Paper pulp basin and method for producing the same

A production method and pulp technology, applied in the pulp basin and its production field, can solve the problems of easy breakage, non-environmental protection and heavy weight of plastic products, and achieve the effects of not easy breakage, saving renewable resources, and less moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Confetti 4% White latex 20% Shuangfei powder 76%

[0012] Head Example 2:

[0013] Confetti 8% White latex 15% Light calcium powder 40% Talcum powder 37%

Embodiment 3

[0015] Confetti 3% White latex 13%

[0016] Shuangfei powder 25%, light calcium powder 25%, talcum powder 34%

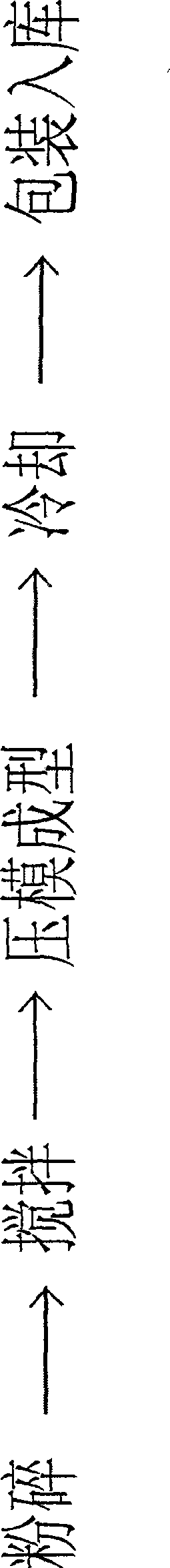

Embodiment 4

[0018] Confetti 6% White latex 25% Light calcium powder 69%

[0019] First, put the recovered paper (paper scraps) into a shredder driven by an 11kW motor and a speed of 1500 rpm, and crush them into cotton candy-like paper scraps. Then put the crushed paper scraps into the mixer, add 300-1000-mesh Shuangfei powder, light calcium powder or talcum powder, then add white latex and stir for 30 minutes until it becomes a paste-like pulp. After setting the required temperature and mold opening time on the mold opening machine, weigh the pulp and put it into the mold, then turn on the switch to press the mold. After the completion, take out the product, cool it, and finally pack it into the warehouse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com