Method for producing straw fermented feed by using apple juice concentrations and straws as raw materials

A fermented feed and apple juice technology, applied in animal feed, animal feed, application, etc., can solve the problems of poor palatability, indigestibility of animals, low protein content, etc., to improve palatability, digestion and absorption rate, nutritional content and characteristics Strong complementarity, the effect of improving digestion and absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Cut the corn stalks into short pieces and crush them into 3-4 cm long, mix the apple juice concentrate and corn stalks in a mass ratio of 3:7, control the water content at about 65%, and inoculate yeast, Lactobacillus plantarum and Lactobacillus acidophilus at the same time , sealed in the cellar, and fermented at 23°C for 40 days to open the cellar for use. After fermentation, the pH value can reach below 4.5, which is suitable for preservation.

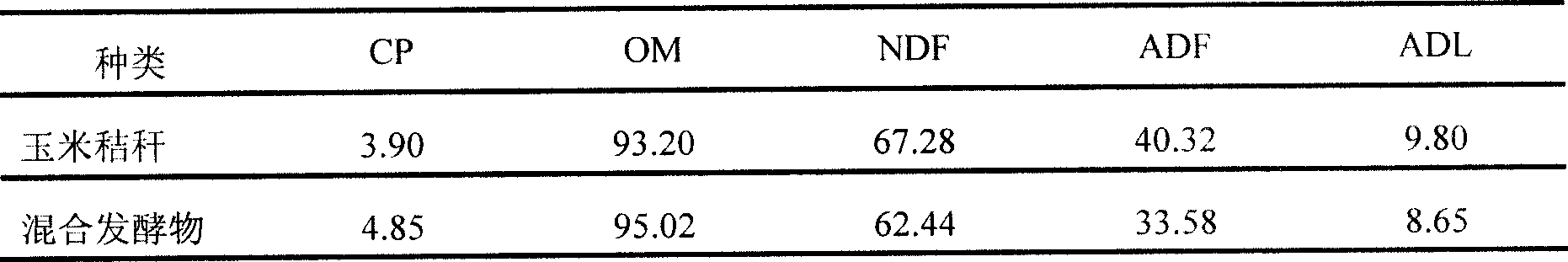

[0014] Table 1 Nutrient content of apple juice concentrate and corn stalk mixed fermentation product and ordinary corn stalk (%)

[0015]

[0016] The fermented feed was used to feed mid-lactation dairy cows with a milk yield of 20-25 kg. The roughage was common corn stalks in the control group, and the mixed fermented product of apple juice concentrate and corn stalks in the test group. The roughage in each group was 20 kg. Concentrates are 10 kg and the nutrients are the same, the average milk production of the test gro...

Embodiment 2

[0020] Cut the corn stalks to 3-4 cm long, mix the apple juice concentrate and corn stalks (cut the stalks to 3-4 cm long) in a mass ratio of 4:6, keep the water content at about 70%, and inoculate at the same time Yeast, Lactobacillus plantarum, and Lactobacillus acidophilus are sealed in cellars and fermented at 24°C for 42 days before being opened for use. After fermentation, the pH value is 4.5, which is suitable for preservation.

[0021] Table 3 Nutrient content of apple juice concentrate and corn stalk mixed fermentation product and ordinary corn stalk (%)

[0022]

[0023] The fermented feed was used to feed mid-lactation dairy cows with a milk yield of 20-25 kg. The roughage was common corn stalks in the control group, and the mixed fermented product of apple juice concentrate and corn stalks in the test group. The roughage in each group was 20 kg. Concentrates are 10 kg and the nutrients are the same, the average milk production of the test group is 2.2 kg / day hi...

Embodiment 3

[0027] Cut the corn stalks to 3-4 cm long, mix the apple juice concentrate and corn stalks (cut the stalks to 3-4 cm long) in a mass ratio of 5:5, control the water content at about 75%, and put it in a cellar Sealed and fermented at 25°C for 45 days before opening the cellar for use. After fermentation, the pH value is 4.5, which is suitable for preservation.

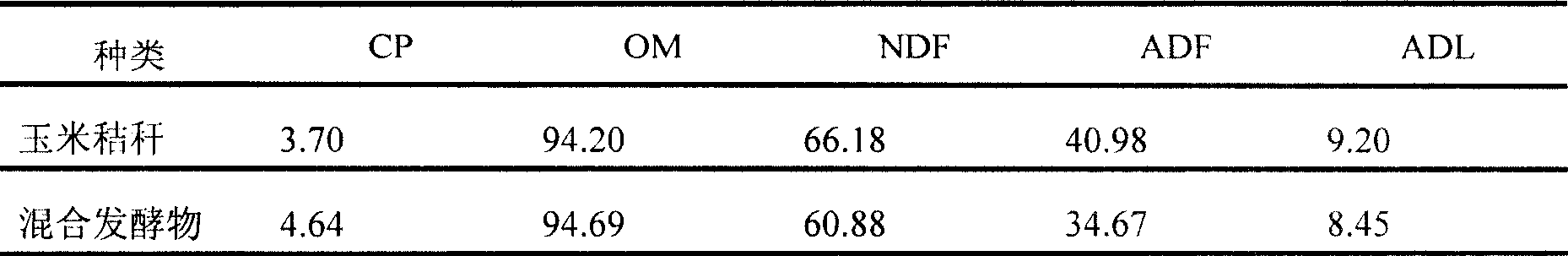

[0028] Table 3 Nutrient content of apple juice concentrate and corn stalk mixed fermentation product and ordinary corn stalk (%)

[0029]

[0030] The fermented feed was used to feed mid-lactation dairy cows with a milk yield of 20-25 kg. The roughage was common corn stalks in the control group, and the mixed fermented product of apple juice concentrate and corn stalks in the test group. The roughage in each group was 20 kg. Concentrates are 10 kg and the nutrients are the same, the average milk production of the test group is 2.2 kg / day higher than that of the control group.

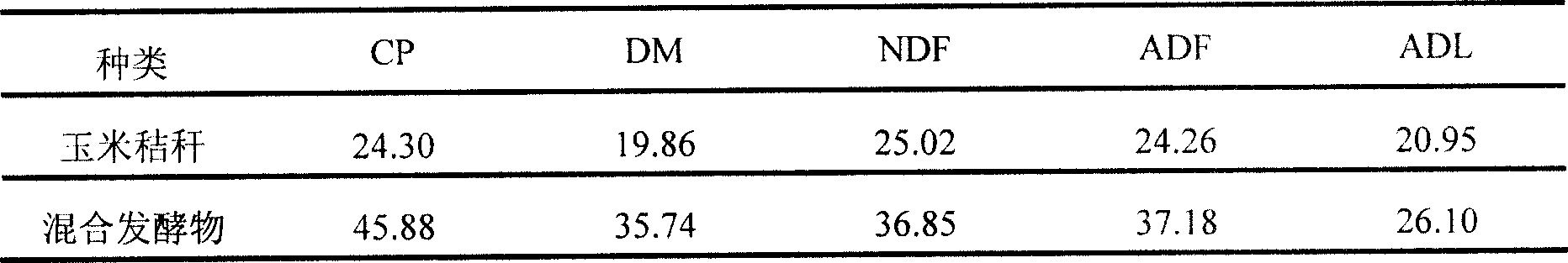

[0031] Degradation rate of nutrients...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com