Precursor water solution for preparing CaCu3Ti4O12 and preparing method thereof

A technology of calcium copper titanate, citric acid aqueous solution, applied in chemical instruments and methods, inert gas compounds, inorganic chemistry and other directions, can solve the problems of not meeting economic requirements, low utilization rate of raw materials, etc., and achieves low preparation cost and raw materials. The effect of high utilization and easy post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

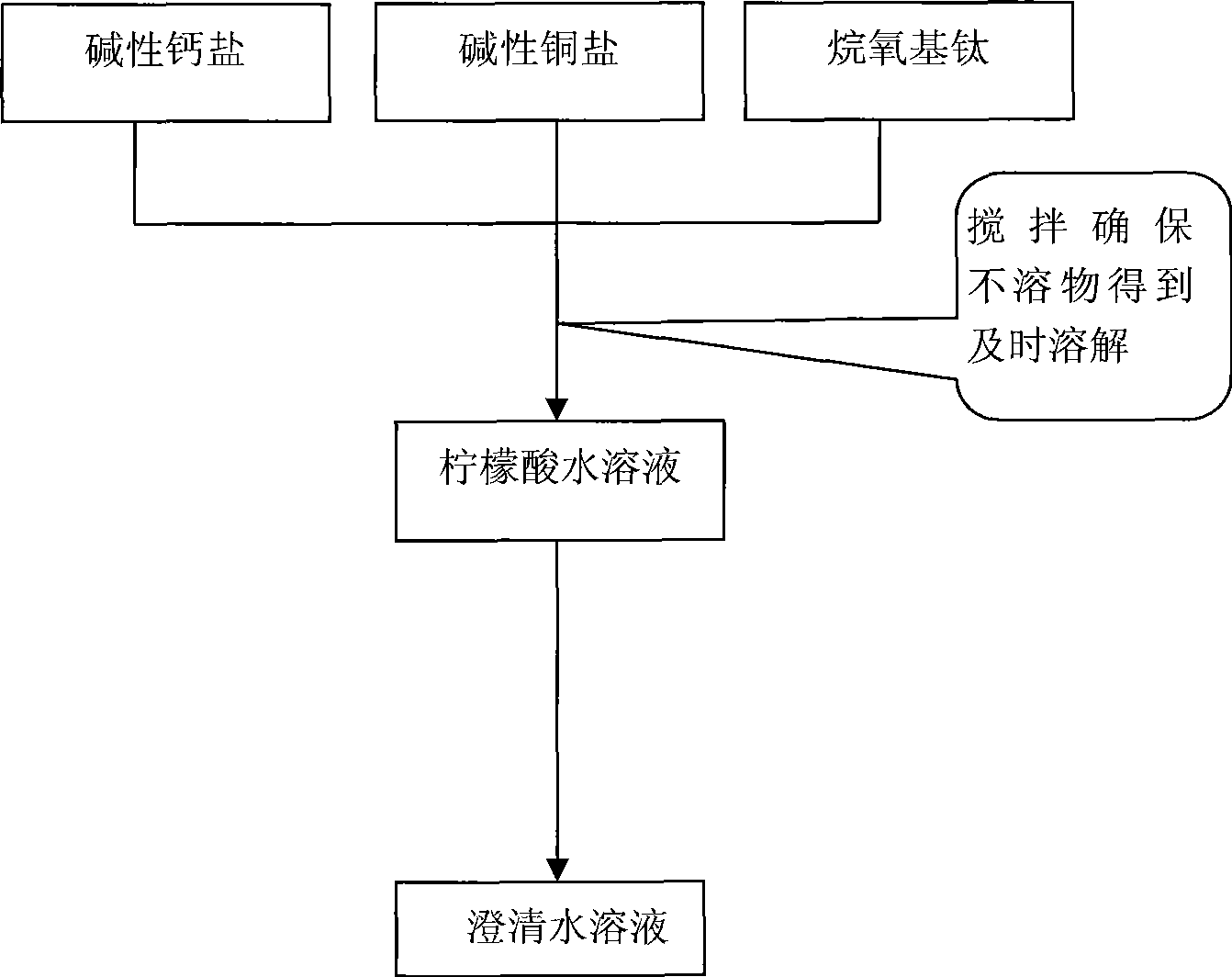

[0034] Weigh 12.600g of citric acid monohydrate and dissolve in 60ml of deionized water to obtain a clear and transparent solution. Weigh 1.113gCa(OH) 2 , while maintaining vigorous stirring, the Ca(OH) 2 Added to the prepared aqueous citric acid solution to obtain a clear and transparent solution.

[0035] Weigh 4.390g Cu(OH) 2 , under the condition of maintaining vigorous stirring, the Cu(OH) 2 Slowly add dissolved Ca(OH) 2 Aqueous solution of citric acid to obtain blue transparent solution A 1 .

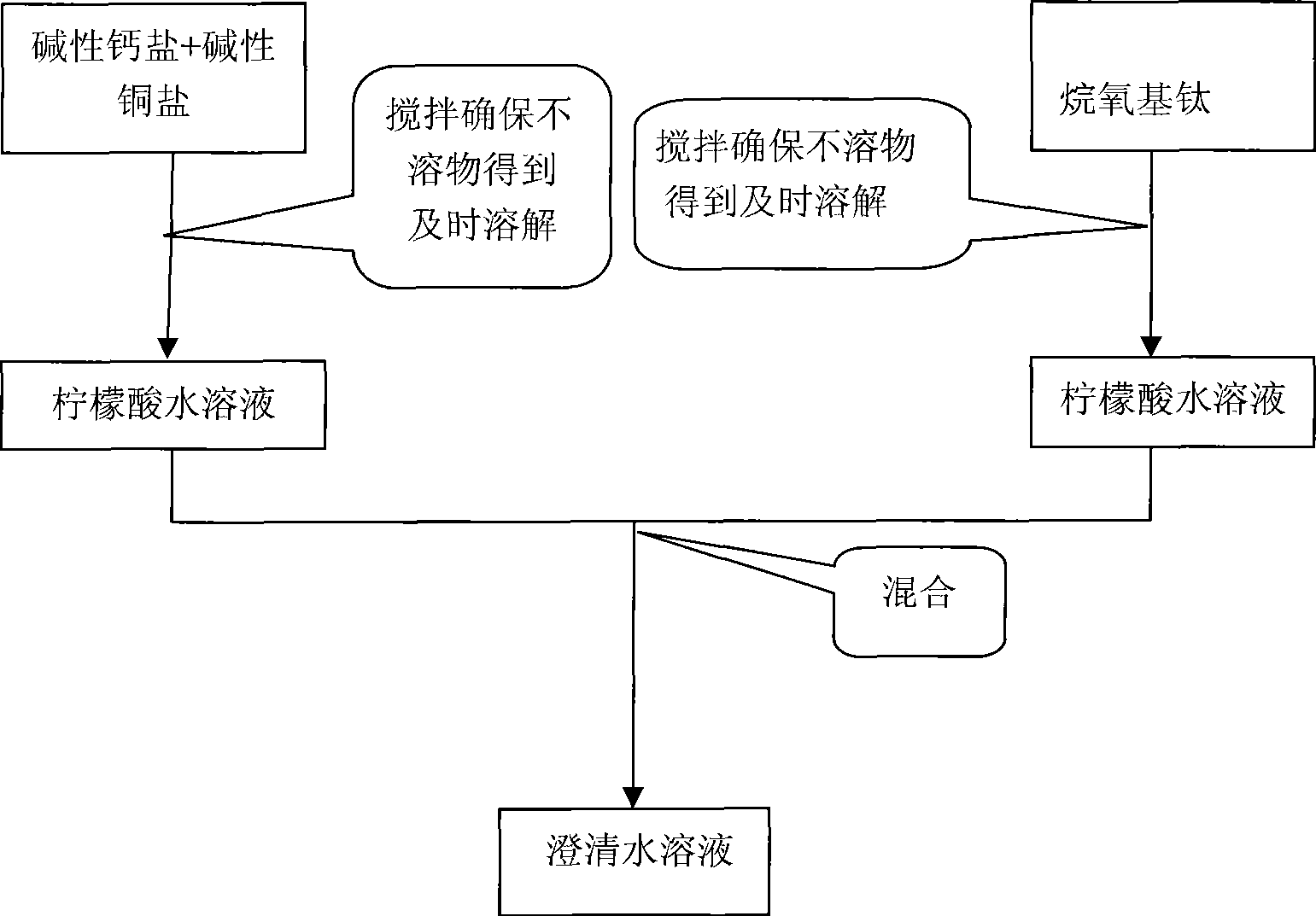

[0036] Weigh 25.216g of citric acid monohydrate and dissolve in 100ml of deionized water to obtain a clear and transparent solution. Weigh 20.470 g of n-butoxytitanium, and slowly add n-butoxytitanium dropwise into the citric acid aqueous solution under the condition of maintaining vigorous stirring. After the dropwise addition, continue to stir vigorously to obtain a yellow clear solution B 1 .

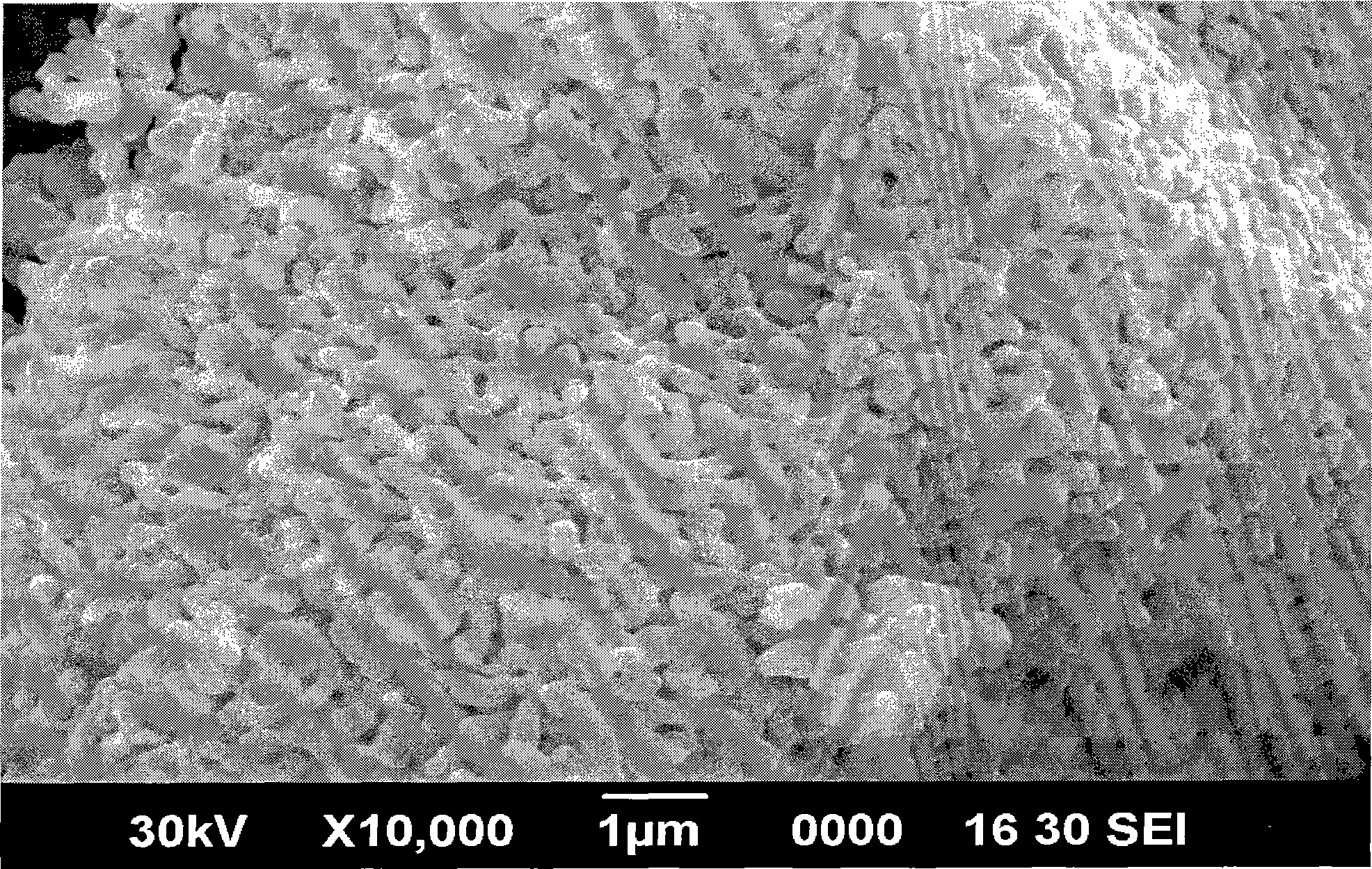

[0037] A will be produced 1 Solution and B 1 The solutions are mixed unde...

Embodiment 2

[0040] Weigh 12.600g of citric acid monohydrate and dissolve in 60ml of deionized water to obtain a clear and transparent solution. Weigh 0.840 g of ground CaO, and add CaO to the prepared citric acid aqueous solution under the condition of maintaining vigorous stirring to obtain a clear and transparent solution.

[0041] Weigh 4.390g Cu(OH) 2 , under the condition of maintaining vigorous stirring, the Cu(OH) 2 Slowly add CaO-dissolved citric acid aqueous solution to obtain blue transparent solution A 2 .

[0042] Weigh 25.216g of citric acid monohydrate and dissolve in 100ml of deionized water to obtain a clear and transparent solution. Weigh 20.420 g of n-butoxytitanium, and slowly add n-butyl titanate dropwise into the aqueous citric acid solution under the condition of maintaining vigorous stirring. After the dropwise addition, continue to stir vigorously to obtain a yellow clear solution B 2 .

[0043] A will be produced 2 Solution and B 2 The solutions are mixed ...

Embodiment 3

[0046] Weigh 2.102g of citric acid monohydrate and dissolve in 20ml of deionized water to obtain a clear and transparent solution. Weigh 0.371gCa(OH) 2 , under the condition of maintaining vigorous stirring, the Ca(OH) 2 Add to the prepared aqueous solution of citric acid to obtain a clear and transparent solution.

[0047] Weigh 1.463g Cu(OH) 2 , under the condition of maintaining vigorous stirring, the Cu(OH) 2 Slowly add dissolved Ca(OH) 2 Aqueous citric acid solution, the final blue transparent solution A 3 .

[0048] Weigh 3.510 g of citric acid monohydrate and dissolve in 20 ml of deionized water to obtain a clear and transparent solution. Weigh 6.806g of n-butoxytitanium, and slowly add n-butoxytitanium into the citric acid aqueous solution dropwise under the condition of maintaining vigorous stirring. After the dropwise addition, continue to stir vigorously, and finally obtain a yellow clear solution B 3 .

[0049] A will be produced 3 Solution and B 3 The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com