Polyether-based polycarboxylic acid series hyper-dispersant and synthetizing method

A technology of polyether-based polycarboxylic acid and hyperdispersant, which is applied in the field of cement concrete hyperdispersant and its synthesis, polyether-based polycarboxylic acid hyperdispersant and its synthesis, and can solve the problem of large slump loss and environmental problems. Pollution, few practical applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

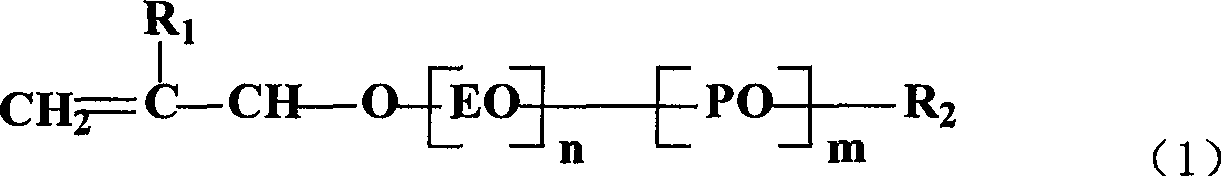

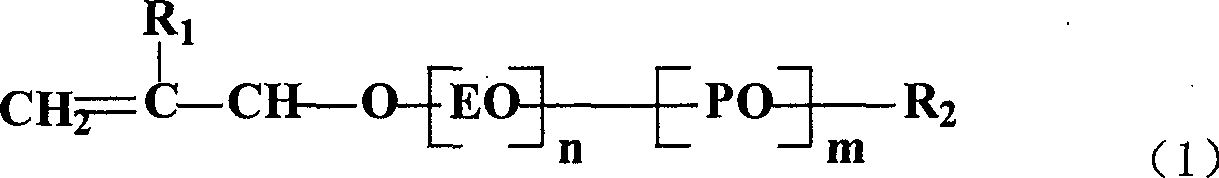

[0030] The monomer A used in the preparation process of the copolymer of the present invention will be described below, wherein stands for polyoxyethylene, Represents a polyoxypropylene group.

[0031] A-1: Allyl polyglycol ether (added The average molecular weight of 400);

[0032] A-2: Allyl polyglycol ether (added The average molecular weight of 1000);

[0033] A-3: Allyl polyglycol ether (added The average molecular weight of 1300);

[0034] A-4: Allyl polyglycol ether (added The average molecular weight of 2000);

[0035] A-5: Allyl polyglycol ether (added The average molecular weight of 2400);

[0036] A-6: Allyl polyglycol ether (added The average molecular weight of 5000);

[0037] A-7: Allyl polyglycol ether (added The average molecular weight of 2000, The average molecular weight of 400);

[0038] A-8: Allyl polyglycol ether (added The average molecular weight of 1000, The average molecular weight of 1400);

[0039] Monomer B used in the ...

Embodiment 1

[0041] Add 25.4gA-1 and 63.5gA-2 into a 500ml four-neck flask equipped with devices such as stirring, temperature controller, and raw material dropping, and add 100g of deionized water at the same time, stir and dissolve while heating, and raise the temperature to 55±2°C. After the monomer A is dissolved, add 0.005g of ferrous sulfate and 0.3g of 35% hydrogen peroxide. At 55±2°C, add acrylic acid solution (20g acrylic acid dissolved in 5g water) and sodium ascorbate solution (0.4g sodium ascorbate dissolved in 30g deionized water) dropwise at the same time, the dropping time is controlled at 4 hours, and the reaction temperature remains unchanged . After the dropwise addition, continue to keep warm for 30 minutes, then cool to below 40°C, add sodium hydroxide to neutralize to pH=6.8, add water to dilute to 40%, and obtain a colorless transparent solution. After testing, the average molecular weight is 48000, and the density is 1.06g / ml.

Embodiment 2

[0043]Add 35.3gA-2 and 53.5gA-4 into a 500ml four-neck flask equipped with devices such as stirring, temperature controller, and raw material dropping, and add 100g of deionized water at the same time, stir and dissolve while heating, and raise the temperature to 60±2°C. After the monomer A is dissolved, add 0.006g of ferrous sulfate and 0.3g of 35% hydrogen peroxide. At 60±2°C, add acrylic acid solution (20g acrylic acid dissolved in 5g water) and sodium ascorbate solution (0.4g sodium ascorbate dissolved in 30g deionized water) dropwise at the same time, the dropping time is controlled at 4 hours, and the reaction temperature remains unchanged . After the dropwise addition, continue to keep warm for 30 minutes, then cool to below 40°C, add sodium hydroxide to neutralize to pH=6.8, add water to dilute to 40%, and obtain a colorless transparent solution. After testing, the average molecular weight is 45000, and the density is 1.06g / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com