Method for reclaiming aliphatic carboxylic acid

A technology of aliphatic carboxylic acid and aliphatic carboxylic acid ester, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of large steam consumption, reduce the circulation volume, reduce the consumption, solve the problem of high steam consumption, etc. The effect of a large amount of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

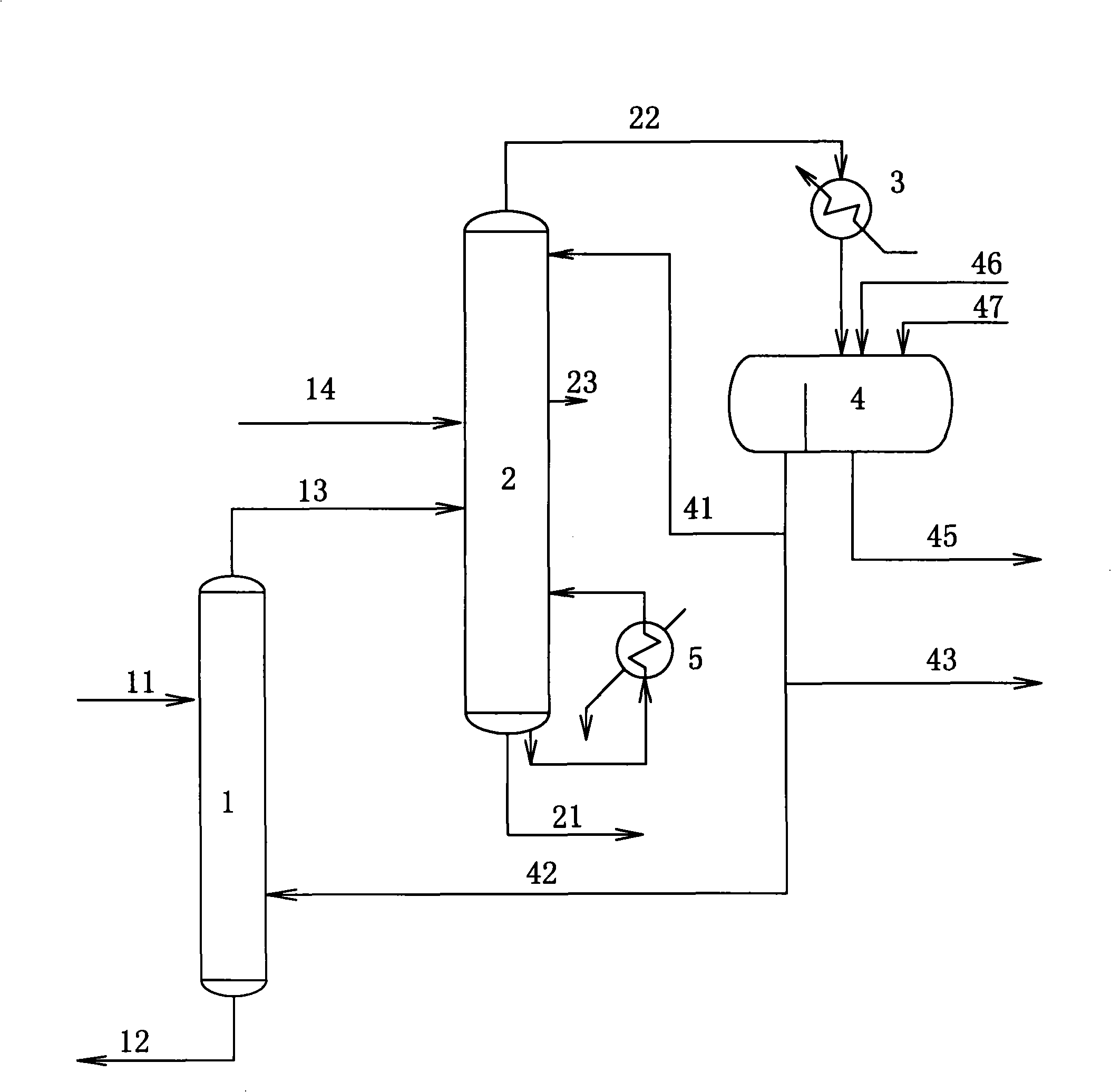

[0060] For the specific process of the embodiment, please refer to figure 2 , the amount of material in the present embodiment is based on parts by mass.

[0061] In the stream 11 of the mixture to be separated, the feed amount of the mixture per unit time contains 70.8 parts of acetic acid, 60.75 parts of water, 0.1 part of p-xylene, and 0.3 part of methyl acetate.

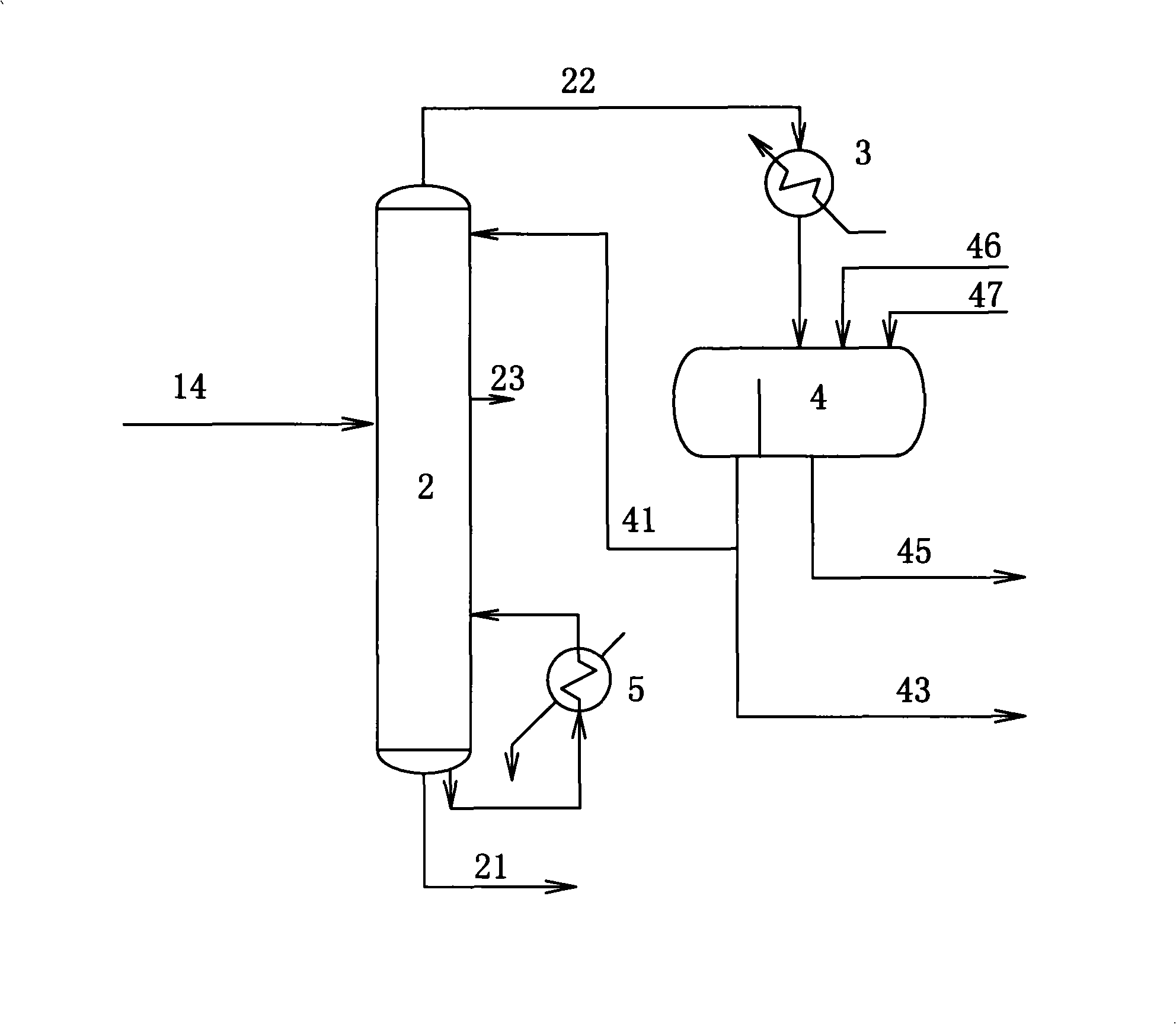

[0062] In the stream 14 of the mixture to be separated, the feed amount of the mixture per unit time contains 256.6 parts of acetic acid, 132.15 parts of water, 0.35 parts of p-xylene, and 8.3 parts of methyl acetate.

[0063] The extraction tower 1 is a plate tower, and the mixture flow 11 is fed from the upper part of the extraction tower 1.

[0064] Stream 42 provides the extraction agent isobutyl acetate required for extraction, and the supply content of isobutyl acetate is 271.4 parts.

[0065] The operating conditions of the extraction tower 1 are selected at a temperature of 40-50°C and an operating pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com