Sealing structure for processing reaction chamber by semiconductor

A technology of sealed structure and reaction chamber, which is applied in semiconductor/solid-state device manufacturing, pressure vessels used in chemical processes, metal material coating technology, etc., which can solve the problems of sealing ring corrosion, reduced life of sealing ring, and impossibility of complete contact, etc. Problems, to achieve the effect of prolonging life, prolonging path and increasing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

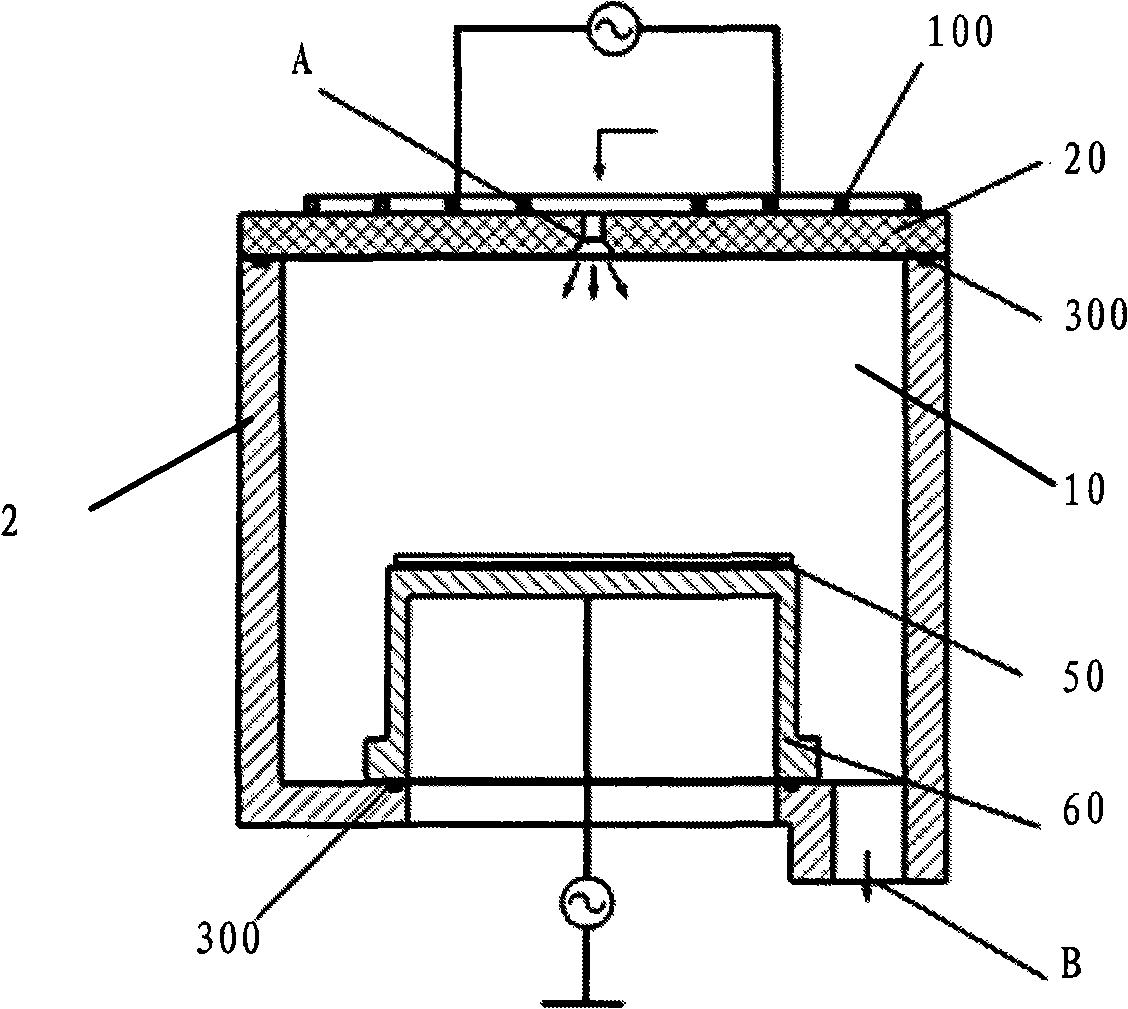

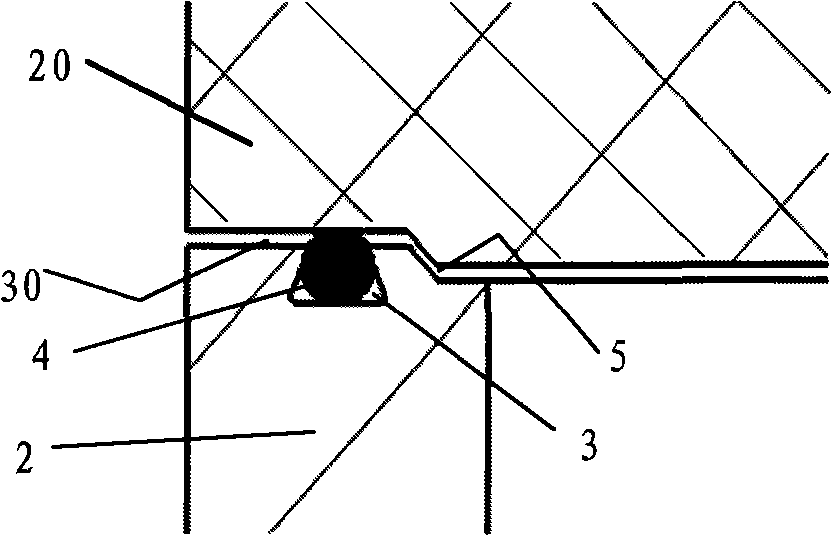

[0024] See 1 and Figure 3 ~ Figure 10 , Which shows a preferred embodiment of a sealing structure for a semiconductor processing reaction chamber of the present invention, including a cover plate 20, a chamber side wall 2 and an electrostatic chuck 60 which are connected to each other and form the reaction chamber 10 together. The connection 30 between the side wall 2 of the chamber and the cover plate 20 and / or the electrostatic chuck 60 is provided with a clamping member 3, usually preferably, at two connections 30 (the connection between the side wall 2 of the chamber and the cover plate 20) The location 30 and the connection location 30) between the side wall 2 of the chamber and the electrostatic chuck 60 are provided with a clamping member 3, which may be a structure that can be used to buckle and fix the sealing member in the prior art, such as a groove or The boss, in this embodiment, is preferably a trapezoidal groove. The clamping member 3 is provided with a sealing memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com