Catalytic reforming plant for solid-oxide fuel battery

A solid oxide, catalytic reforming technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of complex reformer structure, insufficient miniaturization, large equipment investment, etc., and achieve a simple structure. , Easy to stack and assemble, the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

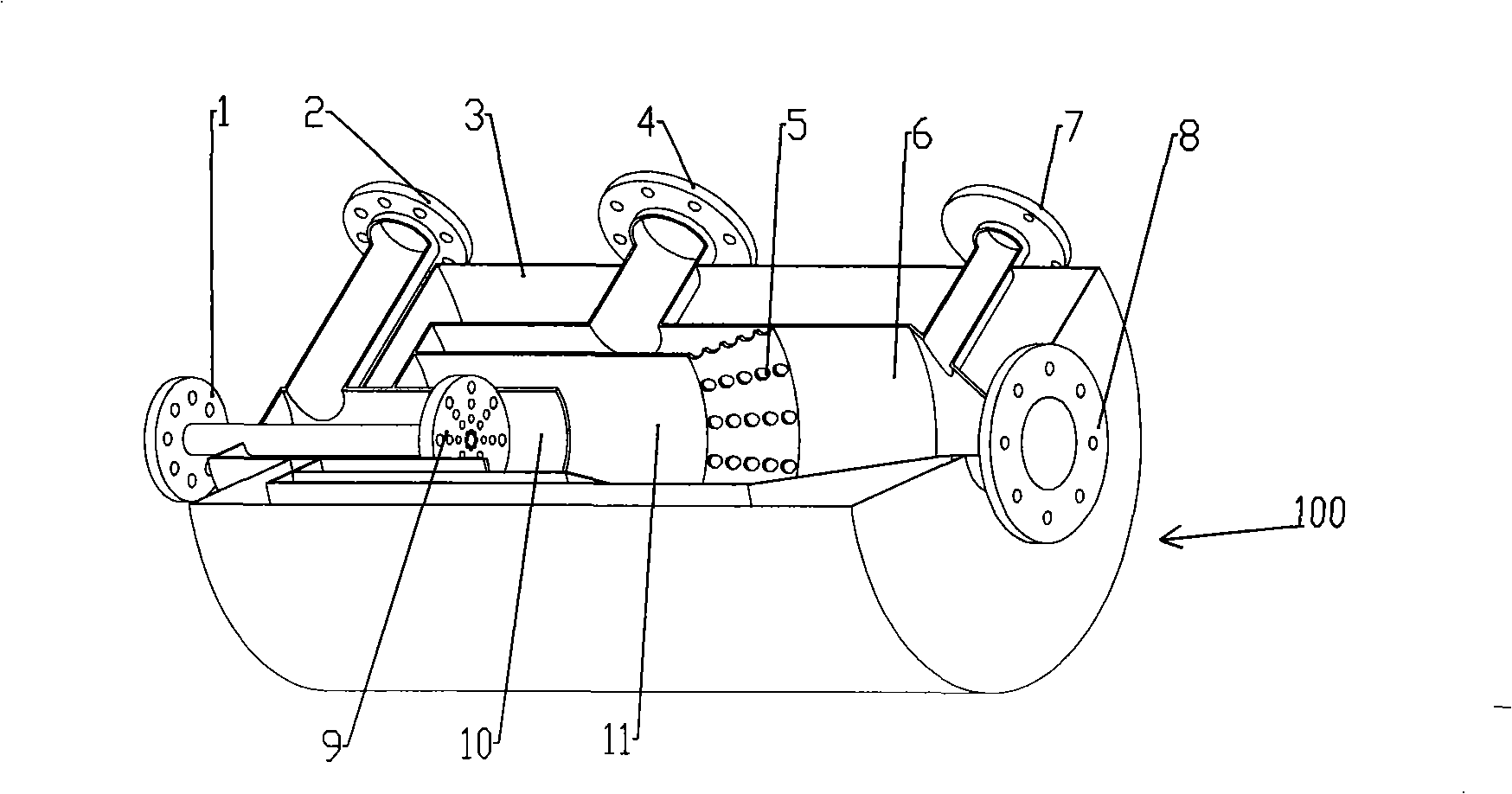

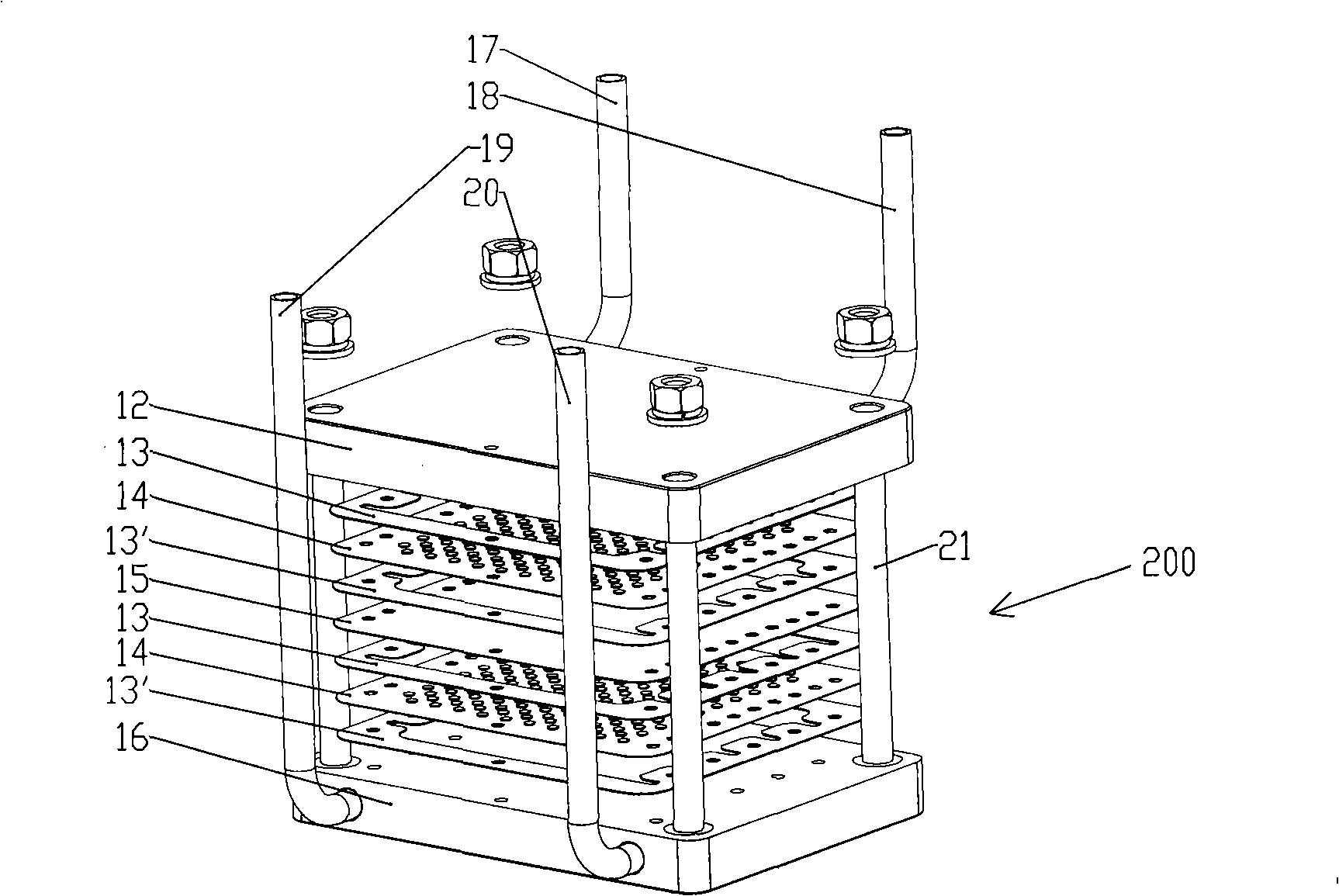

[0030] As shown in FIG. 1 , the intensive reformer is used in a fuel cell system of a solid oxide fuel cell, which generates electric energy through a reduction reaction of a reformed gas. Therefore, the intensive reformer has the function of supplying reformed gas to the cell stack in the solid oxide fuel cell system.

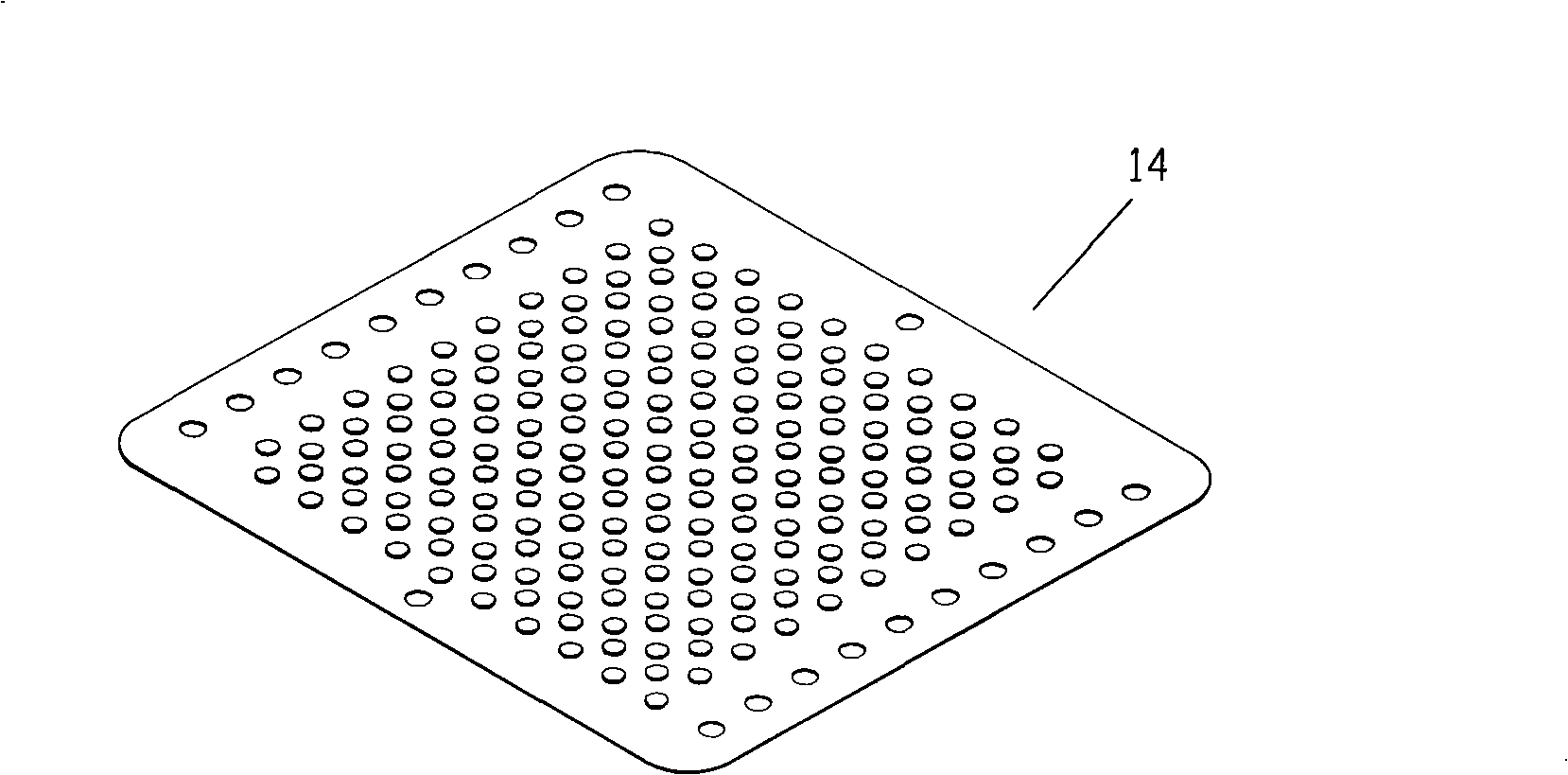

[0031] The reformer includes: a start-up combustor 100, which provides thermal energy to the reformer 200 for endothermic steam reforming through the ignition and combustion of natural gas and air; The catalyst in unit 14 steam reforms natural gas with water to produce hydrogen-containing reformed gas.

[0032] Therefore, in order to save energy consumption, the start-up combustor 100 is connected to the reformer 200 through a very short thermal insulation pipeline or directly assembles the start-up combustor 100 and the refo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com