Wire rope load performance undamaged evaluating method

A wire rope and load technology, which is applied in the field of nondestructive evaluation of wire rope load performance, can solve the problems of fuzzy measurement of damage degree, appeasement of catastrophic threats, and impossible to effectively characterize the overall performance of wire rope components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

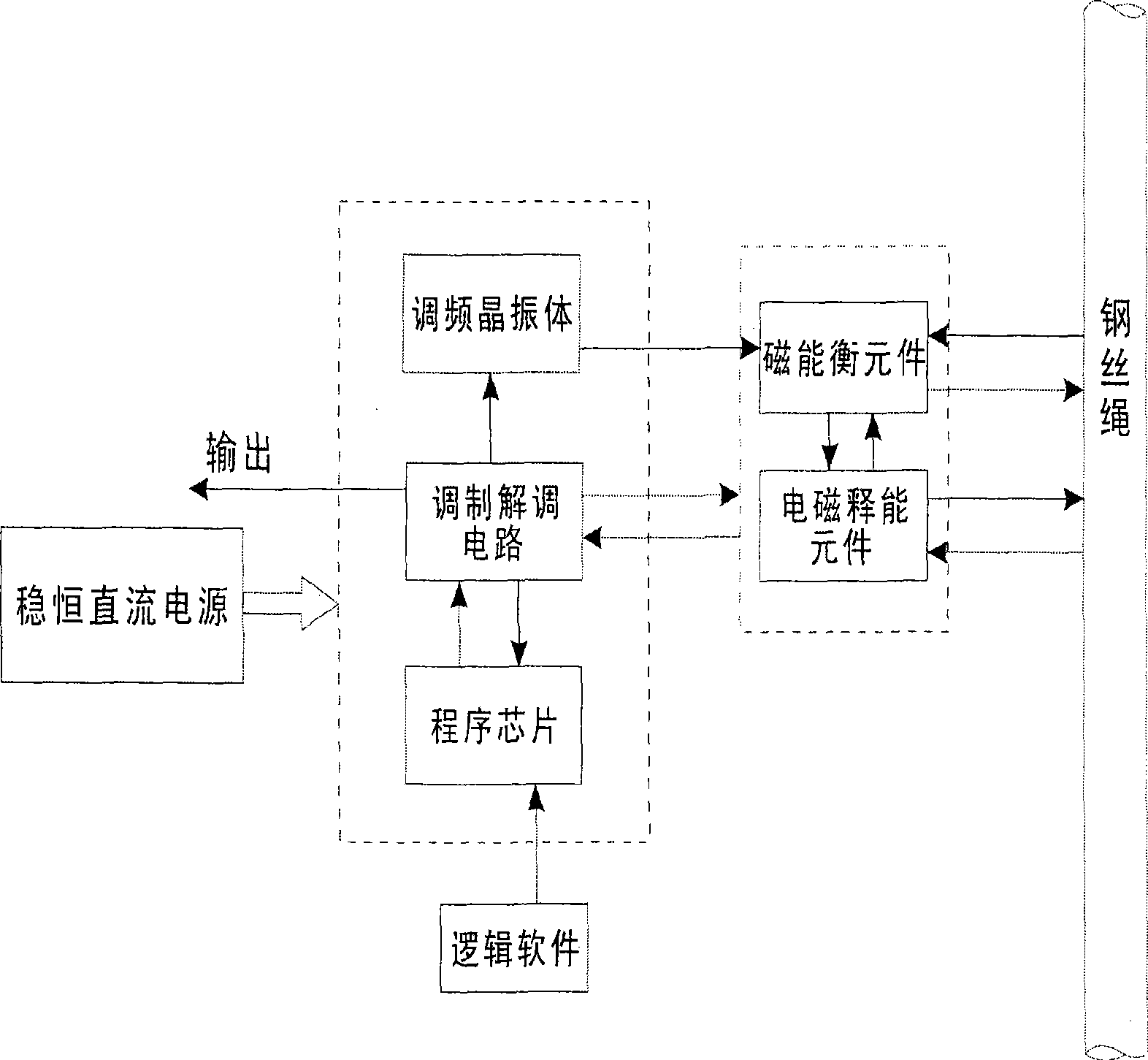

[0042] Utilizing the physical characteristics of the steel wire rope member load material, a relatively low magnetic field intensity H makes the steel wire rope member have a continuous and uniform small magnetic energy product (BH). The magnetic energy potential difference information discrimination technology (device) is used for real-time identification and extraction of the physical field change information of the load material that is equivalent to the single value equivalent of the mechanical performance degradation of the steel wire rope member such as bending, torsion, and tension. According to the mechanical calibration principle of the tensile load (breaking force) of steel wire rope components, an equivalent parameter is set up to represent the corresponding load performance change of steel wire rope components, and the state detection of each link of the steel wire rope component application cycle is completed in a non-destructive manner. Create a scientific evaluat...

Embodiment 2

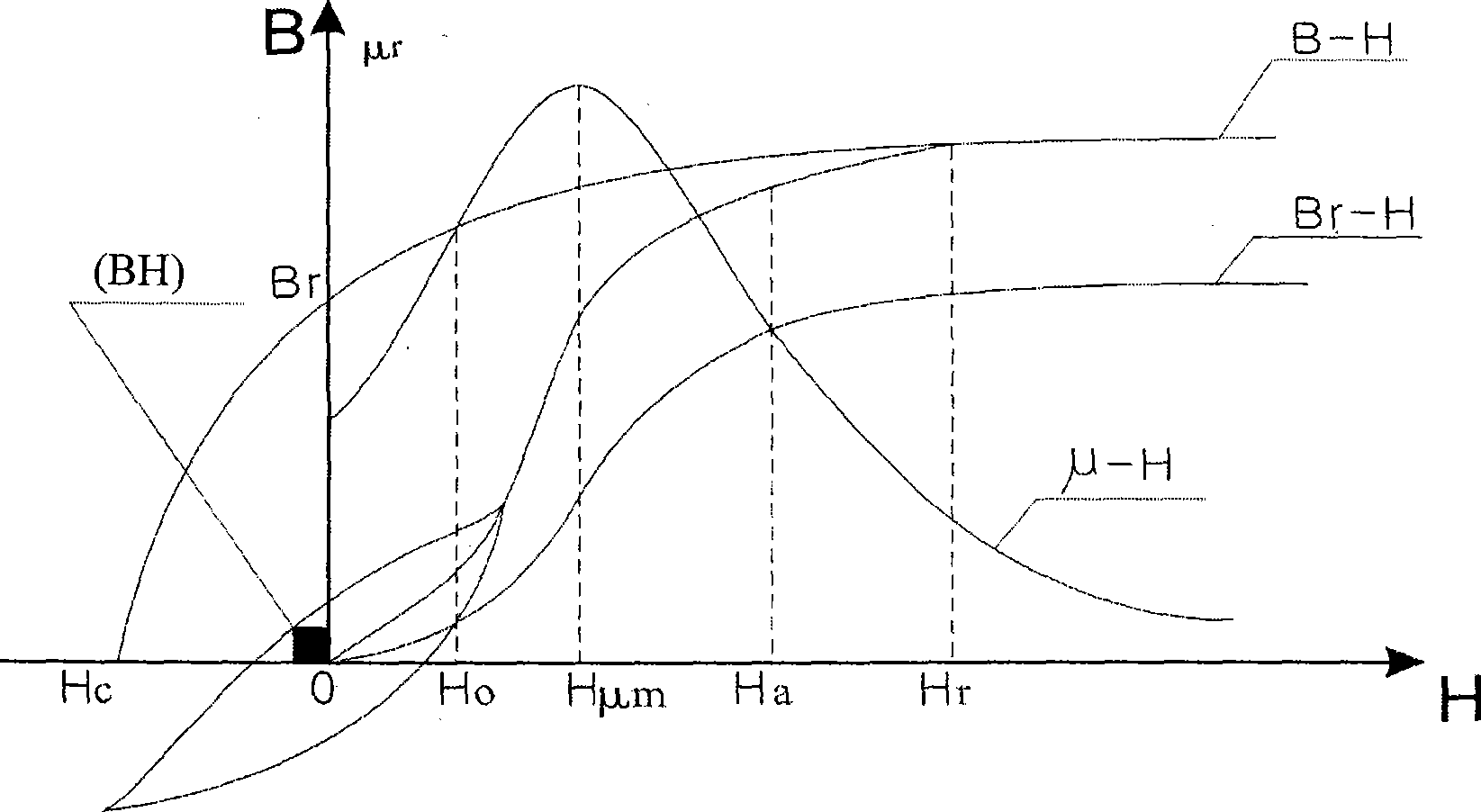

[0044] Utilizing the physical characteristics of the steel wire rope member load material, a relatively low magnetic field intensity H makes the steel wire rope member have a continuous and uniform small magnetic energy product (BH). Its characteristics are: the load material of the steel wire rope member is medium-high carbon steel or alloy steel, which has typical ferromagnetic properties. This physical characteristic can be used as "magnetic characteristic curve of iron and steel material" such as image 3 As shown, the B-H line is at H 0 ~H μm The rate of change in the interval is the highest, and the magnetic permeability of the material increases rapidly and reaches the maximum value, indicating that the magnetic properties (magnetic induction) of the material in this H interval are the most sensitive. Due to the hysteresis characteristics of ferromagnetic materials, any volume element dV of the steel wire rope component load material passing through the H field will ac...

Embodiment 3

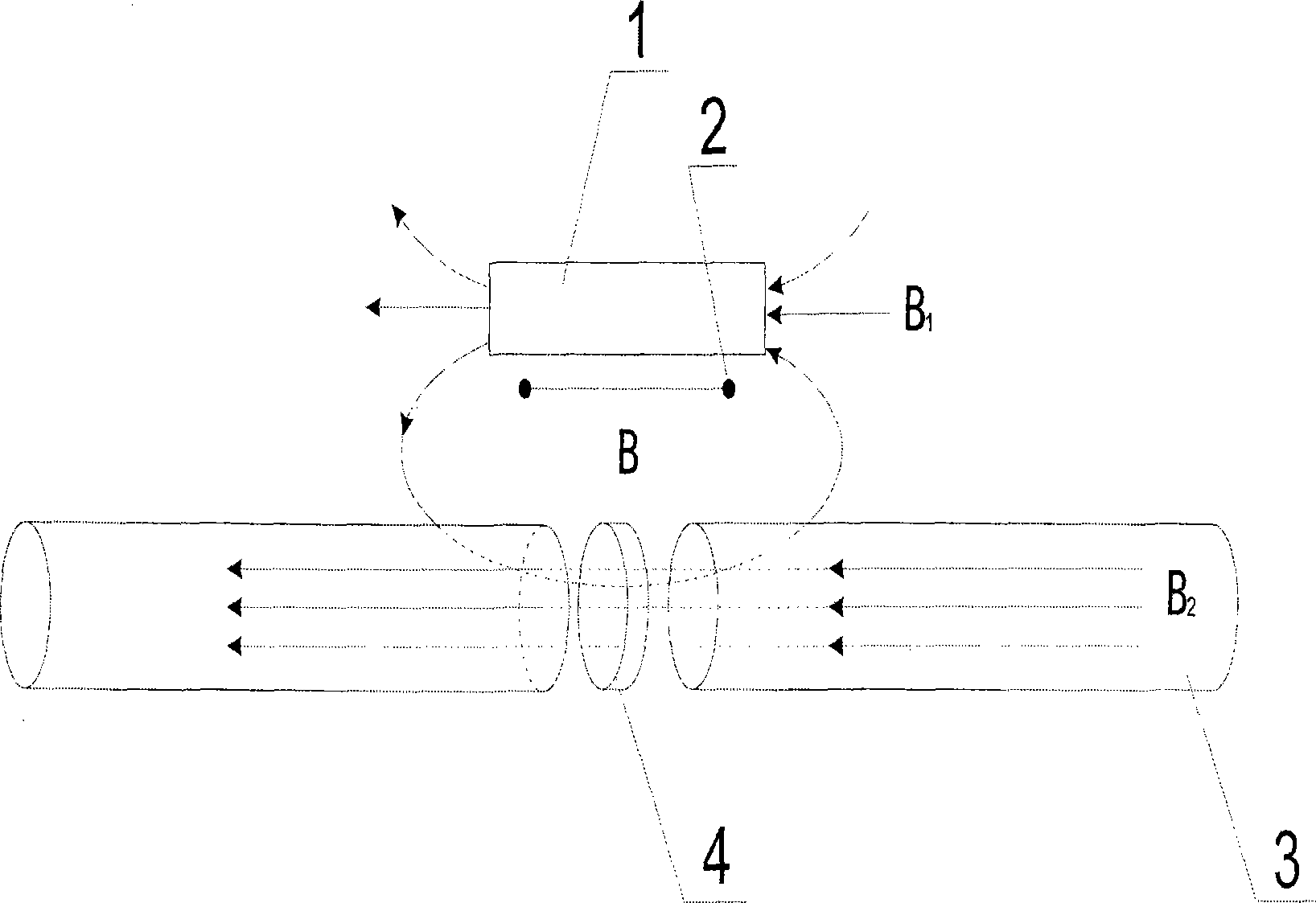

[0046] The physical field change information of the load material related to the single-value equivalent of the mechanical performance degradation of the steel wire rope member such as bending, torsion, and tension; it is characterized in that due to the ferromagnetic properties of the steel wire rope member load material, the member that is continuously applied with a magnetic load All ferromagnetic metal materials participating in the load work have an appropriate amount of low energy level (×1mT level) small magnetic energy product (BH), and if any volume element dV of the load material along its axial direction in the component is continuous, uniform and consistent , then the small magnetic energy product in any volume element dV is equal and evenly distributed, and the magnetic permeability μ of the adjacent volume element dV material is continuous and consistent, that is: the axial magnetic field established along the ferromagnetic material of the component The magnetic l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com