Horizontal omnidirectional planar printed antenna

A printing antenna and planar technology, which is applied in the direction of antenna, slot antenna, radiation element structure, etc., can solve difficult problems and achieve the effects of low out-of-roundness, compact antenna structure, and simplified antenna design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The structure of the horizontal omnidirectional planar printed antenna is as follows Figure 1~3 As shown, it includes slot array, printed circuit board, stripline transmission line feed network.

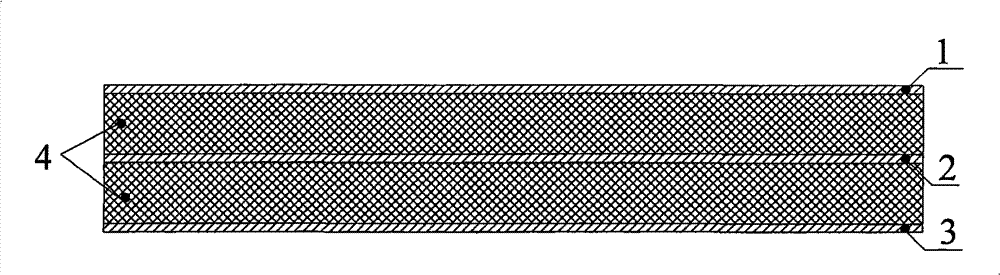

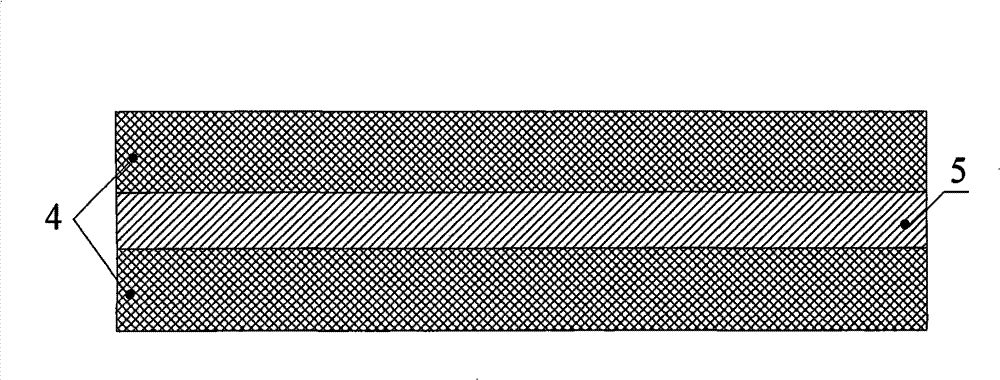

[0028] The stripline transmission line feed network is composed of metal ground layers 1, 3, feed layer 2, and dielectric layer 4, which realizes uniform feed and impedance matching of the antenna slot array, such as figure 1 shown. The feed layer 2 contains a metal conduction strip 5, such as figure 2 shown.

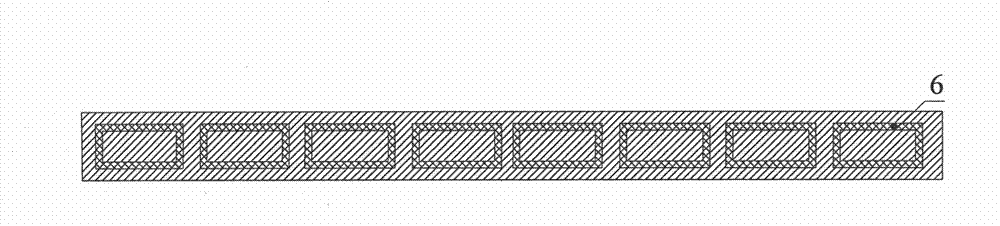

[0029] The slot array is composed of one or more sets of slot units 6. Taking 8 sets of slot units as an example, the slot units are printed on the upper and lower layers of metal layers 1 and 3 on the PCB, such as image 3 shown.

[0030] Through numerical simulation calculation and antenna test, the working frequency band of the horizontal omnidirectional planar printed antenna extends from 5.66GHz to 5.94GHz, and the bandwidth reaches 4.7%. At a working freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com