Method and device for clearing rust-dirt and performing anticorrosion coating on metal pipelines

A technology for cleaning metal pipes and cleaning them. It is applied in coatings, devices for coating liquid on the surface, and surface pretreatment, etc., to achieve the effects of improving the passage of pipes, facilitating promotion, and uniform coating thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

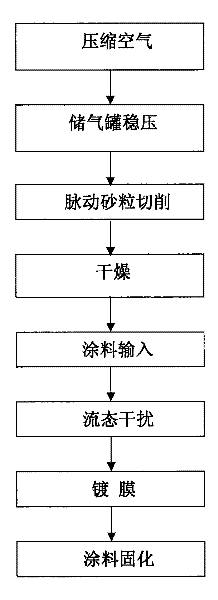

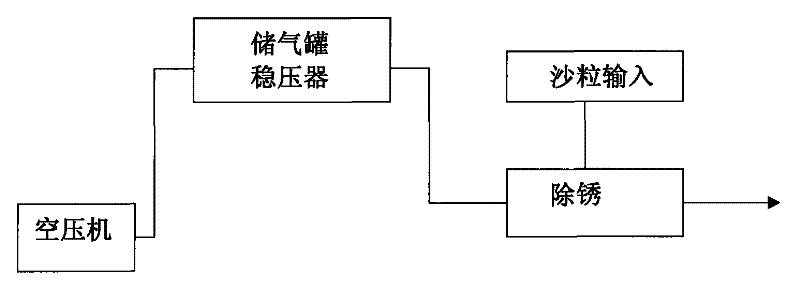

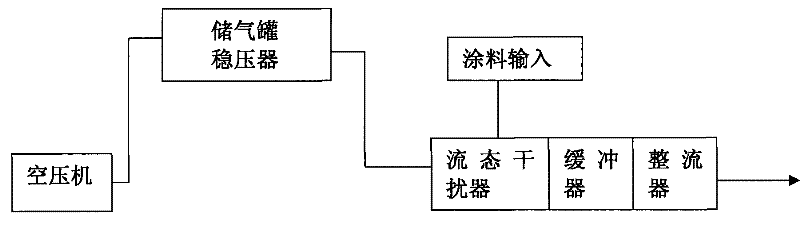

[0024] See Figure 1-8 , the equipment used in the method provided by the invention is as follows:

[0025] Including air compressors, gas storage tank regulators, soft pipe pigs, soft plastic dryers, buffers, rectifiers, flow state disruptors, etc. Among them, the air compressors, gas storage tank regulators, and buffers adopt existing technology. See Figure 4 , The soft pipe pig provided by the present invention is composed of a circular plug 2 formed by polyurethane foam at both ends, and an abrasive material 1 of natural sand or red steel grit in the middle. See Figure 5 , the soft plastic drier is composed of rubber supports 4 at both ends and plastic foam in the middle. See Figure 8 , The rectifier 9 is to set the cross rectifying plate in the circular tube. The flow disruptor is connected to the branch pipe 7 in the vertical direction of the axial flow pipe body 8, and the air valve 6 is arranged on the branch pipe 7. Figure 6 The shape of the buffer 5 is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com