Apparatus and method for treating water containing white oil stain

A technology of oily sewage and white oil, applied in the direction of heating water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large power consumption, complex structure, difficult maintenance, etc. Achieve uniform distribution of liquid flow, high oil-water separation efficiency, and prevent short circuit and channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited thereto.

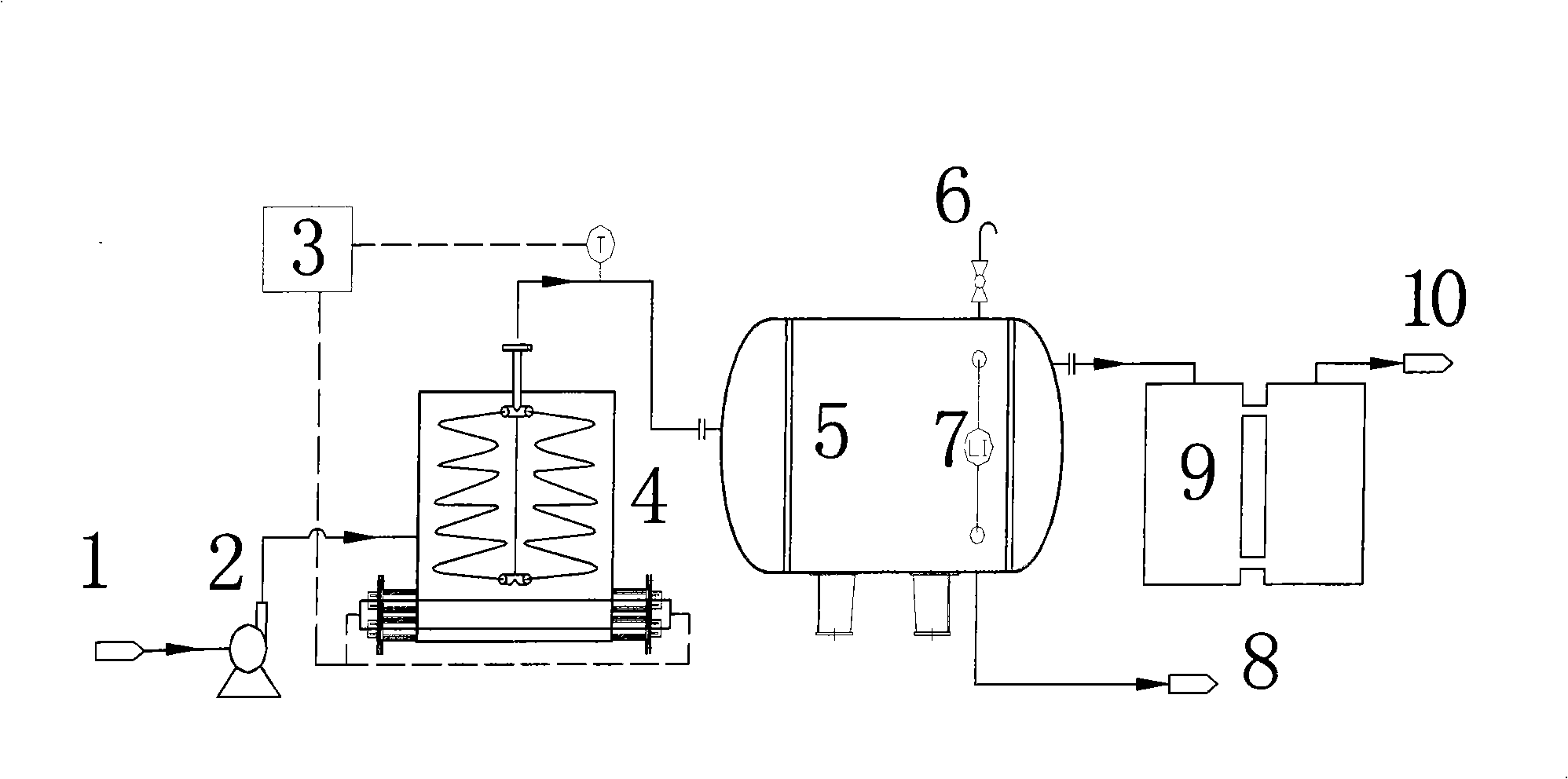

[0024] Accompanying drawing 1 is that the present invention is used for the schematic diagram of white oil sewage treatment process method. Design flow 0.4m 3 / h, the raw material 1 is connected to the preheater 4 through the raw material pump 2 valve and the sealed pipeline; the preheater 4 is provided with a temperature control box 3 to keep the temperature of the preheater constant; Feed port, the white oil separated from the upper discharge port of the oil-water separation tank 5 enters the white oil storage tank 10 through the white oil buffer tank 9, and the standard waste water 8 separated from the lower discharge port of the oil-water separation tank 5 is directly discharged. The oil-water separation tank is a stainless steel or carbon steel cylinder; the coalescing packing section ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com