to a vicious increase in thermal resistance, greatly reducing the thermal efficiency of the electric heater and reducing energy consumption. greatly increase

(3) With the prolongation of the use time of the heater, the error between the displayed thermal efficiency index value and the nominal value of the manual will become larger and larger, so that the heat generated by the electric heater cannot be effectively utilized

(4) Due to the low rate of heat transfer and the influence of adhered dirt and coke, the temperature of the oil stored in the tank has not yet risen to the required set value, while the temperature of the heat transfer oil in the heater has risen to the dry burning protection When the value is above 120°C, the dry burning protection circuit will control the heater to stop working. Due to the limited heat stored in the heat transfer oil, its temperature will soon drop below 120°C, and the heater will restart heating, thus making the electric heater work. In the state of frequent start and stop, the oil temperature of the oil in the tank can not go up all the time, and there are many unheated dead zones, which not only consumes a lot of energy, but also has poor viscosity reduction effect. Silicon-controlled phase-shift control or AC contactor contact control mode, frequent start and stop, easy to cause strong impact on the power grid, serious harmonic pollution, high heater failure rate, poor safety and reliability, high maintenance costs and other disadvantages

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

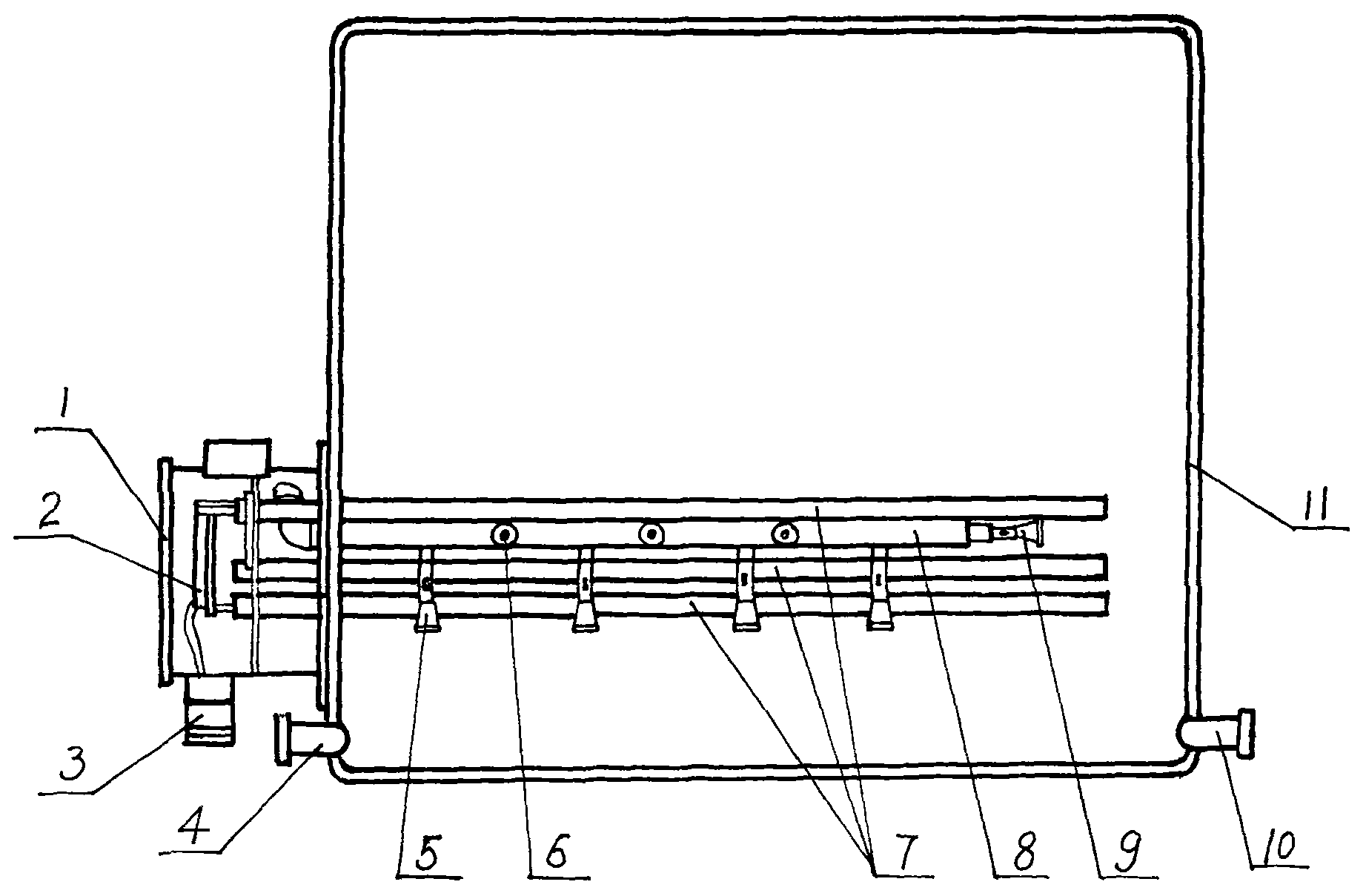

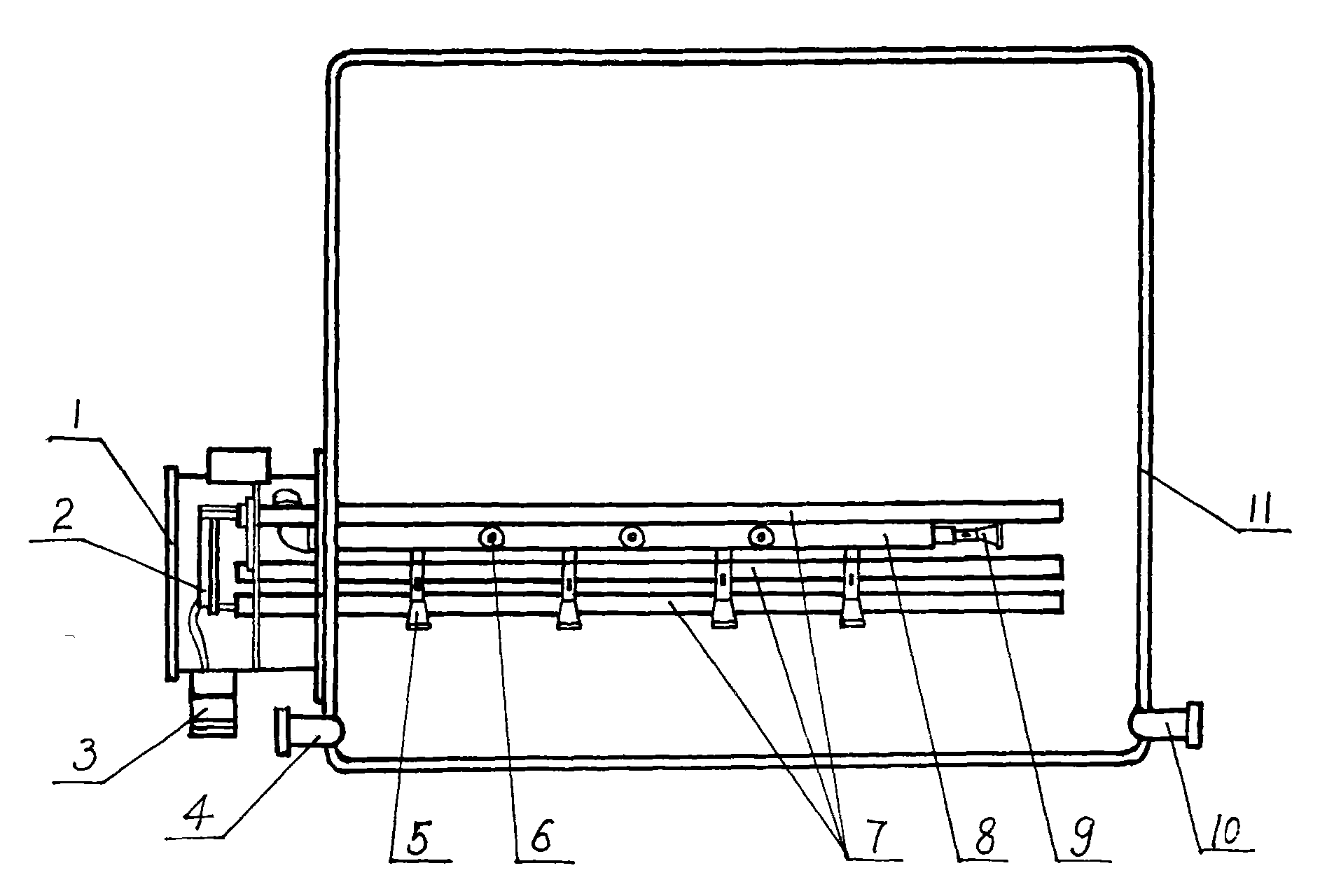

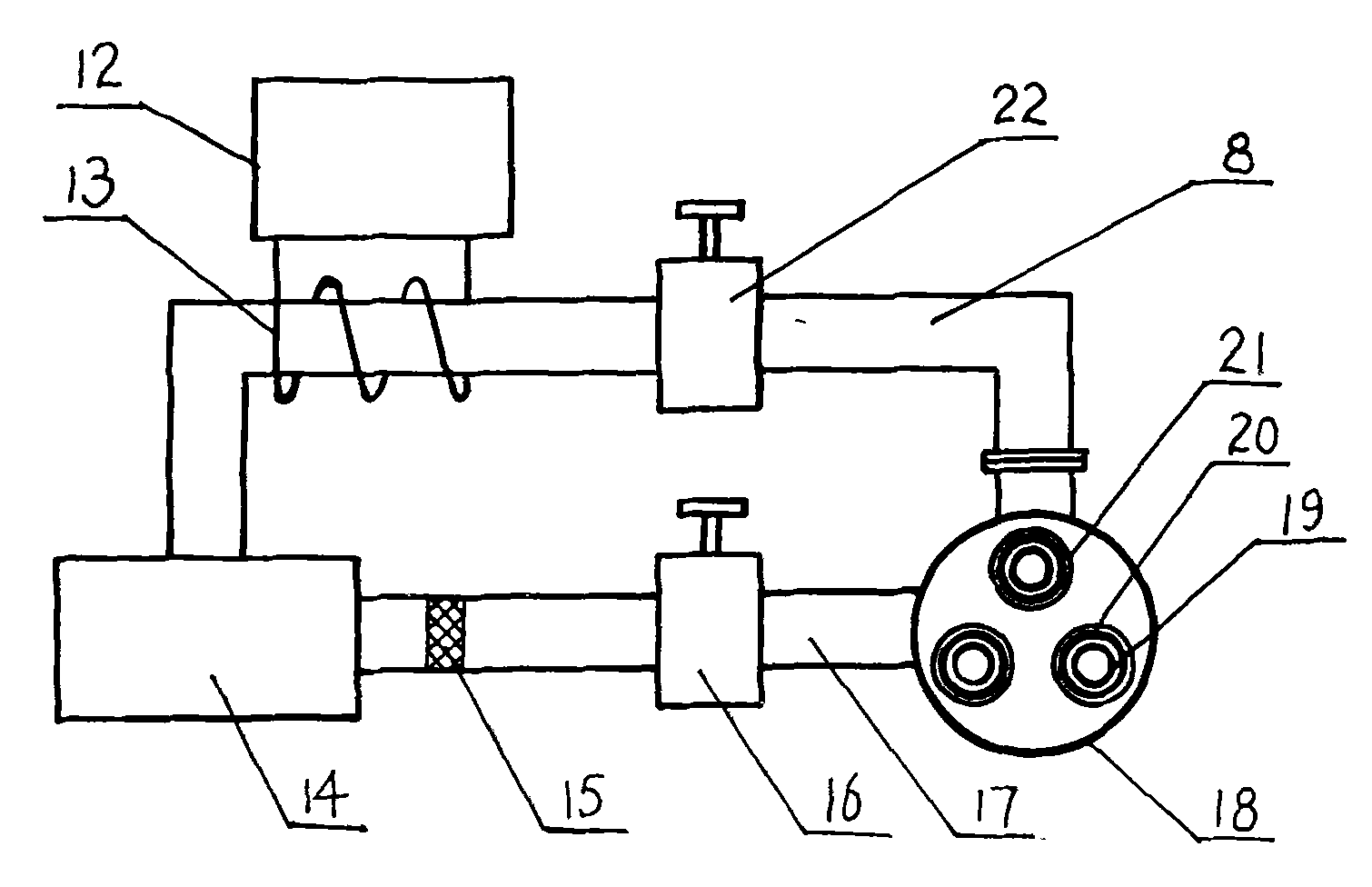

The invention relates to an energy saving explosion prevention electric heater for pots, which is provided with a heating device which extends into a pot from the outside of the pot and a flow jet and heat transfer device, wherein the flow jet and heat transfer device consists of a flow jet pump and a flow jet pipe which is connected with the flow jet pump and extends into the pot. A liquid inletof the flow jet pump is communicated with a liquid storage pot through a liquid suction pipe, and the part of the flow jet pipe extending out of the pot is provided with an electromagnetic scale preventing and scale removing device. The heating device consists of a plurality of electric heating components, and is arranged in a lower position in the liquid storage pot parallel to the flow jet pipe, wherein the electric heating components and the part of the flow jet pipe extending out of the pot are coated with an explosion prevention box, and the inside of the explosion prevention box is provided with a heating monitoring device. The energy saving explosion prevention electric heater can prevent the surface of the electric heater from scaling and coking effectively, and has the advantagesof high heat energy transfer speed, high electric heat efficiency, long service life, obvious energy saving effect, good explosion prevention safety performance, convenient operation and maintenance,and the like.

Description

Energy-saving explosion-proof electric heater for tank Technical field The invention belongs to the technical field of heating equipment, in particular to an energy-saving explosion-proof electric heater for tanks used for heating chemical liquids such as crude oil in tanks. Background technique In the production, storage and transportation fields of petroleum and chemical industries, it is often necessary to heat and dilute crude oil or chemical liquids to enhance their fluidity and have higher requirements for their explosion-proof performance. In the existing heating technology, the commonly used heating device is to place a number of electric heating cores in a closed sleeve and fill it with heat-conducting oil, and then install the heating device in the middle of the oil storage tank for electric heating. The core body generally adopts power frequency electromagnetic heating, mineral heating cable or electric heating tube, etc. The electric heating core body generates hea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65D88/74B65D90/48

Inventor 马经刚燕远见赵兴海

Owner NANYANG YITONG EXPLOSION-PROOF ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com