New types of compatibilising agents for improving the storage stability of polyol mixtures

A technology of polyol composition and compatibilizer, applied in the field of homogeneous polyol mixture and foam preparation, can solve the problems such as loss of homogeneity, incompatibility, and inability to use the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

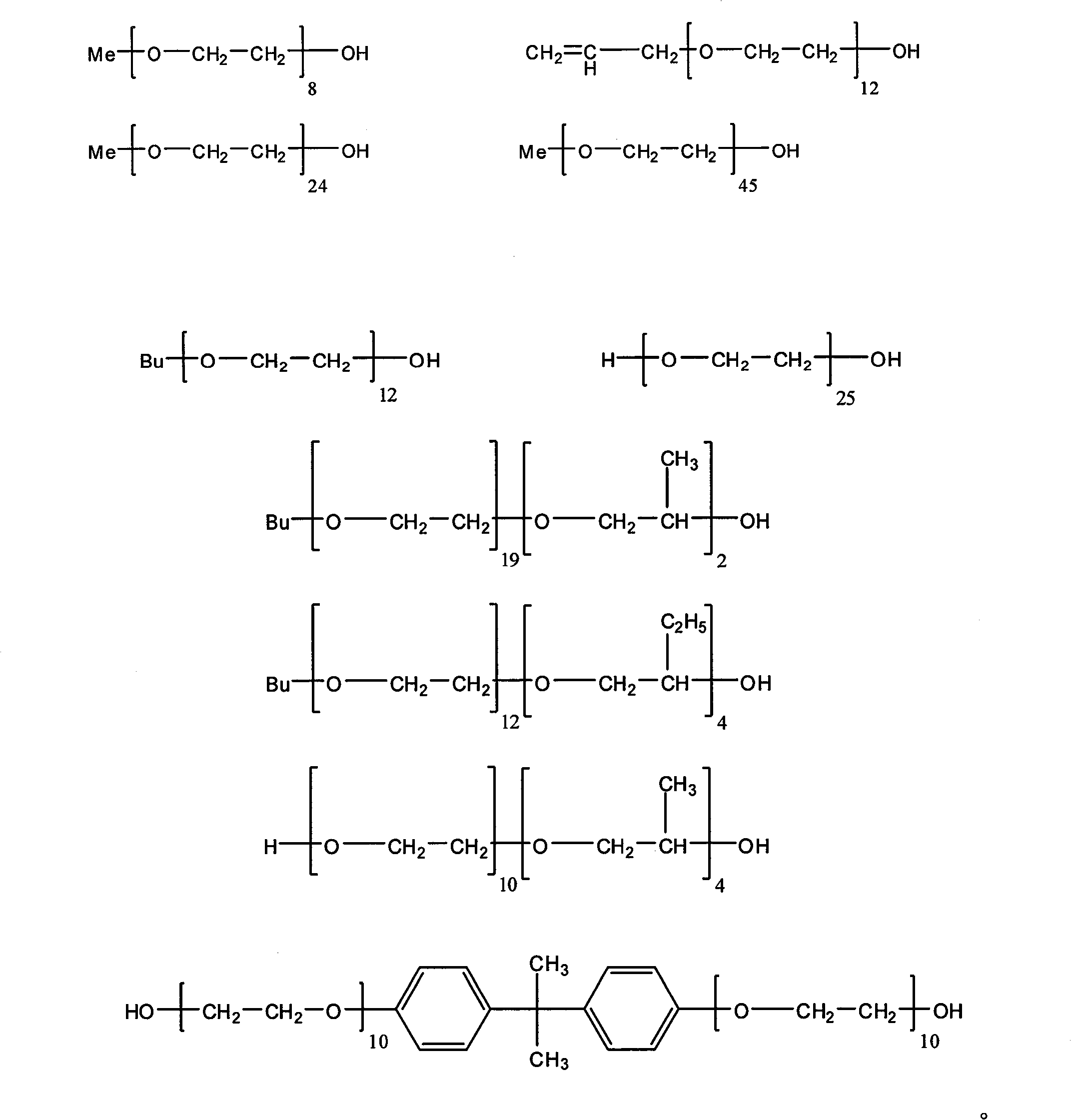

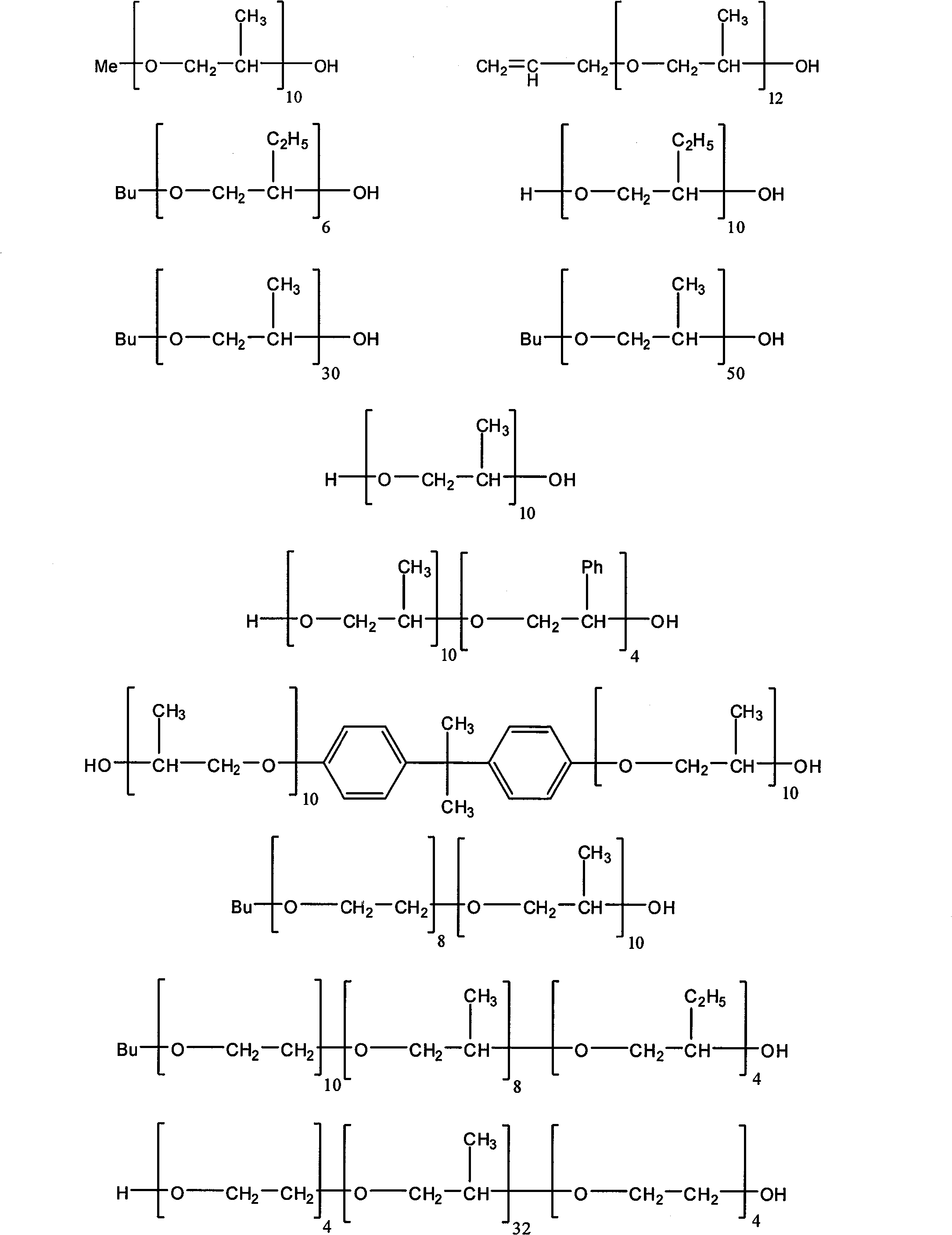

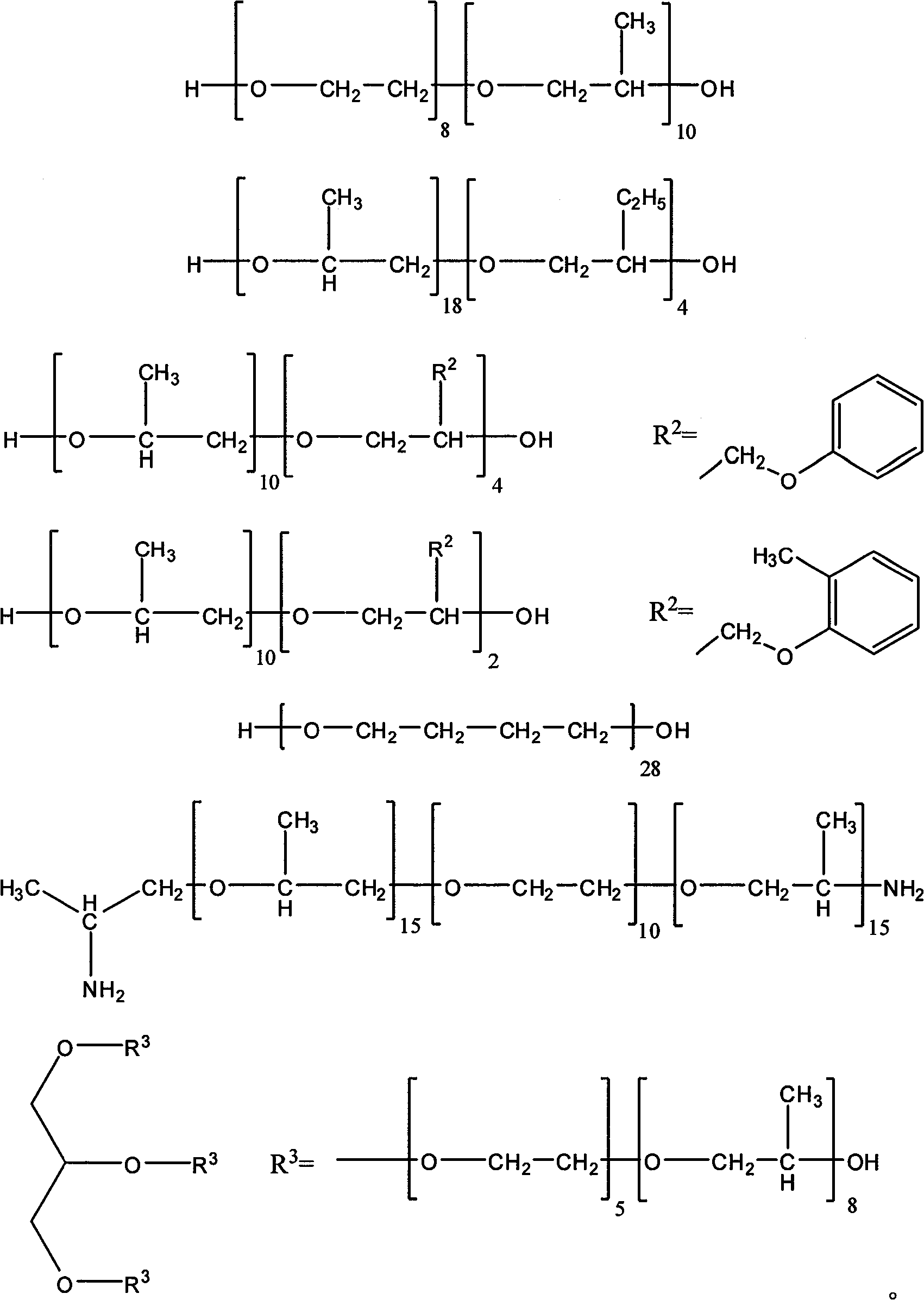

Method used

Image

Examples

Embodiment 1

[0140] 28 g of hydrophobic polyether monohydric alcohol (butanol starting, M = about 1800 g / mol, w (EO) = 0%) and 36 g of hydrophobic polyether diol (M = about %) and 24 g of hydrophilic polyether monoalcohol (starting from methanol, M=about 1100 g / mol, w(EO)=100%) were mixed, and 13 g of Desmodur N 3200 (technical grade trifunctionalized from Bayer AG) were added isocyanates). Then 100 g of propylene carbonate were added. The mixture was heated to 100°C and then mixed with 0.1 g Tegokat 722 (dicaprylate) (available from TIB Mannheim). The mixture was stirred for a further 4 hours at this temperature.

Embodiment 2

[0142] 26 g of hydrophobic polyether monohydric alcohol (butanol starting, M = about 1800 g / mol, w (EO) = 0%) and 34 g of hydrophobic polyether diol (M = about 2200 g / mol, w (EO) = 10 %), 15 g of hydrophilic polyether monool (starting from methanol, M=about 1100 g / mol, w(EO)=100%) and 14 g of hydrophilic polyether monool (M=2000 g / mol, w(EO) = 100%) were mixed and 12 g of Desmodur N 3200 (technical grade trifunctional isocyanate from Bayer AG) were added. Then 100 g of propylene carbonate were added. The mixture was heated to 100°C and then mixed with 0.1 g Tegokat 722 (dioctanoate) (available from TIB Mannheim). The mixture was stirred for a further 4 hours at this temperature.

Embodiment 3

[0144] 34 g of hydrophobic polyether monohydric alcohol (butanol starting, M = about 1800 g / mol, w (EO) = 0%) and 30 g of hydrophobic polyether diol (M = about %) and 25 g of hydrophilic polyether monool (starting from methanol, M=2000 g / mol, w(EO)=100%) were mixed, and 11 g of Desmodur N 3200 (a technical grade trifunctional isocyanate obtained from Bayer AG) was added ). Then 100 g of propylene carbonate were added. The mixture was heated to 100° C. and finally mixed with 0.1 g Tegokat 722 (dicaprylate) (available from TIB Mannheim). The mixture was stirred for a further 4 hours at this temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com