A method used for assembling bamboo battens of decoration plate

A processing method and technology for decorative panels, which are applied in dovetail tenon processing, wood processing appliances, manufacturing tools, etc., can solve the problems of high production cost, deformation, complicated production process, etc., and achieve the effect of reducing production cost and simplifying production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Concrete process of the present invention is as follows:

[0011] 1. The raw bamboo is punched into strips (including slices and blocks), and the outer layer is removed after the surface is roughened.

[0012] 2. Carbonizing, bleaching, antiseptic treatment and drying the bamboo strips (including slices and blocks) to keep the moisture content below 15%.

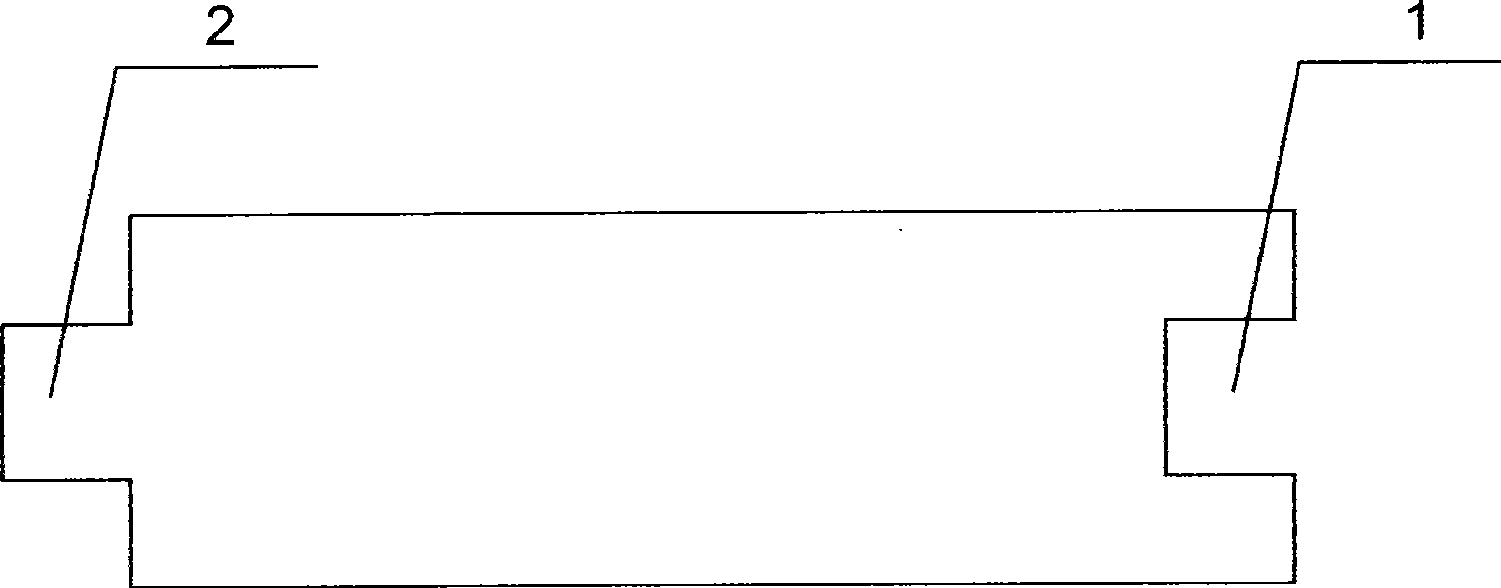

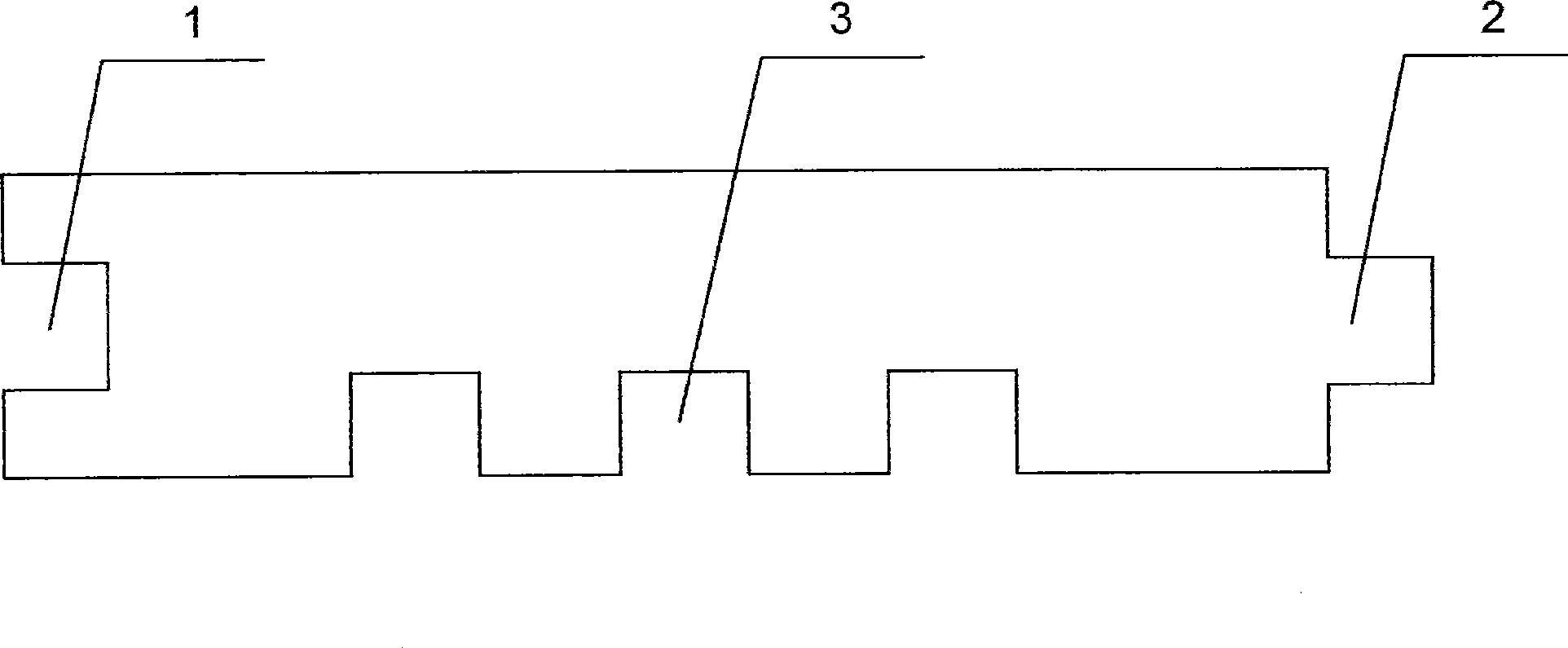

[0013] 3. Finishing the bamboo strips into figure 1 , figure 2 The assembly strip shown has a thickness of 5 to 8 mm and a width of 15 to 30 mm, with a female tenon 1 and a male tenon 2, the thickness and length of the male tenon 2 are 2 to 4 mm, and the female tenon 1 coincides with the male tenon 2, and then in the length direction, at intervals of 5 to 20 cm, several through-crossing grooves 3 are opened, the groove width is between 0.5 and 2 mm, and the groove depth is between 1 and 6 mm. , whose main function is to reduce stress.

[0014] 4. Polish the surface of bamboo strips (including slices and blocks) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com