Method for preparing sodium aluminum hydride

A technology of sodium aluminum hydride and hydrogen, applied in chemical instruments and methods, metal hydrides, inorganic chemistry, etc., can solve the problems of cumbersome steps and not suitable for mass production, and achieve the effect of fewer reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

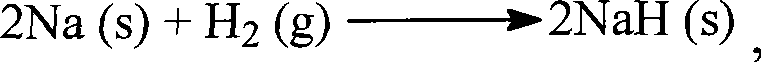

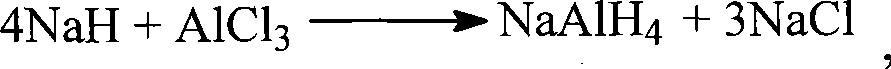

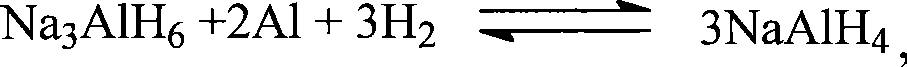

Method used

Image

Examples

Embodiment 1

[0030] First, purify the reaction system with nitrogen, add 40 kg of toluene, 13 kg of aluminum powder, 1000 ppm (part per million) of titanium in 13 kg of aluminum powder, and 0.5 kg of TEA (triethylaluminum). Stir and heat to 110 degrees (°C), add 10 kg of molten sodium, continue heating to 130 degrees, feed hydrogen to pressurize the reactor to 15168KPa, and continue the reaction for 2.5 hours. During the reaction, control the reaction temperature at 135 degrees and the pressure at 15168KPa. The exhaust was cooled to room temperature. Settling and discharging the upper layer toluene clear liquid, then washing with toluene, settling and discharging the upper layer toluene clear liquid, drying to obtain sodium aluminum hydride solid. The conversion of sodium aluminum hydride on a sodium basis was 98%.

Embodiment 2

[0032] First purify the reaction system with nitrogen, add 40 kg of toluene, 13 kg of aluminum powder, 1000 ppm of titanium and 0.5 kg of TEA in the 60 liter autoclave equipped with agitator and cooling coil. Stir and heat to 110°C, add 10 kg of molten sodium, continue heating to 130°C, feed hydrogen to pressurize the reactor to 15168KPa, and continue the reaction for 2.8 hours. During the reaction, control the reaction temperature at 130°C and the pressure at 15168KPa. The exhaust was cooled to room temperature. Settling and discharging the upper layer toluene clear liquid, then washing with toluene, settling and discharging the upper layer toluene clear liquid, drying to obtain sodium aluminum hydride solid. The conversion of sodium aluminum hydride on a sodium basis was 96%.

Embodiment 3

[0034] First purify the reaction system with nitrogen, add 40 kg of toluene, 13 kg of aluminum powder, 1000 ppm of titanium and 0.5 kg of TEA in the 60 liter autoclave equipped with agitator and cooling coil. Stir and heat to 110°C, add 10 kg of molten sodium, continue heating to 130°C, feed hydrogen to pressurize the reactor to 15168KPa, and continue the reaction for 2.2 hours. During the reaction, control the reaction temperature at 145°C and the pressure at 15168KPa. The exhaust was cooled to room temperature. Settling and discharging the upper layer toluene clear liquid, then washing with toluene, settling and discharging the upper layer toluene clear liquid, drying to obtain sodium aluminum hydride solid. The conversion of sodium aluminum hydride on a sodium basis was 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com