Method for improving ratio of butanol produced from clostridium

A technology of proportional and solvent-producing Clostridium, which is applied in the field of bioengineering to achieve the effect of increasing the ratio of butanol

- Summary

- Abstract

- Description

- Claims

- Application Information

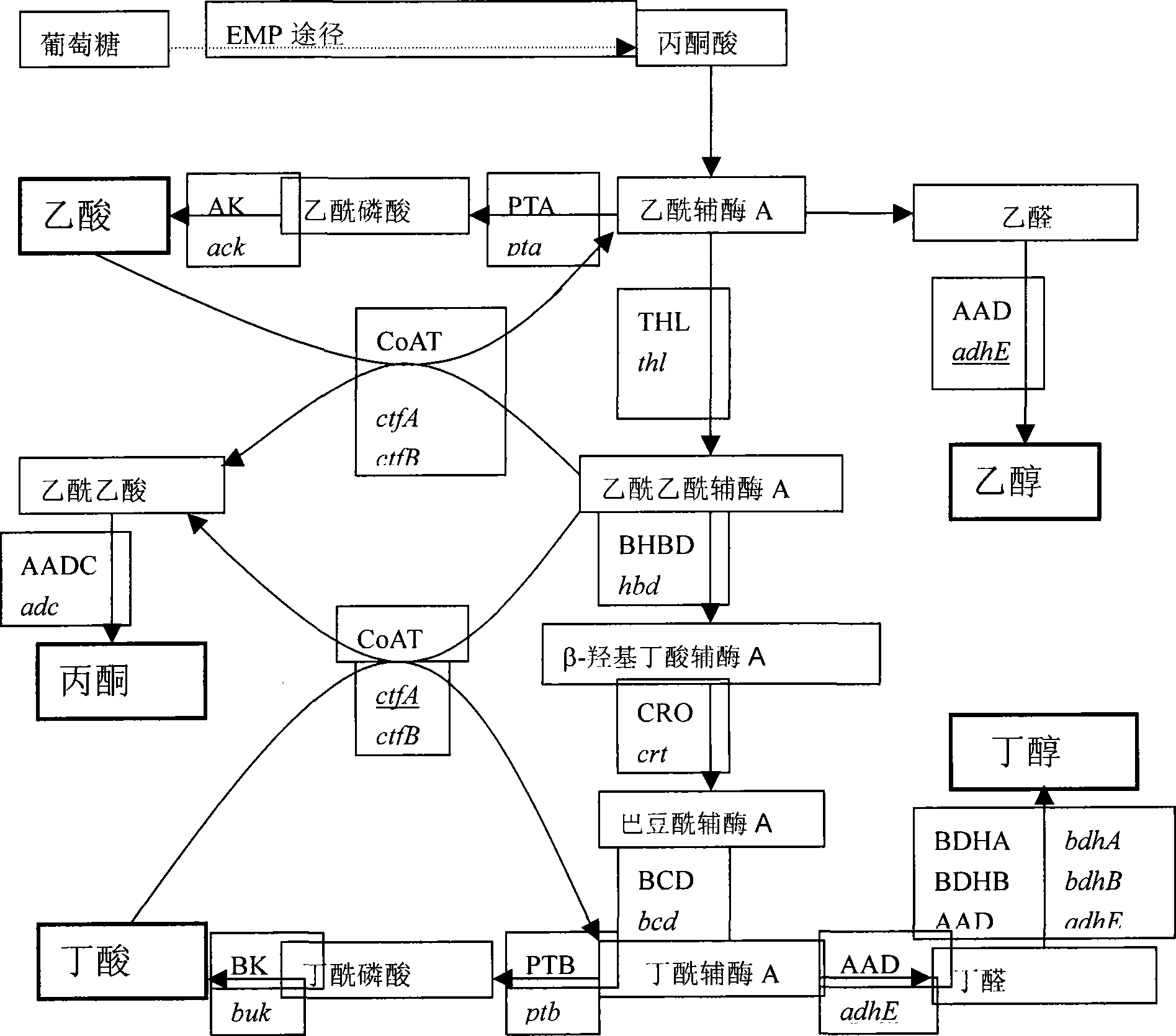

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

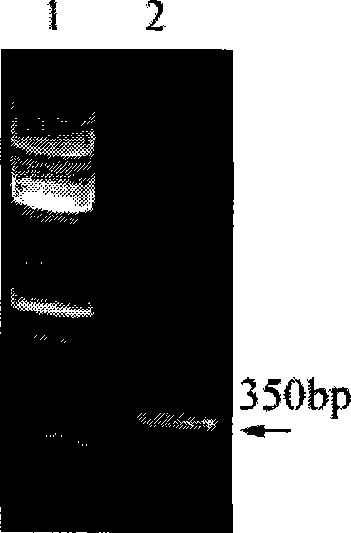

[0051] Example 1 , Construction of pSY6-adc plasmid vector

[0052] The adc targetron fragment was amplified by PCR, digested with XhoI and BsrG I, and connected to the pSY6 vector cut with the same restriction enzymes to obtain the knockout plasmid pSY6-adc. Among them, the template and primer design for amplifying the adc targetron are derived from the Targetron of Sigma-Aldrich Company TM Gene Knockout System (TA0100) Kit. Specific steps are as follows:

[0053] 1.1. Primer design

[0054] ReferenceTargetron TM The method provided by the Gene Knockout System (TA0100) Kit designed primers adc-IBS, adc-EBS1d and adc-EBS2 for constructing the pSY6-adc plasmid vector respectively, and their sequences were as follows:

[0055] adc-IBS:3'-aaaactcgagataattatccttattagtcaggtttgtgcgcccagatagggtg-5';

[0056] adc-EBS1d:3'-cagattgtacaaatgtggtgataacagataagtcaggtttgataacttacctttctttgt-5';

[0057] adc-EBS2:3'-tgaacgcaagtttctaatttcggttactaatcgatagaggaaagtgtct-5'.

[0058] At th...

Embodiment 2

[0067] Example 2 , Clostridium acetobutylicum ATCC824 adc gene knockout

[0068] After the pSY6-adc plasmid was methylated at the Cac8 I site by E.coli ER2275 / pANS, it was electroporated into Clostridiumacetobutylicum ATCC 824, and after recovery overnight, 100 μl of the cell liquid was applied to a 40 μg / ml Ery selective plate in an anaerobic box After culturing at 37°C for 48-96 hours, single bacteria were picked and verified by colony PCR. The specific steps are as follows:

[0069] 2.1. Methylation of pSY6-adc plasmid

[0070] Transform pANS into E.coli ER2275 to obtain E.coli ER2275 / pANS.

[0071] Prepare competent cells of E.coli ER2275 / pANS, and then transform the pSY6-adc plasmid into E.coliER2275 / pANS. Since the pANS plasmid has Spc resistance, put it on the LB medium plate containing 100μg / ml Amp and 50μg / mlSpc Cultivate overnight, and then pick a single colony into 4ml of LB medium supplemented with 100μg / ml Amp and 50μg / ml Spc, and culture overnight. Then, the...

Embodiment 3

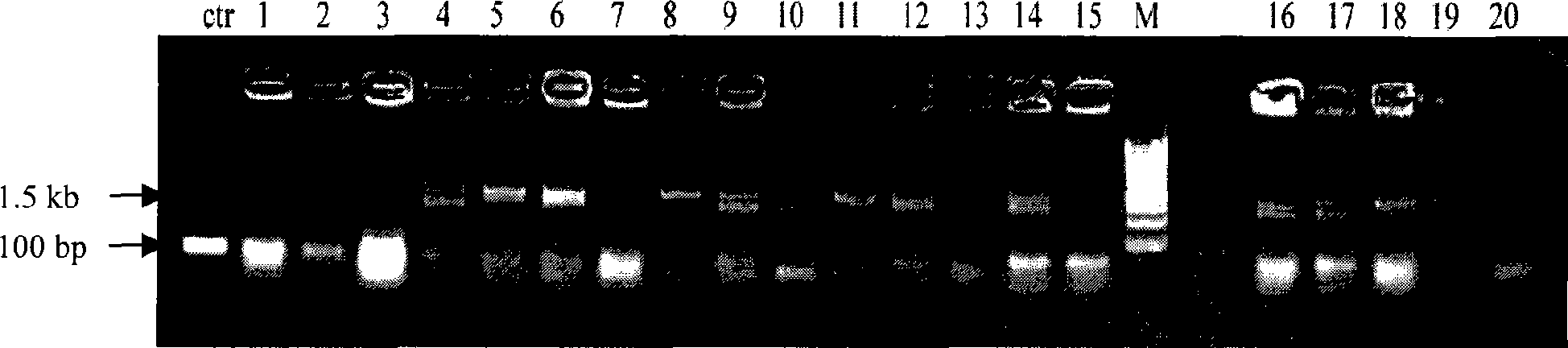

[0090] Example 3 , Clostridium acetobutylicum CCTCC M 94061 adc gene knockout

[0091] Using the same method as in Example 2, the plasmid pSY6-adc whose Cac824 I recognition site has been methylated was electroporated into C. acetobutylicum CCTCC M94061 to obtain the Ery-resistant C. acetobutylicum CCTCC M94061 transformant, and the transformation The child is verified, and the verification results are as follows:

[0092] After colony PCR amplification of the transformants of C.acetobutylicum CCTCC M 94061, the PCR amplification products were verified by electrophoresis, and the verification results were as follows Figure 5 shown, according to Figure 5 As a result, there were inserted recombinant bacteria in transformants 3, 4, 5, 6, 8, 9, 14, and 17, but because wild bacteria were mixed, the above 8 colonies needed to be further separated by streaking.

[0093] Perform colony PCR amplification of the single bacteria isolated by streaking, and verify the PCR product by el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com