Hard road bitumen compositions and preparation process

A kind of asphalt composition and road asphalt technology, which is applied in the direction of roads, roads, building structures, etc., can solve the problems of low temperature performance, fatigue resistance and aging resistance, limited and short-term improvement of the overall performance of the road surface, and achieve high temperature stability. Performance and anti-aging performance, simple preparation method, and the effect of reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

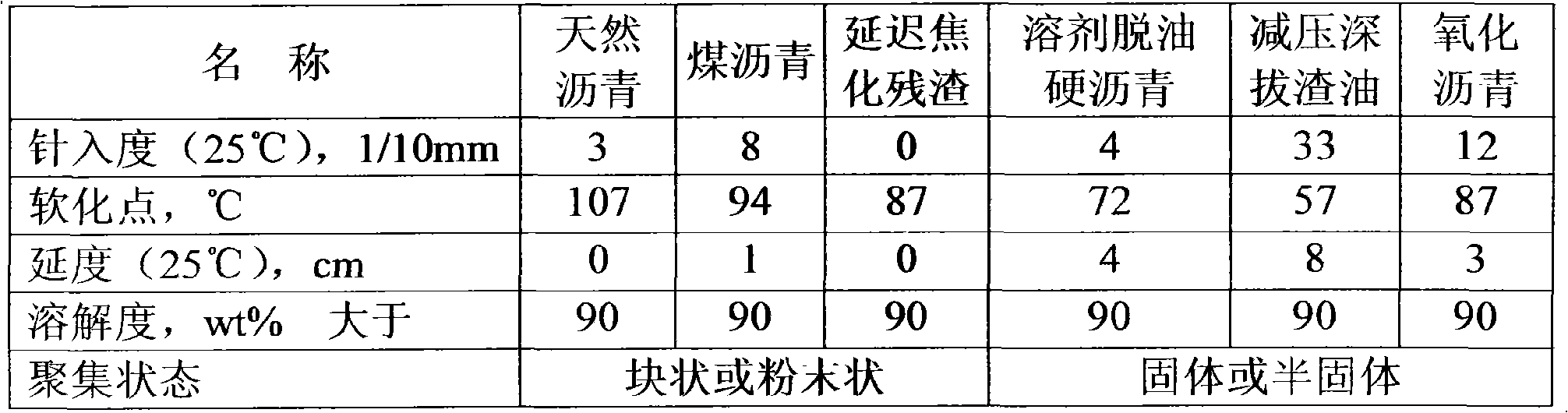

Method used

Image

Examples

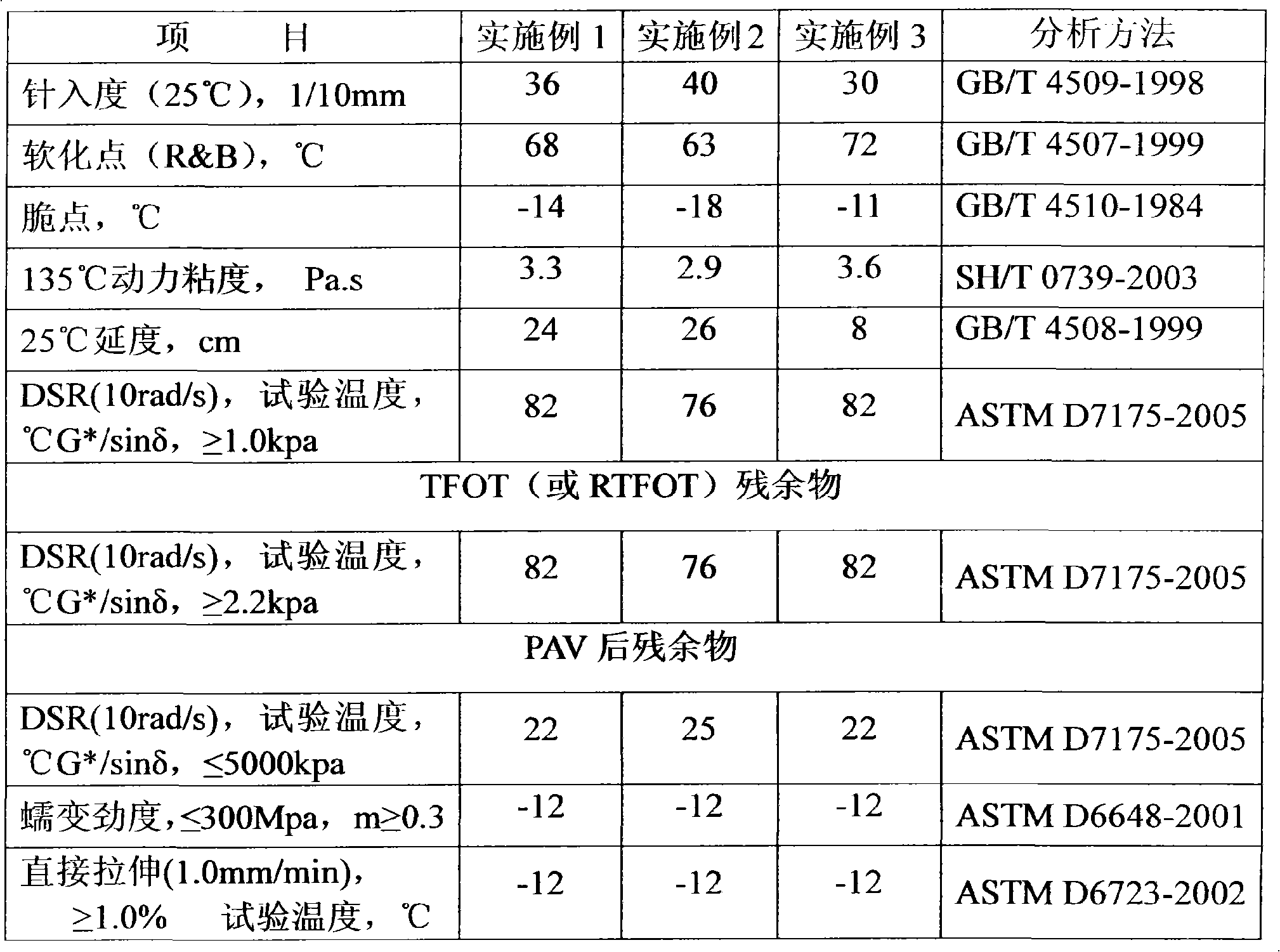

Embodiment 1

[0033]Respectively with 230 parts of coal tar pitch, 160 parts of natural pitch, 280 parts of oxidized pitch, 330 parts of lubricating oil phenol refining minus four-line extraction oil (property: initial boiling point is 387 ℃, aromatic content is 47.16wt%, wax content is 0.17 wt%), 86 parts of oxidized fatty acid residue (properties: initial boiling point of 383°C, aromatic content of 28.41wr%, wax content of 0.09wt%) were added to the reactor, preheated and co-dissolved at 110°C for 2 hours . Add 498 parts of Tahe asphalt into the above mixture, heat and melt, then shear and mix at 165°C and 3300 rpm for 20 minutes. Then add 16 parts by weight Ca(OH) 2 : thiourea=3:13 chemical modifier, and after maintaining the above conditions and mixing for 20 minutes, high-performance hard road asphalt was prepared, and the performance test results are shown in Table 3.

Embodiment 2

[0035] 244 parts of solvent deoiled hard asphalt, 120 parts of delayed coking residue, 200 parts of natural asphalt, 320 parts of solvent deasphalted heavy deasphalted oil (property: initial boiling point is 417 ℃, aromatic content is 51.02wt%, wax content 1.57wt%), 60 parts of catalytic cracking oil slurry (properties: initial boiling point is 380°C, aromatic content is 53.23wt%, wax content is 0.87wt%) into the reactor, preheated at 130°C A total of 3 hours of dissolution. Add 625 parts of asphalt in the sand to the above mixture, heat and melt, and shear and mix for 20 minutes at a speed of 3300 rpm at a temperature of 170 ° C, then add 31 parts by weight of NaOH: zinc naphthenate: butanedi Acid anhydride=1:12:18 chemical modifier, and after maintaining the above conditions and mixing for 20 minutes, a high-performance hard road asphalt was prepared. The performance test results are shown in Table 3.

Embodiment 3

[0037] Respectively, 200 parts of solvent deoiled hard asphalt, 144 parts of oxidized asphalt, 200 parts of natural asphalt, 106 parts of vacuum deep-drawing residue oil, and 330 parts of lubricating oil furfural refined minus four-line extraction oil (property: initial boiling point is 392 ° C, Aroma content is 47.74wt%, wax content is 0.38wt%), and 60 parts of waste machinery oil with an initial boiling point of 430°C are respectively added to the reactor, and preheated and co-dissolved at 110°C for 1 hour. Add 517 parts of Iranian Ding deasphalt to the above mixture, after heating and melting, shear and mix for 20 minutes at a speed of 3000 rpm at 160 °C, then add 43 parts by weight of Ca(OH) 2 : iron naphthenate: thiourea=3: 28: 12 chemical modifier, and after maintaining the above conditions and mixing for 20 minutes, high-performance hard road asphalt was obtained, and the performance test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com