Natural sweetener and methods of manufacturing thereof

A natural sweetener and flavor technology, applied in food preparation, function of food ingredients, confectionery industry, etc., can solve the problem of increasing the extra cost of manufacturing methods, limiting applications, and adverse sensory characteristics such as flavor, smell, taste, and color, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Commercially available heat-processed mogroside powder was analyzed to determine its original, unmodified composition. Mormordica 80% (Amax NutraSource, California), PureLo (Bio Vittoria, New Zealand), and ACT (Hamburg, Germany) were tested to determine insoluble content, color, phenolic content, and flavor / odor volatile content .

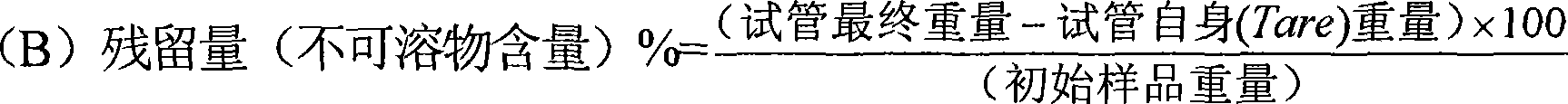

[0039] The insoluble content was determined by gravimetric analysis. Weigh about 100 mg of mogroside sample into a tared test tube. Add about 5 ml of room temperature water and mix the contents well. Centrifuge the sample in a low-speed benchtop centrifuge, then discard the supernatant. The tube was inverted and the neck of the tube was carefully dried by wiping with tissue paper. The tubes were then placed under high vacuum overnight to remove residual moisture. The test tube containing the dried sample is then weighed. The insoluble matter content or residual amount is calculated with formula B:

[0040] Total phenol content was det...

Embodiment 2

[0046] The unmodified AMAX commercial thermally processed extract in Example 1 was further analyzed using the methods provided in Example 1 to determine the concentration of various flavor / odor volatile components. Analysis of samples for the determination of aldehydes (hexanal, heptanal, octanal, nonanal and decanal), unsaturated aldehydes (octenal, undecenal, 1-decadienal, 2-decadienal), Methyl ketones (2-heptanone and 2-undecanone), and butyl crotonate content. The results are shown in Table 2 below.

[0047] Table 2: Flavor / Odor Volatile Components in Unmodified AMAX

Embodiment 3

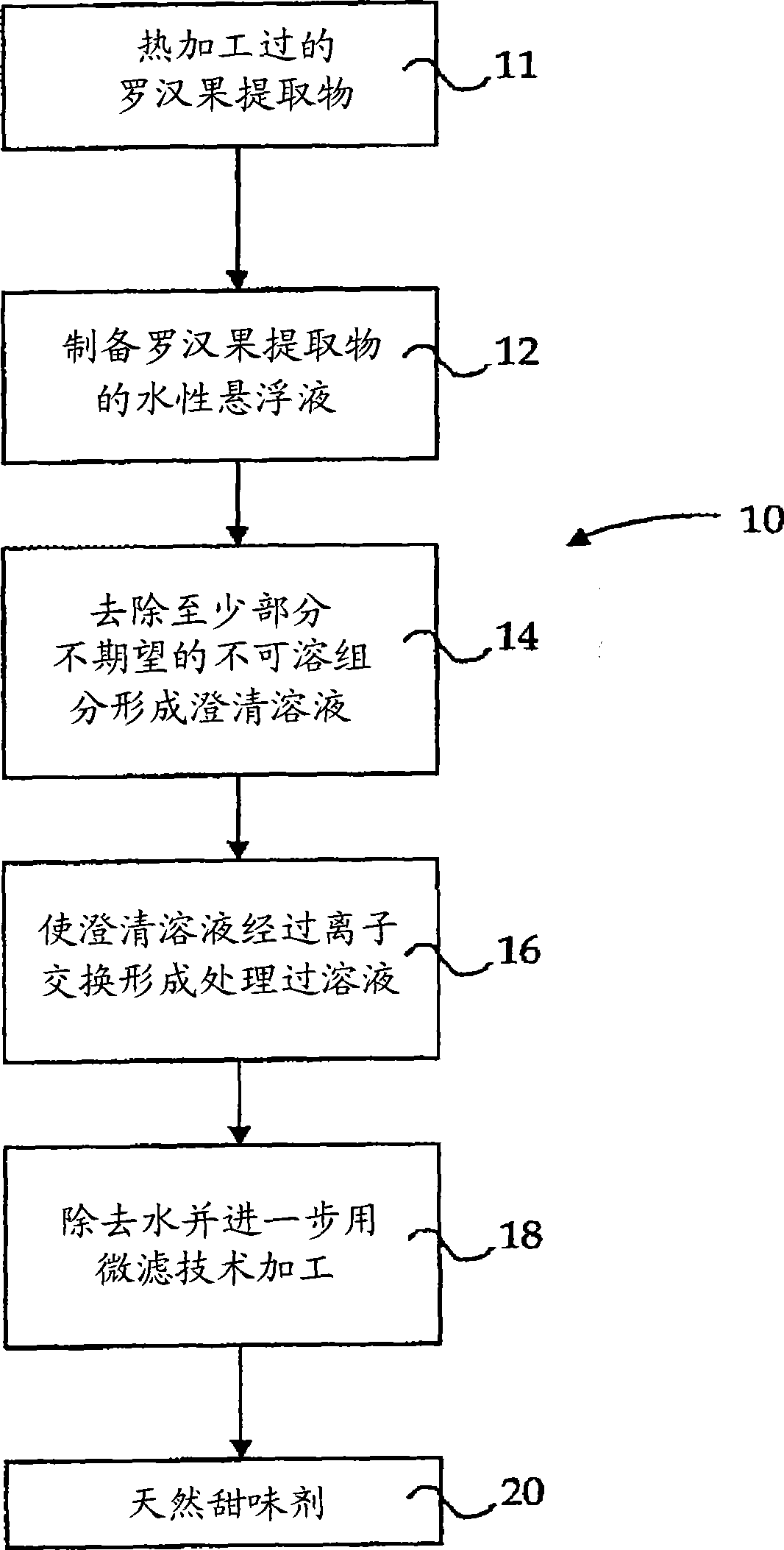

[0049] The unmodified AMAX Luo Han Guo extract in Example 1 was further processed and concentrated using the methods disclosed herein to remove undesired organoleptic properties.

[0050] About 50 grams of unmodified AMAX extract was suspended in room temperature water (about 25°C) to form an aqueous suspension or slurry with about 2% solids. The aqueous suspension was then vacuum filtered at room temperature using Whatman #2 filter paper (Whatman Corporation, Florham Park, NJ) to remove water insoluble components to form a clear filtrate or a clear aqueous solution. The clarified filtrate was then passed through an Amberlite TM Resin (Rohm & Haas, Philadelphia, Pennsylvania) and operated at room temperature to form a treated aqueous solution. The treated aqueous solution was then processed through an ultrafiltration membrane with a MWCO (Pall Corporation, East Hills, New York) of 1,000 Daltons at room temperature under a pressure of 50 psig to form a treated Monk Fruit extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com