Non-aqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of graphite material capacity not necessarily sufficient, charge-discharge cycle characteristics and other battery characteristics reduction, discharge characteristics reduction, etc., to achieve Effects of preventing degradation of charge-discharge cycle characteristics, suppressing decomposition of non-aqueous electrolyte, and improving charge-discharge cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

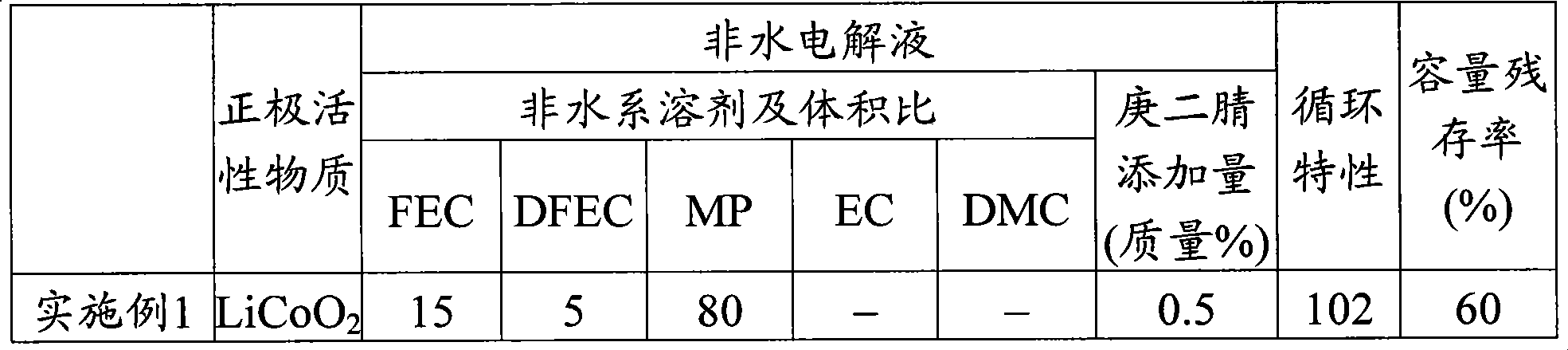

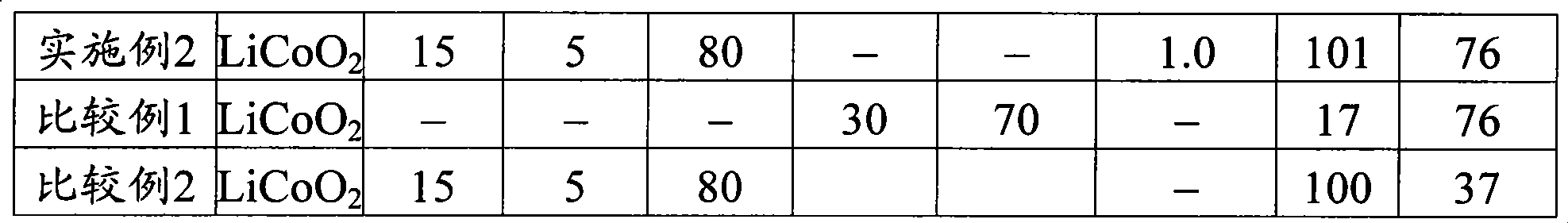

Embodiment 1

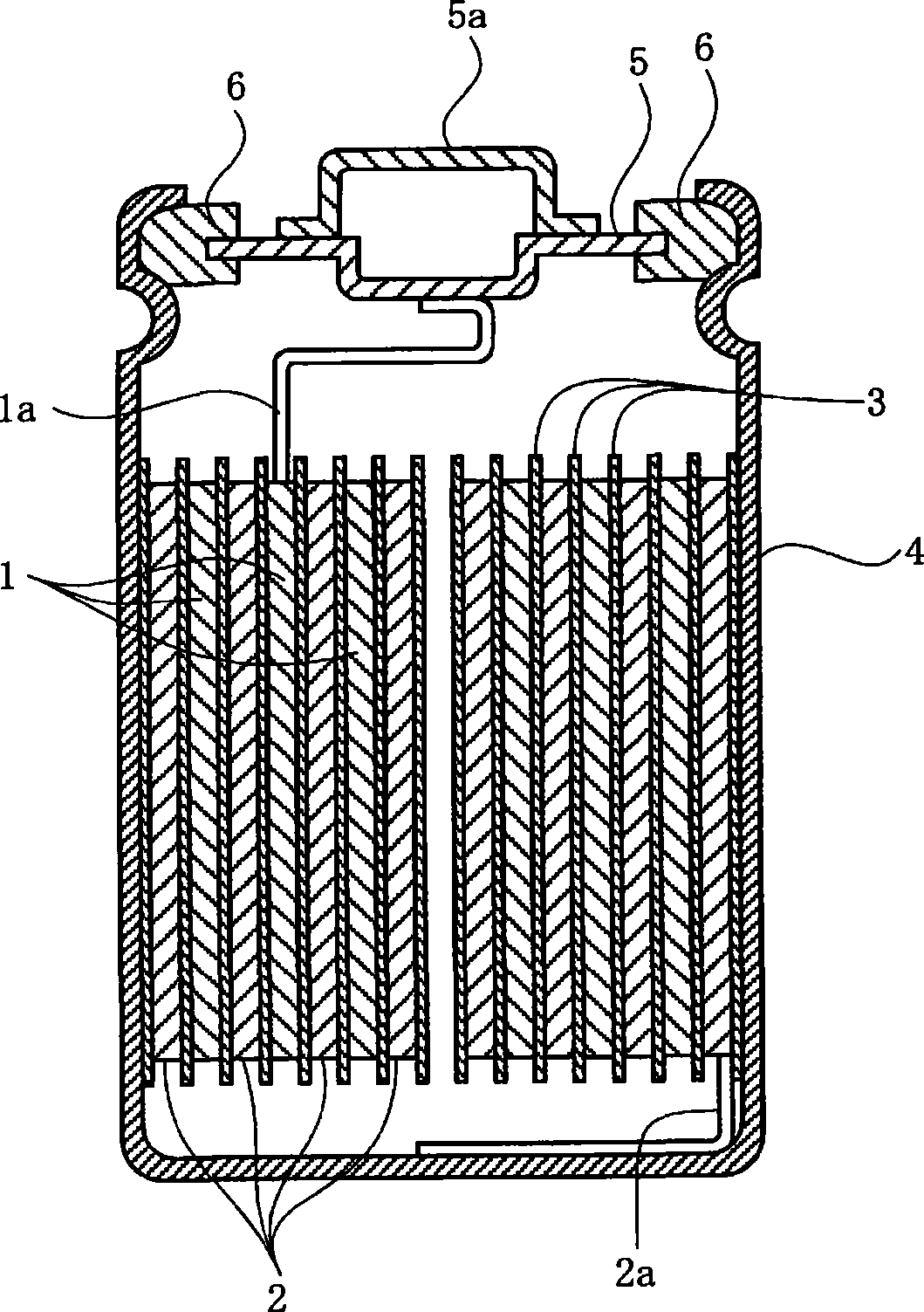

[0057] In Example 1, using the positive electrode, negative electrode, and non-aqueous electrolyte prepared as described below, a cylindrical shape with a diameter of 14 mm and a height of 43 mm with a design capacity of 950 mAh was manufactured. figure 1 The non-aqueous electrolyte secondary battery shown.

[0058] Production of positive electrode

[0059] When making the positive electrode, use LiCoO 2 Said lithium cobalt oxide (average particle size 13μm, BET specific surface area 0.35m 2 / g) As the positive electrode active material, mix the positive electrode active material, conductive agent carbon material powder, and binder polyvinylidene fluoride in a mass ratio of 95:2.5:2.5, and mix the N-methyl-2-pyrrolidone solution It is added to this mixture and kneaded to prepare a positive electrode mixture slurry.

[0060] Then, the positive electrode mixture slurry was coated on both sides of a positive electrode current collector made of aluminum foil with a thickness of 15 ...

Embodiment 2

[0070] In Example 2, the non-aqueous electrolyte secondary battery of Example 2 was produced in the same manner as in Example 1, except that when the non-aqueous electrolyte was prepared in Example 1, the above-mentioned nitrile compound was added to the non-aqueous electrolyte. That is, the amount of pimelic nitrile is 1.0% by mass.

Embodiment 3

[0089] In Example 3, the non-aqueous electrolyte secondary battery of Example 3 was produced in the same manner as in Example 1, except that when the non-aqueous electrolyte was prepared in Example 1, succinonitrile was used as the non-aqueous electrolyte. The added amount of the added nitrile compound having a chain saturated hydrocarbon group with a carbon number of 2 or more is 1.0% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Filling density | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com