Method for producing medlin plastic substrate flexible silicon-based film solar battery integrated component

A technology of polyimide and silicon-based thin films, applied in the direction of electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of failure to achieve large-scale production, complex processing technology, high design, manufacturing, and maintenance costs problems, to achieve the effect of facilitating mass production, meeting social requirements, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

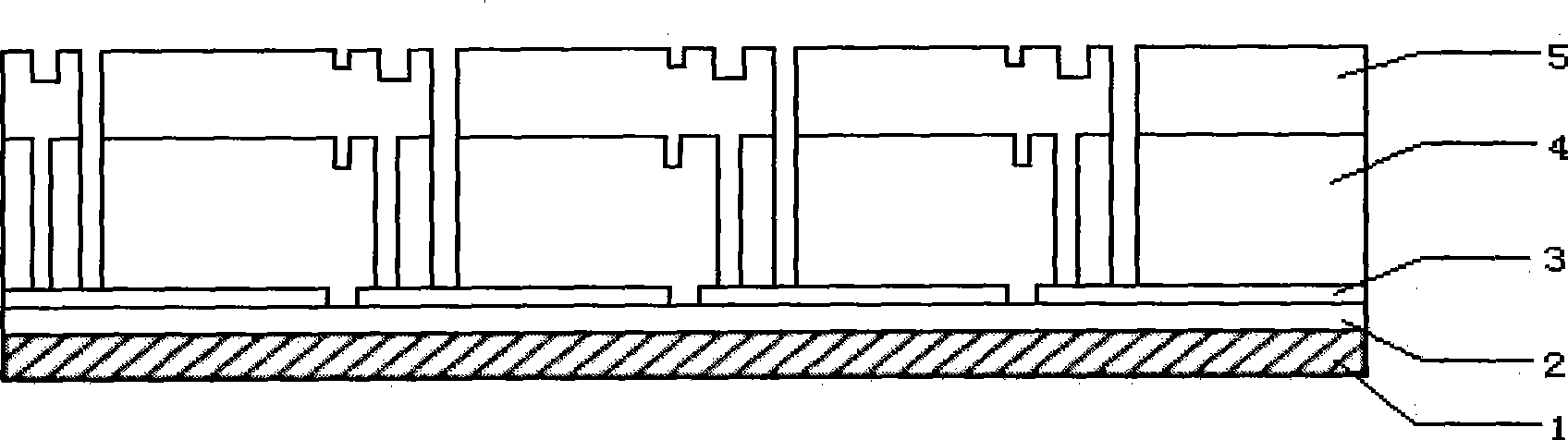

[0020] Squeegee-coat polyimide slurry on a common glass substrate, cure it at 80°C for 2 hours, and then raise it to 200°C for chemical imidization to form a polyimide film with a film thickness of 50 μm; on glass / The ZnO transparent conductive film was sputtered on the polyimide substrate, the substrate temperature was 150°C, and the film thickness was 800nm; silane was used as the reaction source gas, and the glow excitation frequency was 13.56MHz by radio frequency plasma enhanced chemical vapor deposition method, according to Glass-substrate silicon-based thin-film solar cell preparation process to prepare single-junction pin amorphous silicon thin-film solar cells: the p layer is a-SiC:B:H thin film with a film thickness of 10nm, the i layer is a-Si:H thin film, and the film layer The thickness is 300nm, the n layer is a-Si:P:H film, the thickness of the film layer is 30nm, and the substrate temperature is 175°C; the aluminum back electrode is evaporated by evaporation me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com