Two-step microcapsule preparation method in bio-artificial reaction device

A reaction device and bioartificial technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of reduced microcapsule wall integrity, integrity and airtight damage, and reduced function of cell materials in the capsule microcapsule. , to achieve the effect of maintaining immune isolation, good social and economic benefits, and good immune isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

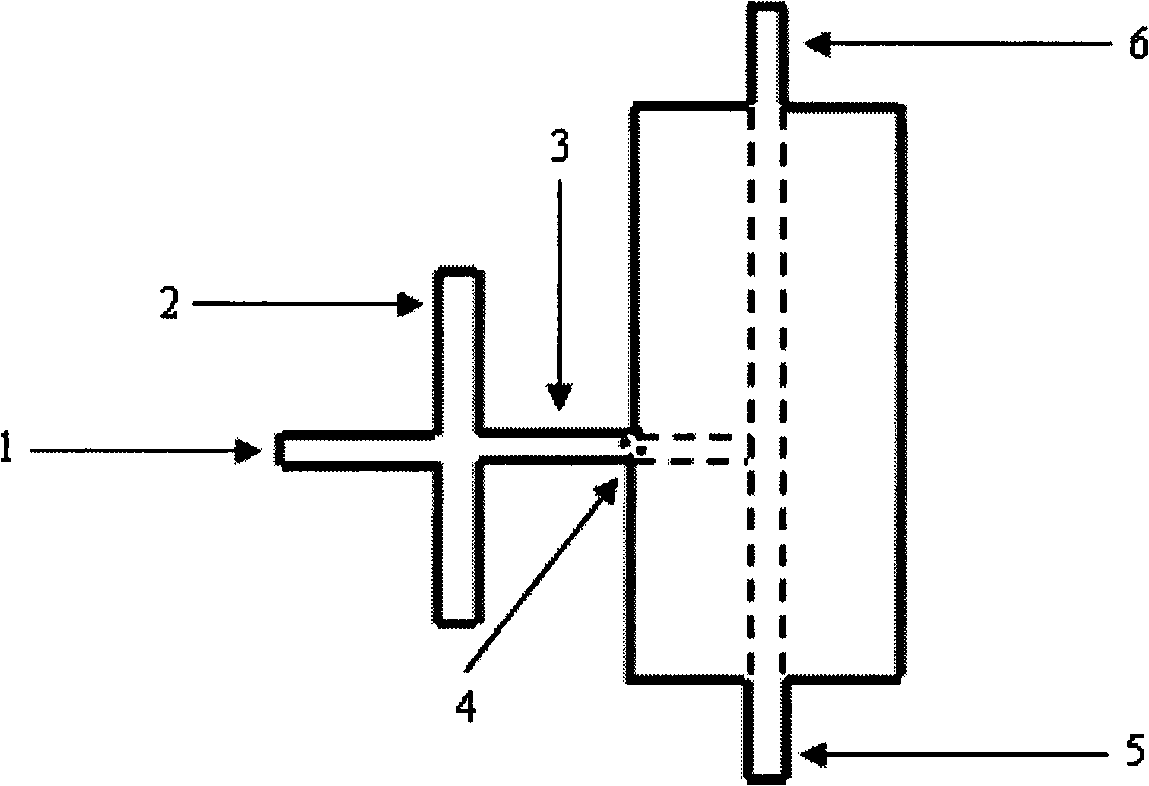

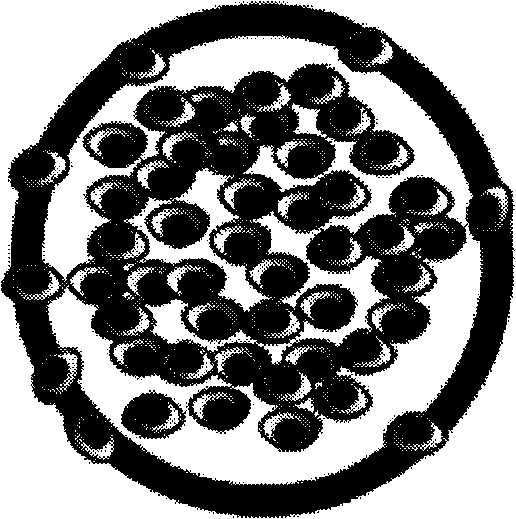

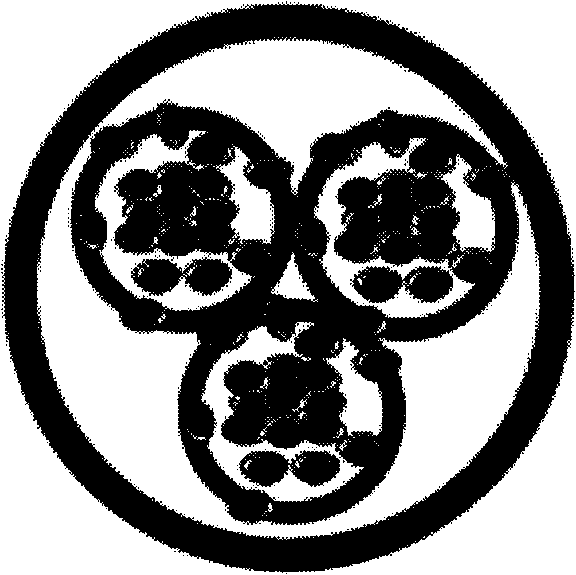

[0026] Select biological cell materials such as hepatocytes according to different purposes, fully mix the hepatocytes with 2% sodium alginate solution according to the ratio required for different purposes, and put them into the microcapsule generator, that is, in the jet microcapsule generator Oxygen enters into the microcapsule generator through the gas inlet 1, disinfection filter 2, air flow channel 3 and sealing ring 4, and sprays into the 100mmol / L calcium chloride solution through the disinfection nozzle 5 at a drop rate of 50ml / h , to make it gel; after 10 minutes, absorb the calcium chloride solution, wash with normal saline for 3 times, then react with 0.1% polylysine solution for 15 minutes, wash with normal saline solution for 3 times; react with 0.15% sodium alginate solution For 12 minutes, wash with normal saline solution 3 times; collect the one-step microcapsule method microcapsules prepared above and mix them well with 2% sodium alginate solution, put them in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com