Method for producing carbon nano-tube film, carbon nano-tube film with laminated structure, anode, organic LED and carbon nano-tube element

A carbon nanotube film and carbon nanotube technology, applied in the direction of carbon nanotubes, single-walled carbon nanotubes, nanocarbons, etc., can solve problems such as increasing the sheet resistance of CNT films, affecting device properties, and destroying CNTs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] The following three types of CNTs were used to prepare transparent conductive films for comparative study:

[0148] Laser nanotube (L-CNT) (see (1) Guo, T.; Nikolaev, P.; Thess, A.; Colbert, D.T.; Smalley, R.E.Chem.Phys.Lett.1995, 243, 49.(2) Thess, A.; Lee, R.; Nikolaev, P.; Dai, H.; Petit, P.; Robert, J.; .; Fisher, L.E.; Smalley, R.E. Science 1996, 273, 483.),

[0149] Arc discharge nanotubes (P-CNT, P3 nanotubes from Carbon Solutions Inc.), and

[0150] HiPCO nanotubes (H-CNTs, Carbon Nanotechnology Inc.).

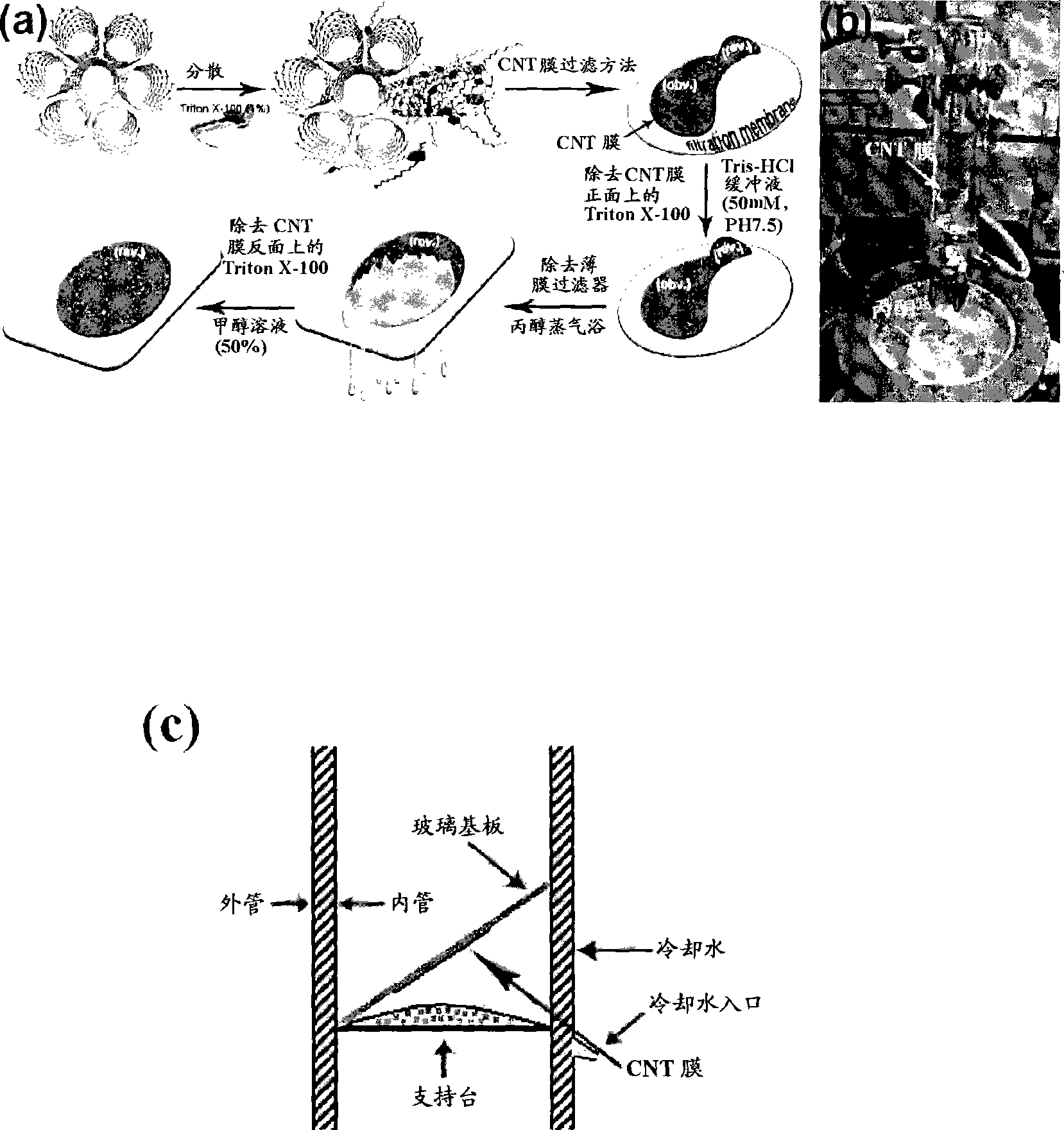

[0151] Based on Wu et al. (see Wu, Z.C.; Chen, Z.H.; Du, X.; Logan, J.M.; Sippel, J.; Nikolou, M.; Kamaras, K.; Reynolds, J.R.; Tanner, D.B.; Hebard, A.F.; Rinzler, A.G.Science 2004, 305, 1273) reported the procedure of the filtration method to prepare CNT membranes respectively.

[0152] The configuration of tris(hydroxymethyl)aminomethane hydrochloride (Tris-HCl) buffer is routine for those skilled in the art. For example, the configuration process of 50m...

Embodiment 2

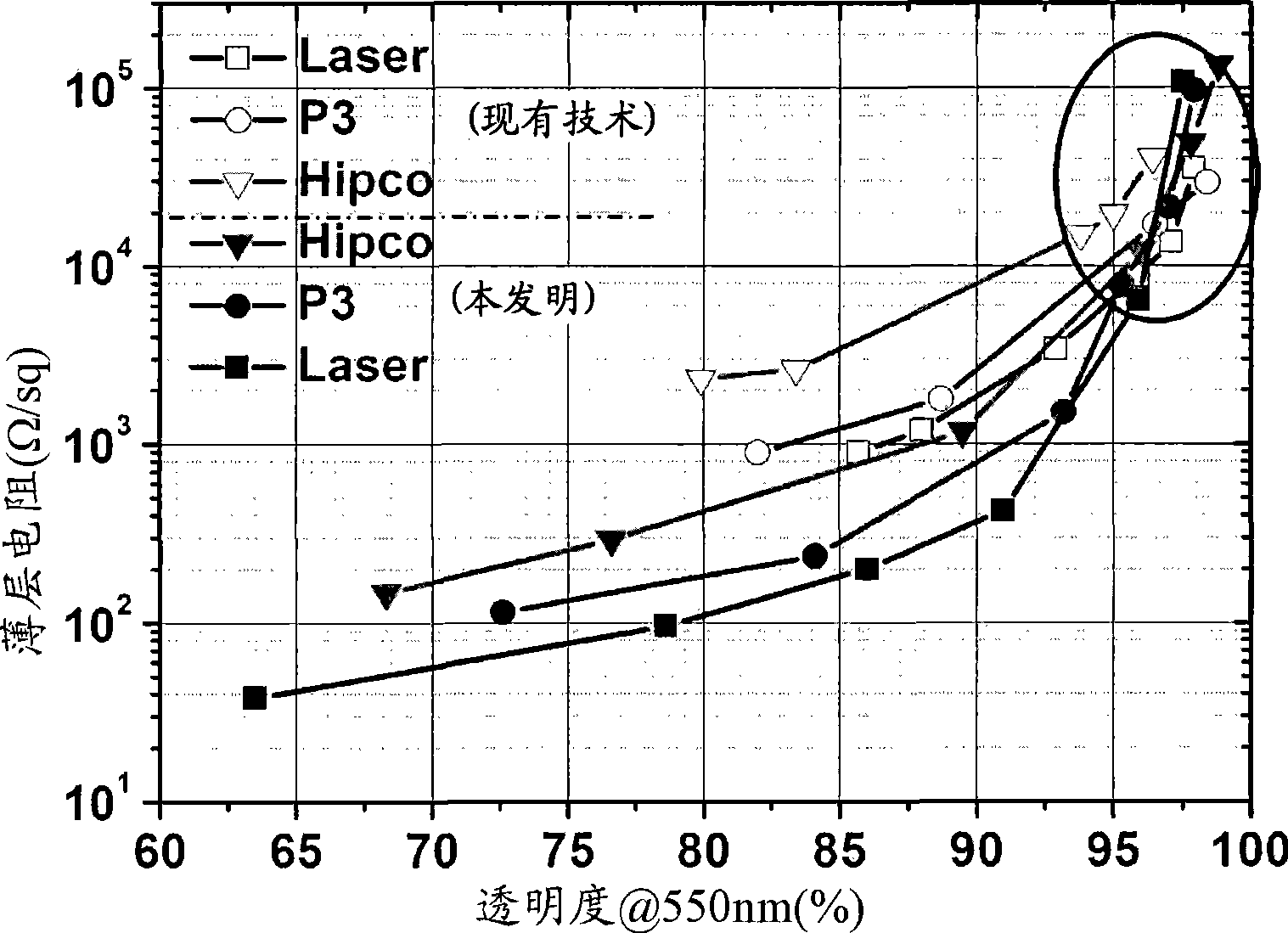

[0163] In order to check whether the above-mentioned resistance exists, the CNT film on the MCE is divided into four parts equally, and one part is processed in the way of the prior art, that is, its membrane filter is immersed in acetone for 48h; the acetone is renewed every 12 hours . The resistance of the film thus obtained was taken as the total resistance. After removing the other three membrane filters with the steam generator of the first aspect, the other three were further treated as follows: remove only Triton X-100 on the front side of the membrane; remove only Triton X-100 on the reverse side of the membrane; And remove the Triton X-100 (as the essential CNT film) on both sides. The results show that the resistance of the CNT film with the essence of 78% transparency is 46% of the total resistance ( Figure 4 illustration in ). and, Figure 4 The variation of the intrinsic CNT film with transparency is shown. As the transparency increased from 62% to 96%, the ...

Embodiment 3

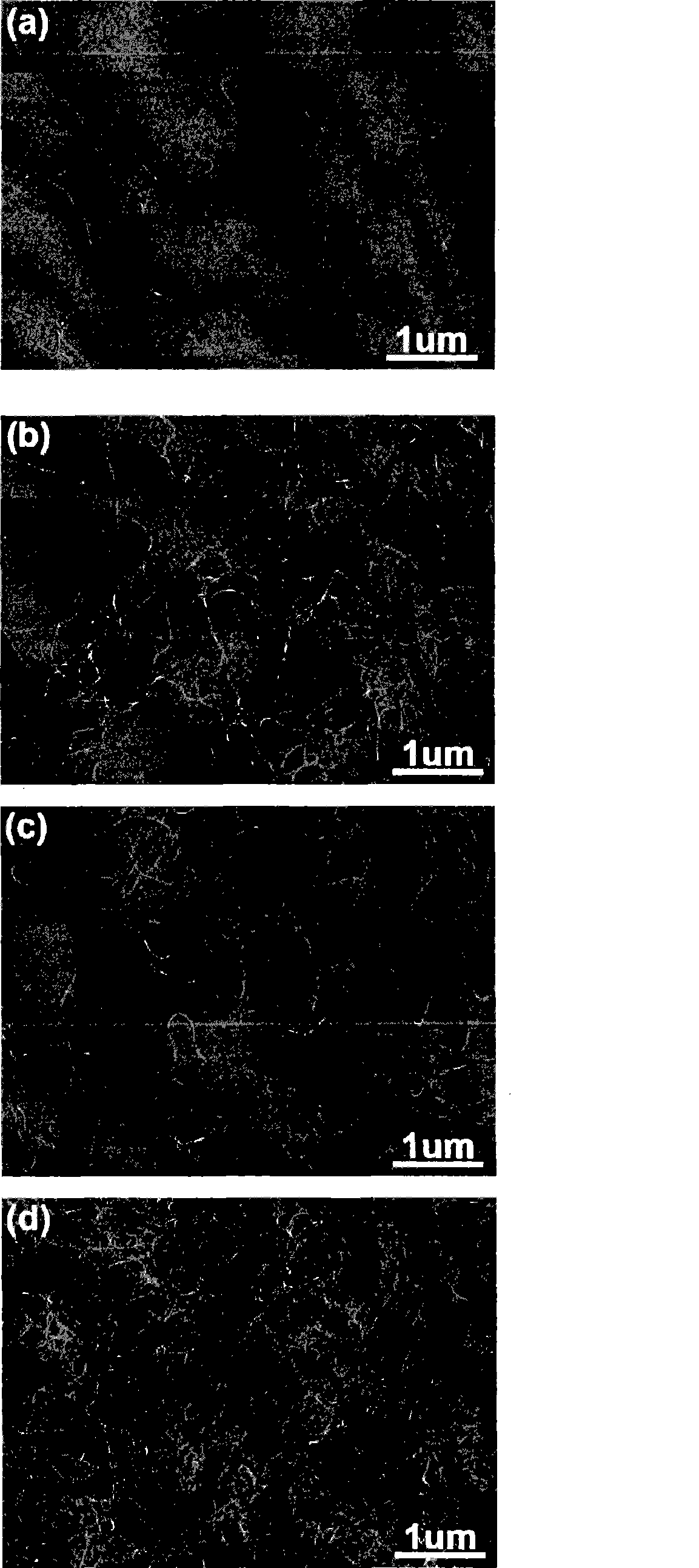

[0167] For the conductivity of transparent CNT films, they are characterized by a dramatic increase of several orders of magnitude, which according to the percolation theory is attributed to the typical phenomenon of electro-osmosis with respect to the formation of a network of conducting particles ((a) Pike, G.E.; Seager , C.phys.Rev.B 1974, 10, 1421.(b) Balberg, I.; Binenbaum, N.; Wagner, N.Phys.Rev.Lett.1984, 52, 1465.(c) Vigolo, B. ; Coulon, C.; Maugey, M.; Zakri, C.; Poulin, P. Science 2005, 309, 920).

[0168] Percolation is a statistical geometric theory that establishes a general law of exponents in power-law dependencies of geometric parameters. The percolation behavior of CNT networks has been reported by many research groups (cf. (a) Hu, L.; Hecht, D.S.; Grüner, G. Nano lett. 2004, 4, 2513. (b) Unalan, H.E.; Fanchini, G. .; Kanwal, A.; Pasquier, A.D.; Chhowalla, M. Nano lett. 2006, 6, 677.). In common terms, for CNT films just above the percolation threshold, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com