Oxygen concentration detecting instrument

A technology of oxygen concentration and detector, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of temperature change sensitivity and high cost of single-mode diode laser, and achieve the effect of improving stability, reducing stability requirements, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

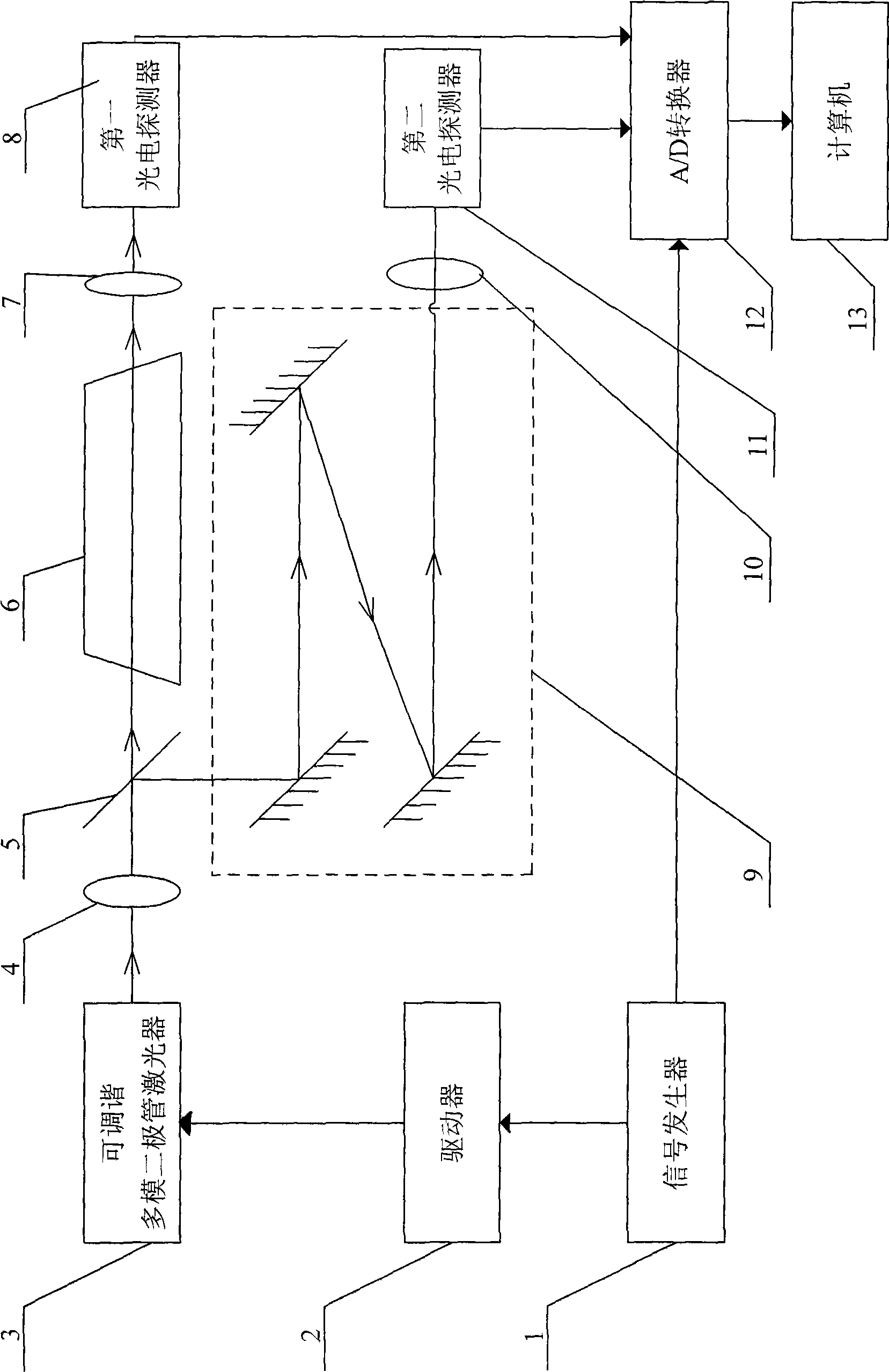

[0009] Specific implementation mode one: the following combination figure 1 Describe this embodiment, this embodiment consists of a signal generator 1, a driver 2, a tunable multimode diode laser 3, a collimator lens 4, a beam splitter 5, a sample cell 6, a first focusing lens 7, and a first photodetector 8 , mirror group 9, second focusing lens 10, second photodetector 11, A / D converter 12 and computer 13, an output end of signal generator 1 is connected to the input end of driver 2, and the output end of driver 2 Connect the input end of the tunable multimode diode laser 3, the output light of the tunable multimode diode laser 3 is incident into the collimator lens 4, and is transmitted through the collimator lens 4 to obtain parallel light, and the parallel light is divided into transmission by the beam splitter 5 Light and reflected light, the transmitted light enters the first focusing lens 7 after passing through the sample cell 6, and is incident on the optical signal i...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the reflector group 9 is composed of a plurality of reflectors, and the light incident on the reflector group 9 is incident on the second reflector after being reflected by each reflector. Focusing lens 10. Other composition and connection methods are the same as those in Embodiment 1.

[0013] The function of the mirror group 9 is to allow the reference light to pass through a longer absorption path in a limited space, so as to improve the signal-to-noise ratio of the reference signal, thereby improving the measurement accuracy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com