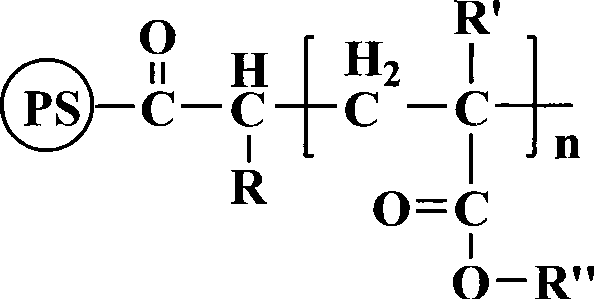

Method for graft modification for polystyrene resin by using ATRP

A technology for polystyrene modification, which is applied in the field of graft modification of polystyrene resin using ATRP, which can solve the problems of high grafting rate and achieve the effect of high loading capacity, simple reaction steps and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 1g of 1.82mmol / g chloroacetylated PS, 0.180g of CuCl, 0.37mL of pentamethyldiethylenetriamine, 6mL of ethyl methacrylate and 8mL of toluene into a reactor equipped with magnetic stirring, and place under nitrogen protection Reaction at 100°C for 4h. The reaction yielded 2.437 g of dry polystyrene-graft-polyethyl methacrylate, and the resin graft weight gain rate was 142.5%. Using a mixed hydrolyzate of 1,4-dioxane and water (3:1, V / V), hydrolyze polystyrene-grafted-polyethylmethacrylate for 4 hours at 90°C to obtain 2.192 g of two Affinity polystyrene resin.

Embodiment 2

[0023] 1g3.44mmol / g chloroacetylated PS-DVB cross-linked microspheres, 0.255g CuCl, 0.116g CuCl 2, 0.50mL of pentamethyldiethylenetriamine, 8mL of methyl methacrylate and 8mL of toluene were added into a reactor equipped with magnetic stirring, and placed under nitrogen protection at 85°C for 6h. The reaction yielded 4.983g of dry polystyrene-graft-polymethyl methacrylate, and the resin graft weight gain rate was 398.3%. Use the mixed hydrolyzate of 1,4-dioxane and water (2:1, V / V) to hydrolyze polystyrene-graft-polymethyl methacrylate for 4 hours at 90°C to obtain 4.691 g of two Affinity polystyrene resin.

Embodiment 3

[0025] 1g4.65mmol / g bromoacetylated PS-DVB cross-linked microspheres, 0.354g CuCl, 0.161g CuCl 2 , 0.70mL of tetramethylethylenediamine, 12mL of methyl methacrylate and 10mL of toluene were added into a reactor equipped with magnetic stirring, and placed under nitrogen protection at 85°C for 10h. The reaction yielded 9.518g of dry polystyrene-graft-polymethyl methacrylate, and the resin graft weight gain rate was 851.7%. Use the mixed hydrolyzate of 1,4-dioxane and water (2:1, V / V) to hydrolyze polystyrene-graft-polymethyl methacrylate for 8 hours at 90°C to obtain 8.493 g of two Affinity polystyrene resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com