Sterilizing and enzyme-denaturing method of citrus fruit juice

A technology for citrus and fruit juices, which is applied in the field of ultra-high pressure sterilization and enzyme inactivation of citrus juices. It can solve problems such as changes in product color and flavor, unfavorable product sensory and freshness, and loss of nutrients, and achieve energy consumption without pollution. Operation Simple, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

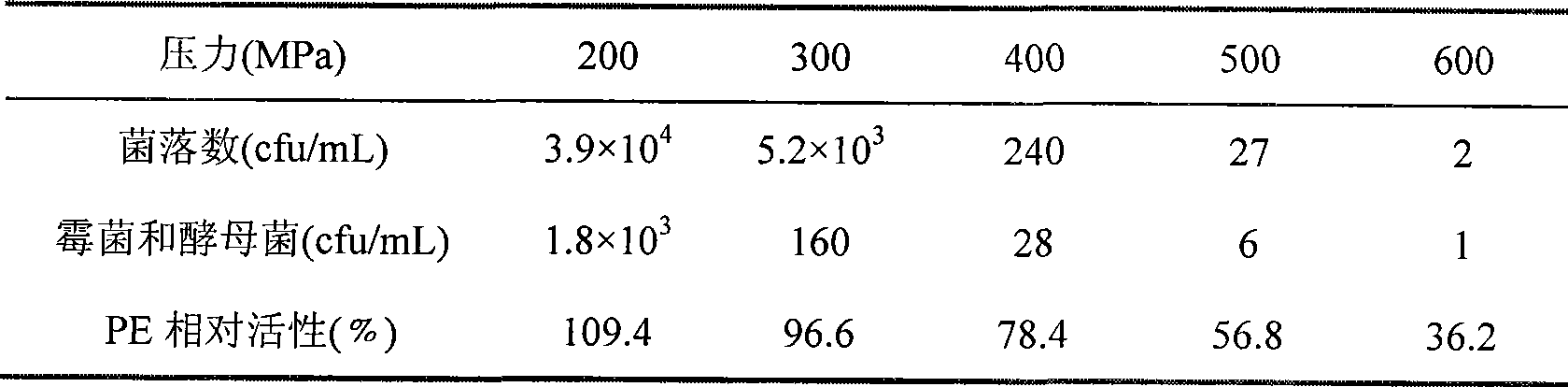

[0018] Select fresh pomelo, wash it, squeeze the juice and filter, blend, high-pressure homogenize and degass, then vacuum pack the pomelo juice. After testing, the initial number of colonies in grapefruit juice was 2.7×10 5 cfu / mL, the initial mold and yeast count was 1.2×10 4 cfu / mL. Heat the grapefruit juice to 25°C, put it into an ultra-high pressure container, pressurize it to 200MPa, 300MPa, 400MPa, 500MPa, and 600MPa at 25°C, and keep the pressure for 10 minutes; release the pressure, take out the sample, and dry the packaging surface moisture.

[0019] The relative activity of microorganisms and PE in grapefruit juice samples after sterilization and enzyme removal was detected, and the results are shown in the following table:

[0020]

Embodiment 2

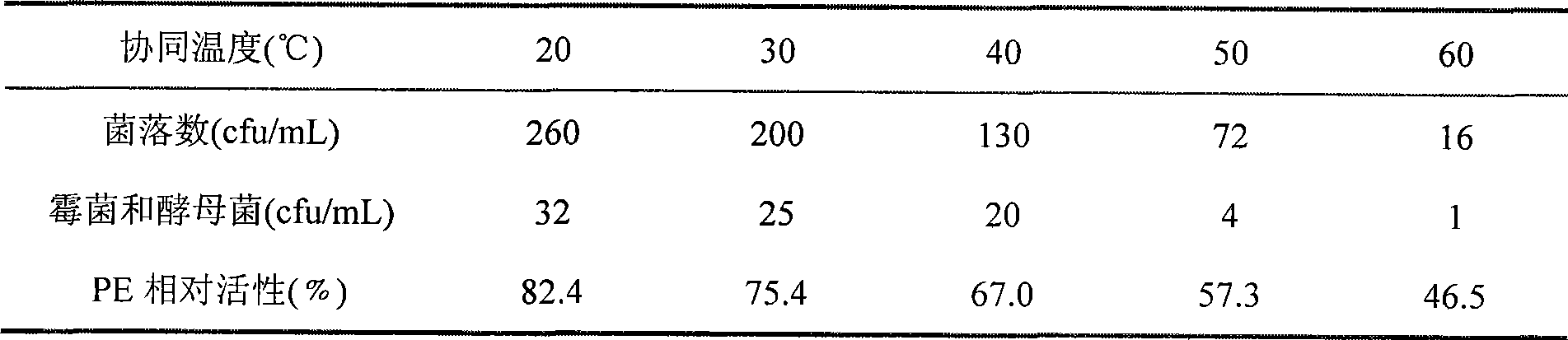

[0022] Select fresh pomelo, wash it, squeeze the juice and filter it. After blending, high-pressure homogenization and degassing, the pomelo juice is vacuum-packed, preheated, and placed in an ultra-high pressure container. At 50°C and 60°C, pressurize to 400MPa and hold the pressure for 10 minutes; release the pressure, take out the sample, and wipe off the moisture on the surface of the package.

[0023] The relative activity of microorganisms and PE in grapefruit juice samples after sterilization and enzyme removal was detected, and the results are shown in the following table:

[0024]

Embodiment 3

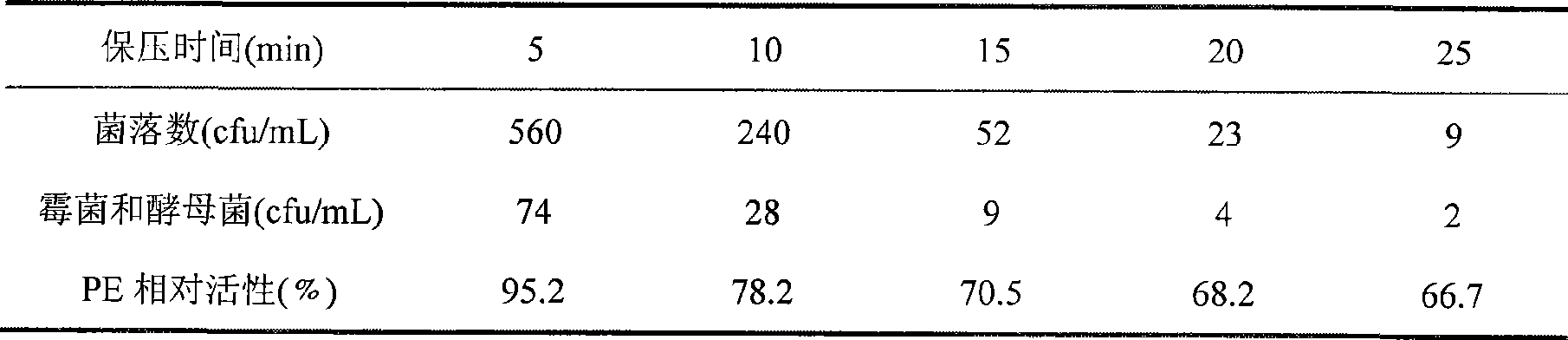

[0026] Choose fresh pomelo, wash it, squeeze the juice and filter it. After blending, high-pressure homogenization and degassing, vacuum pack the pomelo juice, preheat it to 25°C, put it in an ultra-high pressure container, and pressurize it to 25°C. 400MPa, hold the pressure for 5, 10, 15, 20, and 25 minutes respectively; release the pressure, take out the sample, and dry the moisture on the surface of the package.

[0027] The relative activity of microorganisms and PE in grapefruit juice samples after sterilization and enzyme removal was detected, and the results are shown in the following table:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com