Plasma filming apparatus, and plasma filming method

A plasma and film-forming device technology, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problems of inability to obtain energy, low film-forming rate, and deterioration of uniformity within the film thickness, etc. Effects of preventing decrease in electron density, maintaining in-plane uniformity, and high film formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

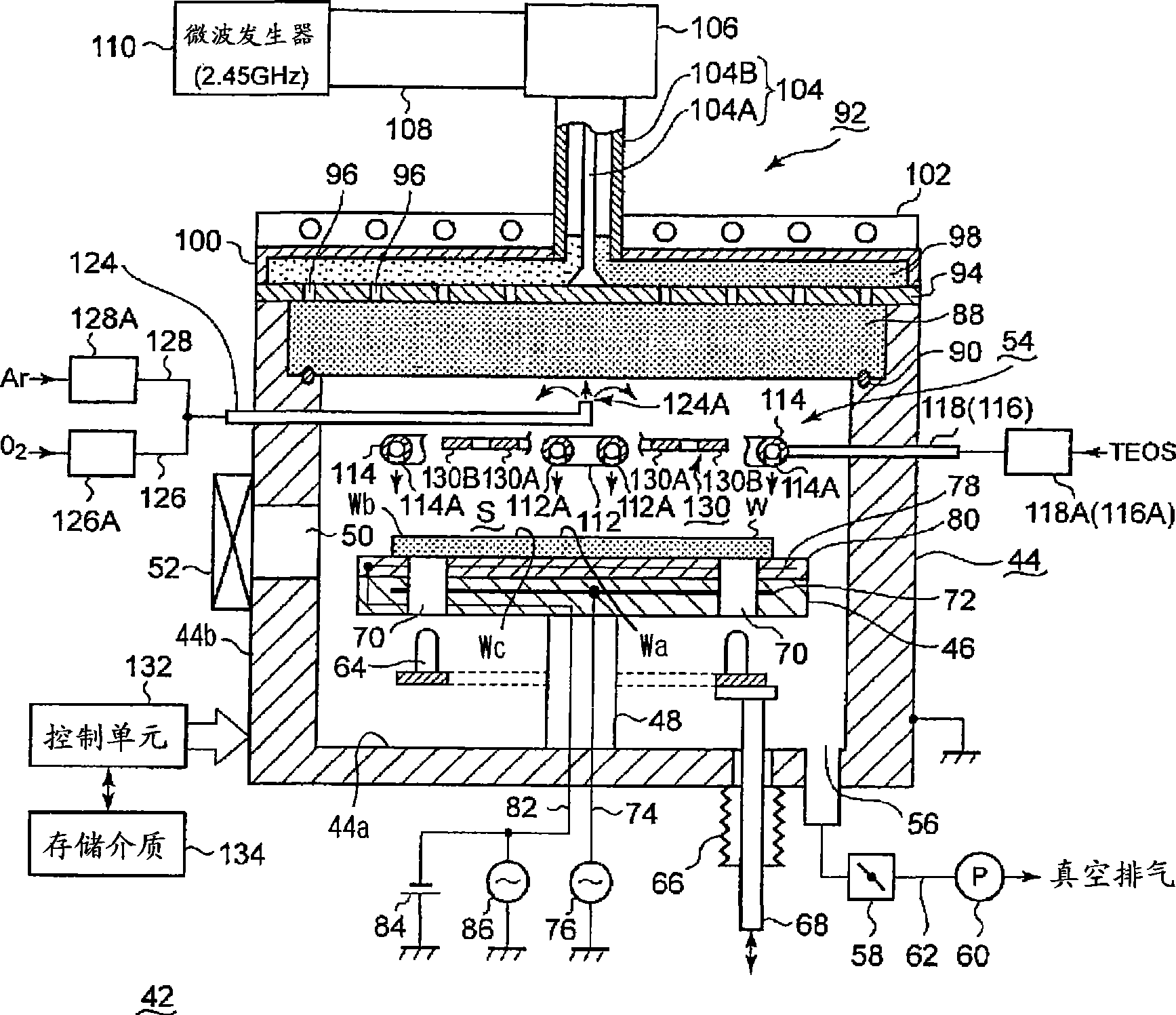

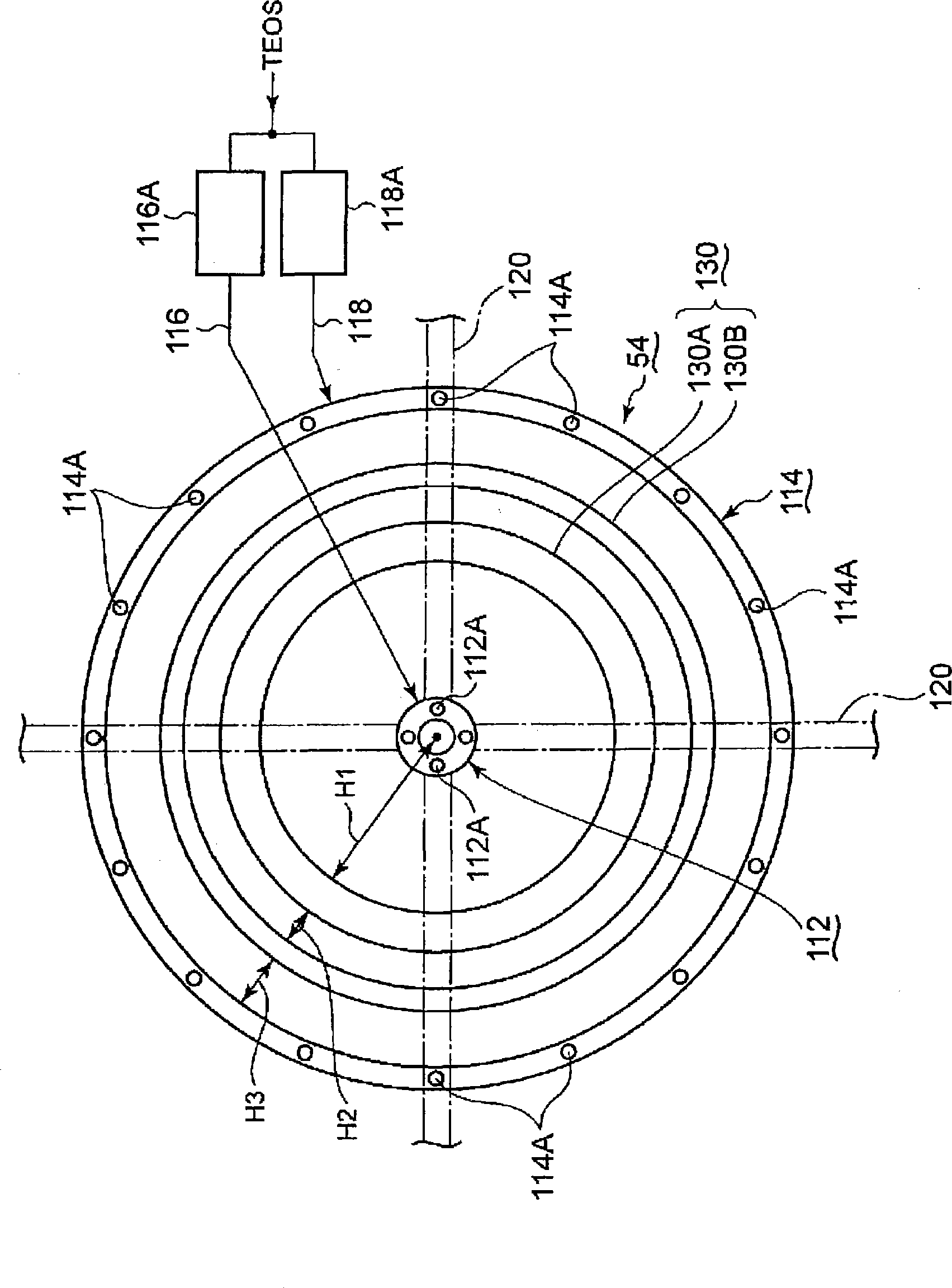

[0055] figure 1 is a configuration diagram showing the first embodiment of the plasma film forming apparatus of the present invention, figure 2 It is a plan view showing the state when the gas introduction unit is viewed from below. Here, TEOS is used as the source gas, and O for oxidation is used as the auxiliary gas. 2 Ar gas for gas and plasma stabilization to form SiO by plasma CVD 2 The case of a thin film composed of a film will be described as an example. In addition, a rare gas such as Ar may be added to the above-mentioned TEOS as needed.

[0056] As shown in the figure, the plasma film forming apparatus 42 has a processing container 44. The side wall and bottom of the processing container 44 are made of conductors such as aluminum, and are integrally formed in a cylindrical shape. The inside of the processing container 44 is sealed, such as circular. A processing space S in which plasma is formed. The processing container 44 itself is grounded.

[0057] A mou...

no. 2 Embodiment

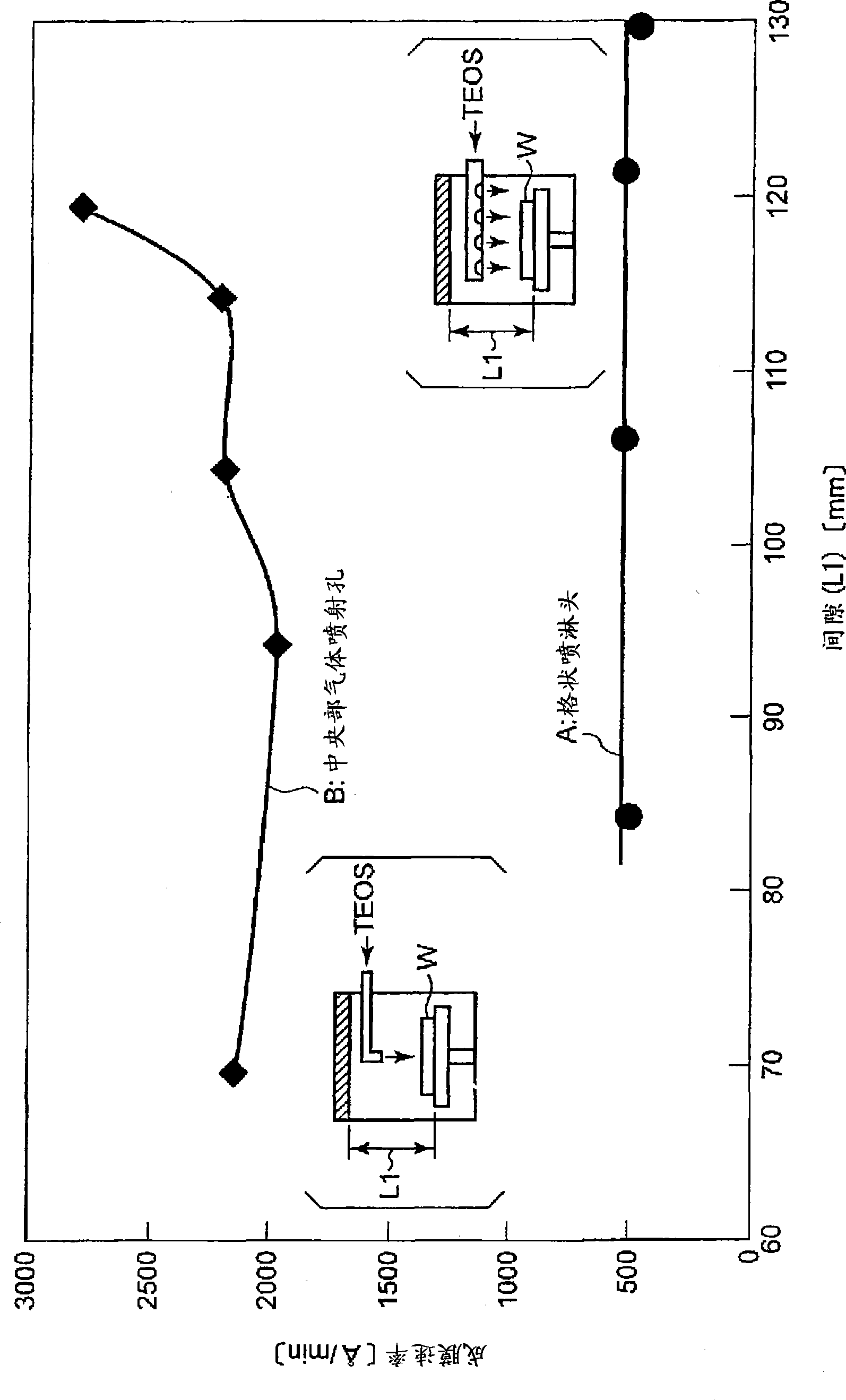

[0114] On the lower surface, a second embodiment of the plasma processing apparatus of the present invention will be described. before using figure 1 The shown first embodiment of the apparatus can improve the in-plane uniformity of the film thickness to a certain extent while maintaining a high film formation rate, but it is desired to further improve the in-plane uniformity of the film thickness. In the previous first embodiment, the assist gas injection hole 124A of the assist gas nozzle portion 124 was provided in the center, thereby supplying O 2 gas, etc., but in order to improve the in-plane uniformity of the film thickness, it is necessary to make the O 2 Shower head structure in which gas and the like are uniformly supplied to the entire processing space S without shielding microwaves. Therefore, in the second embodiment, the top plate 88 forming the top of the processing container is provided with the function of the shower head.

[0115] Figure 7 A schematic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com