Method for preparing spherical bimetallic MCo-MOFs catalytic material through microwave-ultrasonic wave synergistic assistance

A catalytic material and bimetallic technology, which is applied in chemical instruments and methods, catalytic reactions, catalyst activation/preparation, etc., can solve the problem of spherical bimetallic MCo-MOFs catalytic materials, which are difficult to obtain regular, orderly and three-dimensional Material, catalytic diolefin epoxidation performance is not ideal, etc., to achieve the effect of fast heating speed, fast reaction and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

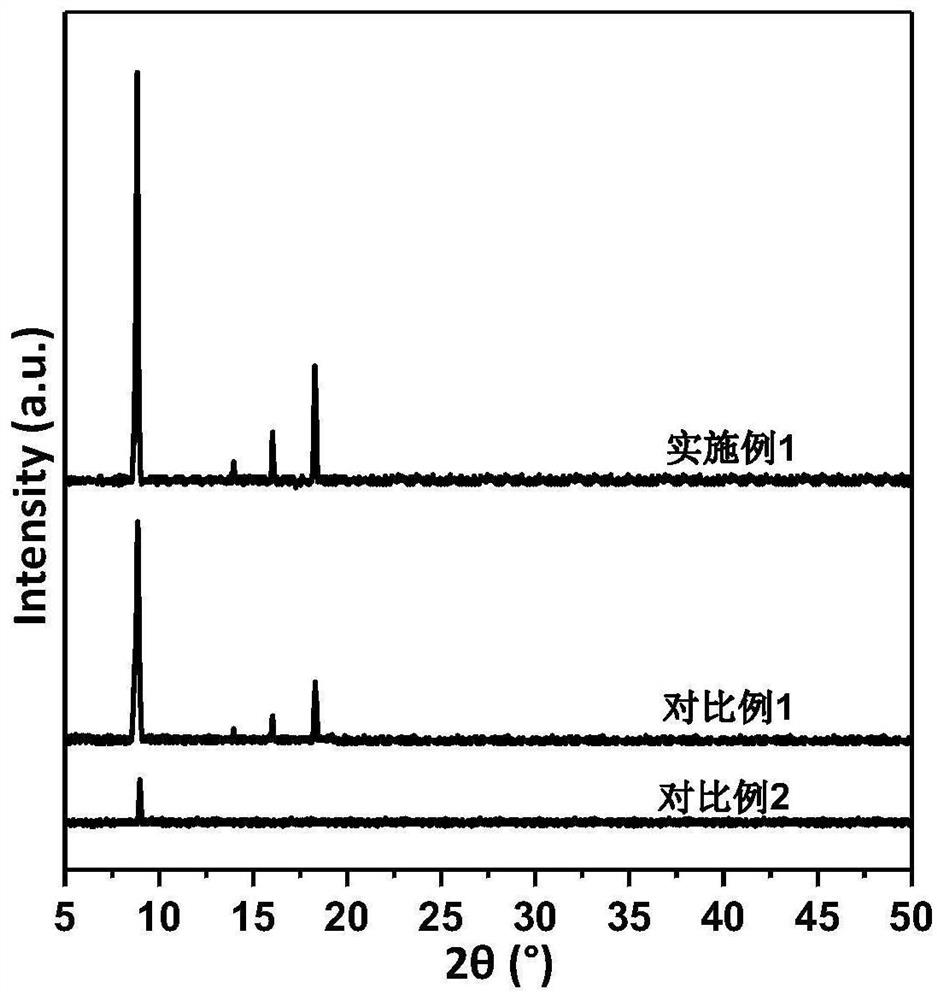

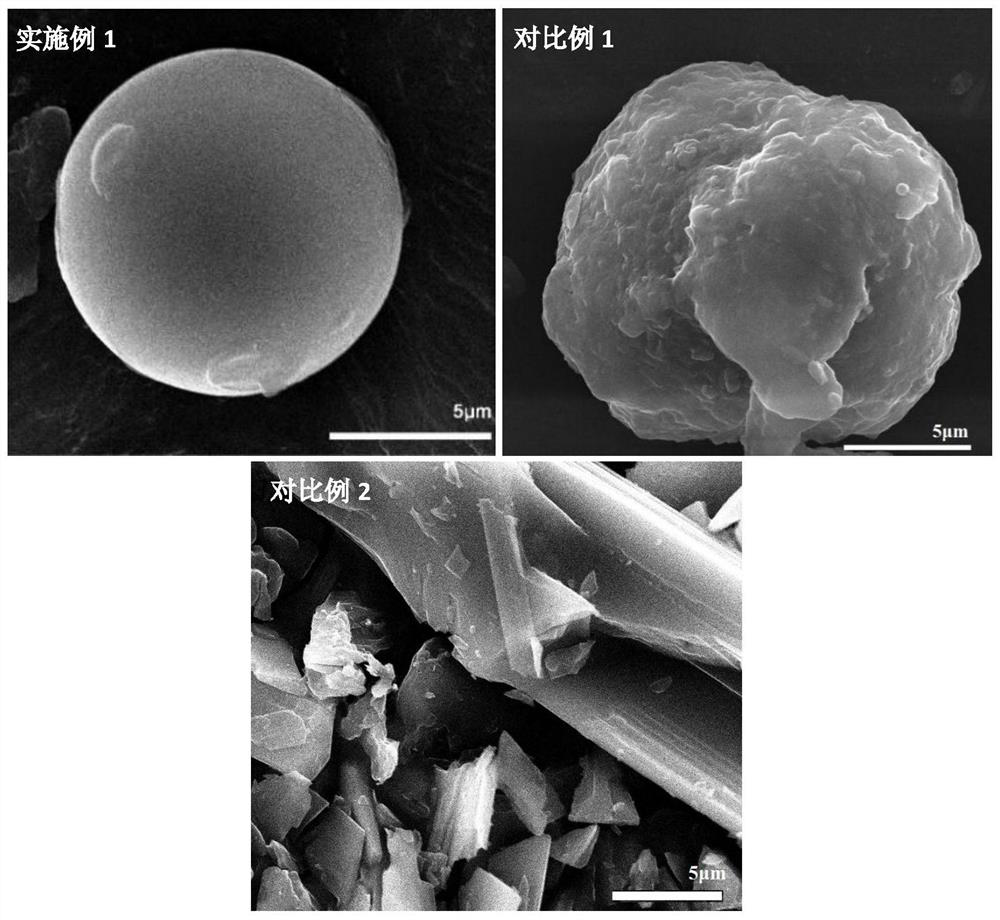

[0037] 1) First weigh 12mmol of cobalt acetate, 1.2mmol of zinc nitrate and 12mmol of terephthalic acid into a round-bottomed flask of 6.84mol of water, mix well and place in a microwave-ultrasonic integrated reactor. Set the microwave power to 100W and the ultrasonic power to 100W. 500W, reaction temperature 80℃, microwave and ultrasonic synergistic reaction for 2h, bimetallic Zn 0.1 Co-MOFs precursor solution;

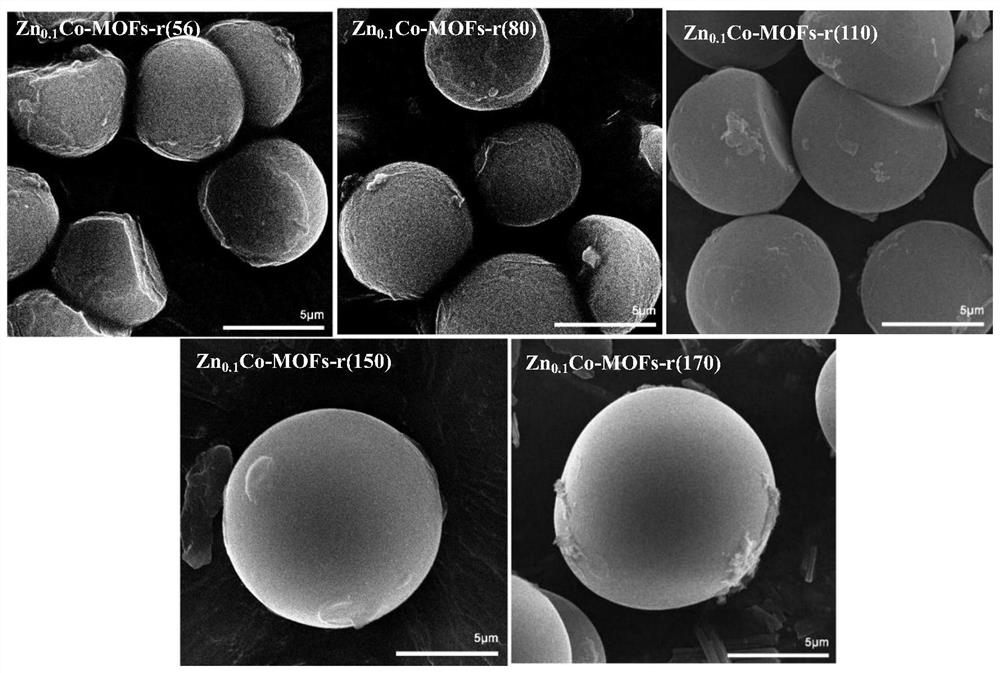

[0038] 2) Transfer the precursor reaction solution obtained in step 1) into a polytetrafluoroethylene lining, then place the lining in a stainless steel reactor, then seal the reactor, and place the reactor in a rotary crystallization reactor, Set the rotational speed to 150r / min, the crystallization temperature to 200°C, and the crystallization time to 3h, and perform rotational hydrothermal crystallization treatment to obtain bimetallic Zn 0.1 Crude Co-MOFs;

[0039] 3) The product obtained in step 2) is sequentially washed with DMF and ethanol (85° C.), suction ...

Embodiment 2

[0041] 1) First weigh 9mmol of cobalt nitrate, 1.8mmol of bismuth nitrate and 9mmol of terephthalic acid into a round-bottomed flask with 4.5mol of water, mix well and place in a microwave-ultrasonic integrated reactor, set the microwave power to 300W, ultrasonic The power is 400W, the reaction temperature is 80°C, and the microwave and ultrasonic waves are synergistically reacted for 1h to obtain bimetallic Bi 0.2 Co-MOFs precursor solution;

[0042] 2) Transfer the precursor reaction solution obtained in step 1) into a polytetrafluoroethylene lining, then place the lining in a stainless steel reactor, then seal the reactor, and place the reactor in a rotary crystallization reactor, Set the rotational speed to 150r / min, the crystallization temperature to 200°C, and the crystallization time to 4h, and perform rotational hydrothermal crystallization treatment to obtain bimetallic Bi 0.2 Crude Co-MOFs;

[0043] 3) The product obtained in step 2) was sequentially washed with DM...

Embodiment 3

[0045] 1) First weigh 12mmol of cobalt acetate, 3.6mmol of tin chloride and 12mmol of terephthalic acid into a round-bottomed flask with 4.44mol of water, mix well and place in a microwave-ultrasonic integrated reactor, set the microwave power to 200W, ultrasonic The power is 600W, the reaction temperature is 70℃, and the microwave and ultrasonic synergistic reaction is 3h, and the bimetallic Sn 0.3 Co-MOFs precursor solution;

[0046] 2) Transfer the precursor reaction solution obtained in step 1) into a polytetrafluoroethylene lining, then place the lining in a stainless steel reactor, then seal the reactor, and place the reactor in a rotary crystallization reactor, Set the rotational speed to 150r / min, the crystallization temperature to 200°C, and the crystallization time to 1h, and perform rotational hydrothermal crystallization treatment to obtain bimetallic Sn 0.3 Crude Co-MOFs;

[0047] 3) The product obtained in step 2) was sequentially washed with DMF and ethanol (8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com