Method for preparing chitosan/organo montmorillonite nanometer composite material

A nano-composite material, organic montmorillonite technology, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effect of improving utilization and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

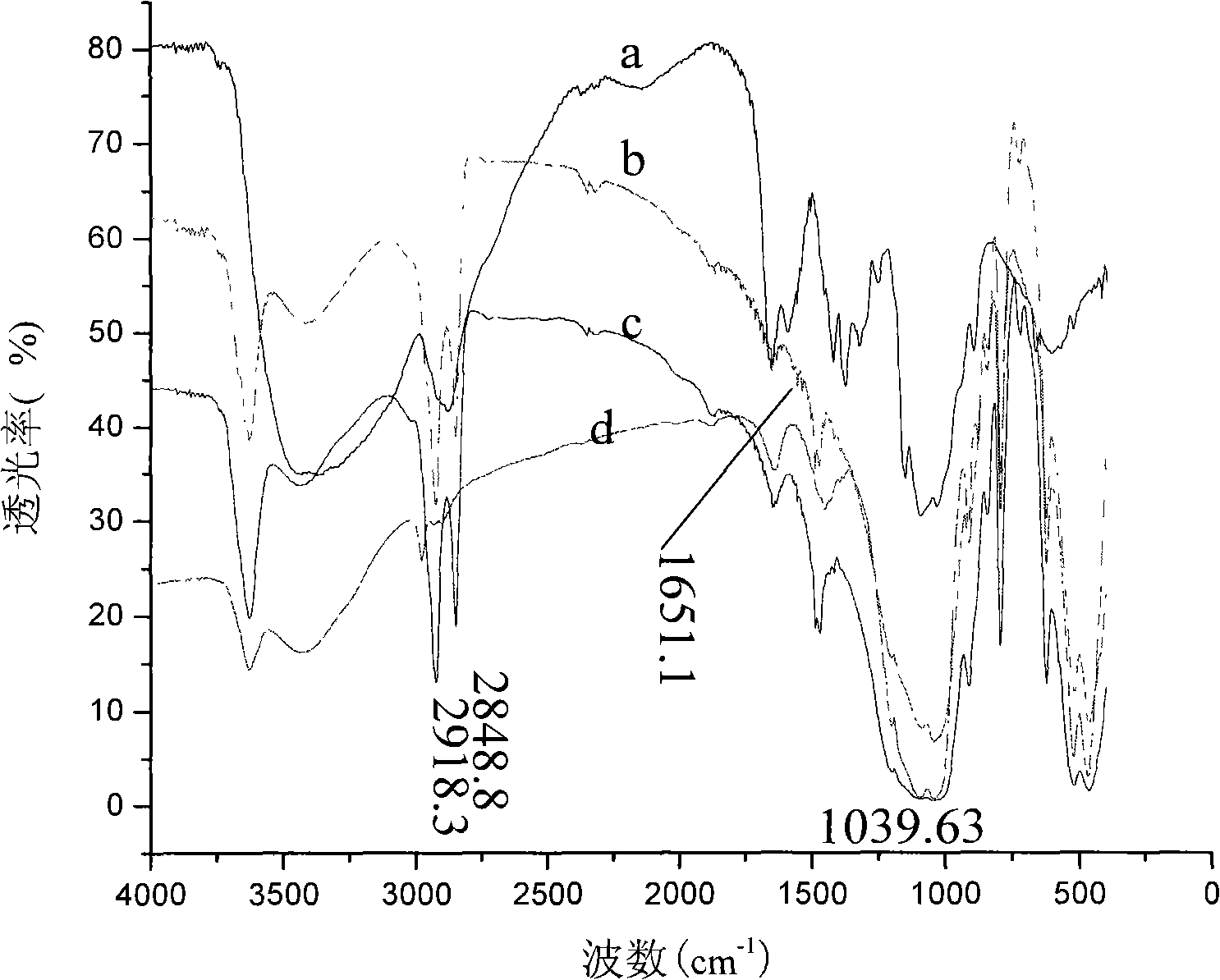

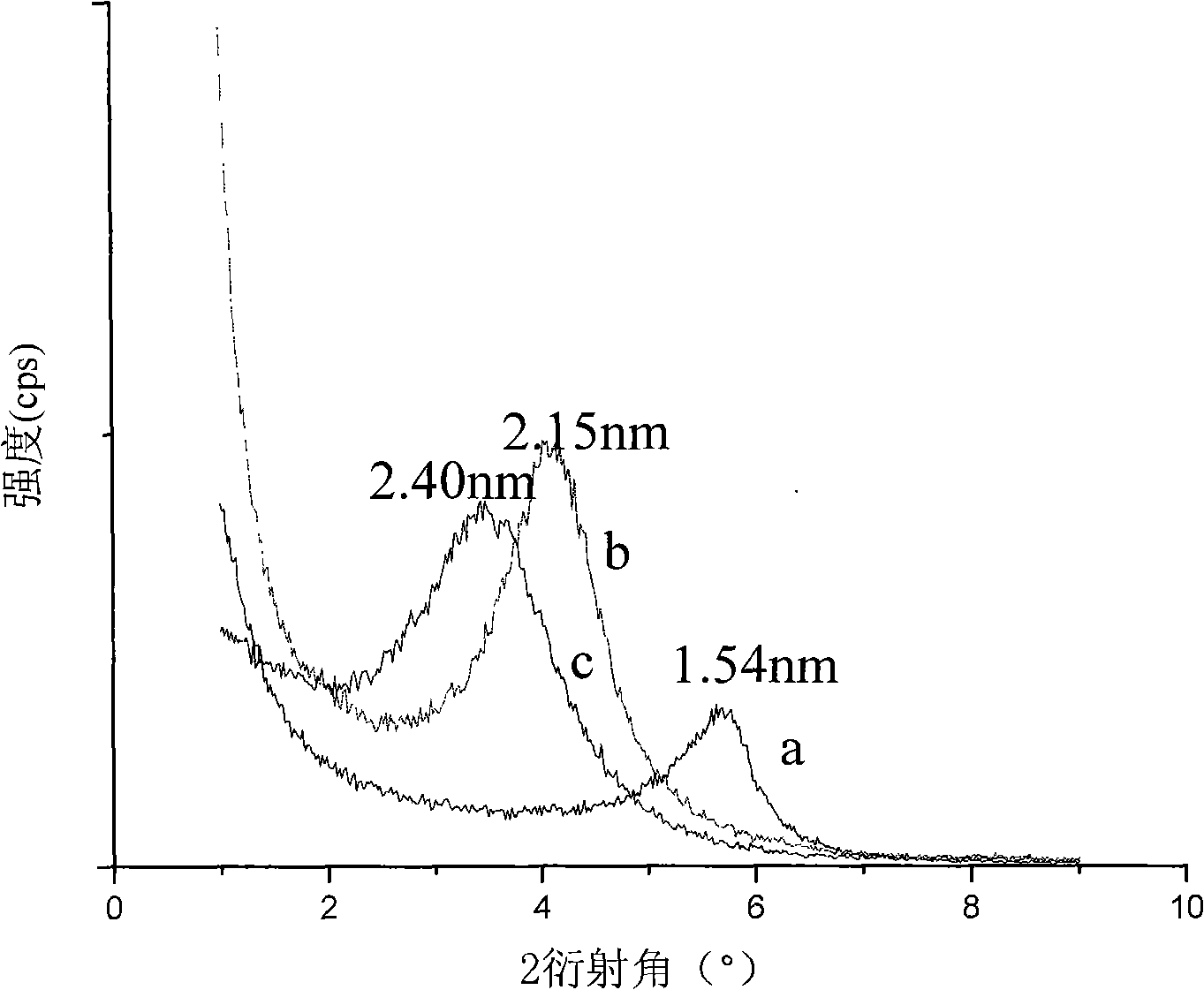

[0022] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0023] Purification of Montmorillonite:

[0024] Prepare the montmorillonite into a 7% (w / w) suspension, stir it electrically for 15 minutes, let it stand for 10 minutes, pour out the upper liquid, discard the sand at the bottom, and add a certain amount of water to make the mass fraction of the montmorillonite approx. 5%, stir for 20 minutes, let stand for 20 minutes, discard the sand at the bottom, evaporate the above liquid to dryness at 95°C, and grind through a 100-mesh sieve.

[0025] Organicization of Montmorillonite:

[0026] Weigh a certain amount of purified montmorillonite, add deionized water to prepare a suspension with a mass concentration of 8%, measure 100ml into a 250ml Erlenmeyer flask, and stir for 30min in a water bath at 60°C. Dissolve 2.4g of cetyltrimethylammonium bromide in 50ml of deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com