Anaerobic fermentation technical method of septic tank sediments by assist of industrial waste heat

A technology of anaerobic fermentation and process method, which is applied in the direction of waste fuel, climate change adaptation, solid waste removal, etc., can solve the problems of no suitable, etc., and achieve the effects of reducing emissions, advancing gas production time, and shortening the degradation cycle

Inactive Publication Date: 2010-11-10

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There is no suitable equipment for anaerobic fermentation of high-concentration septic tank sediments

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

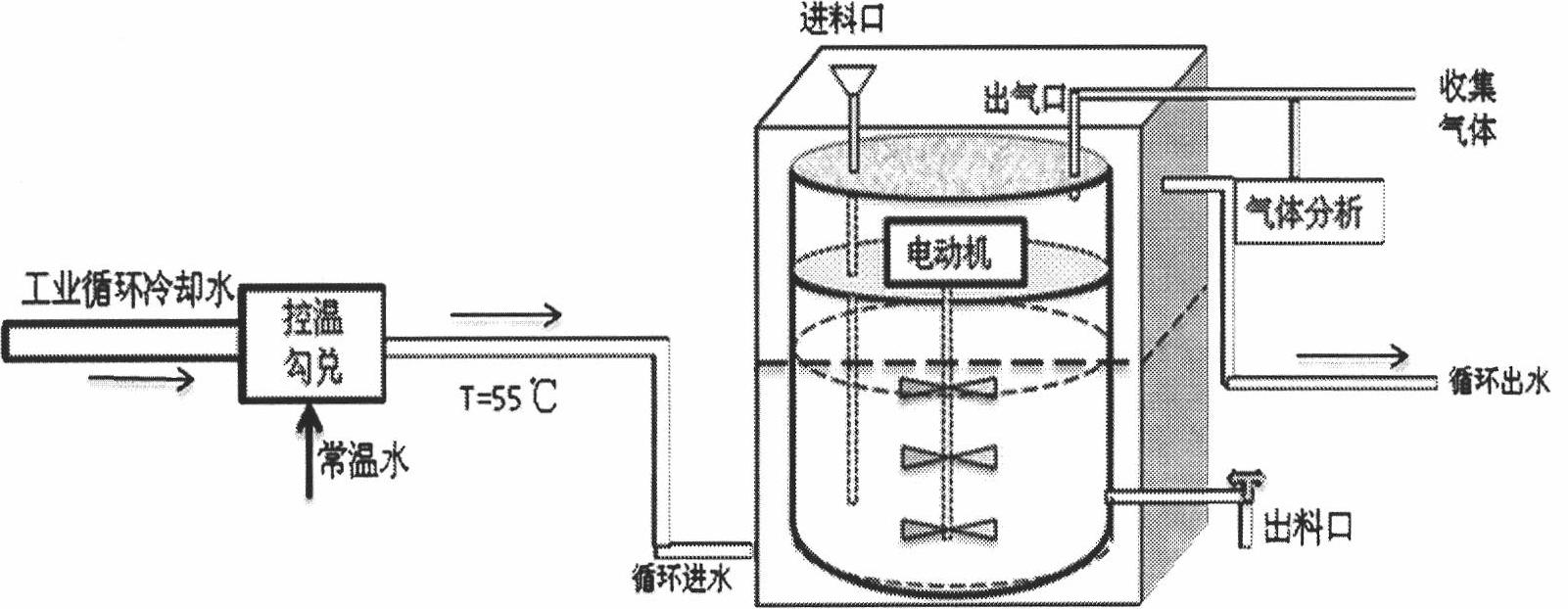

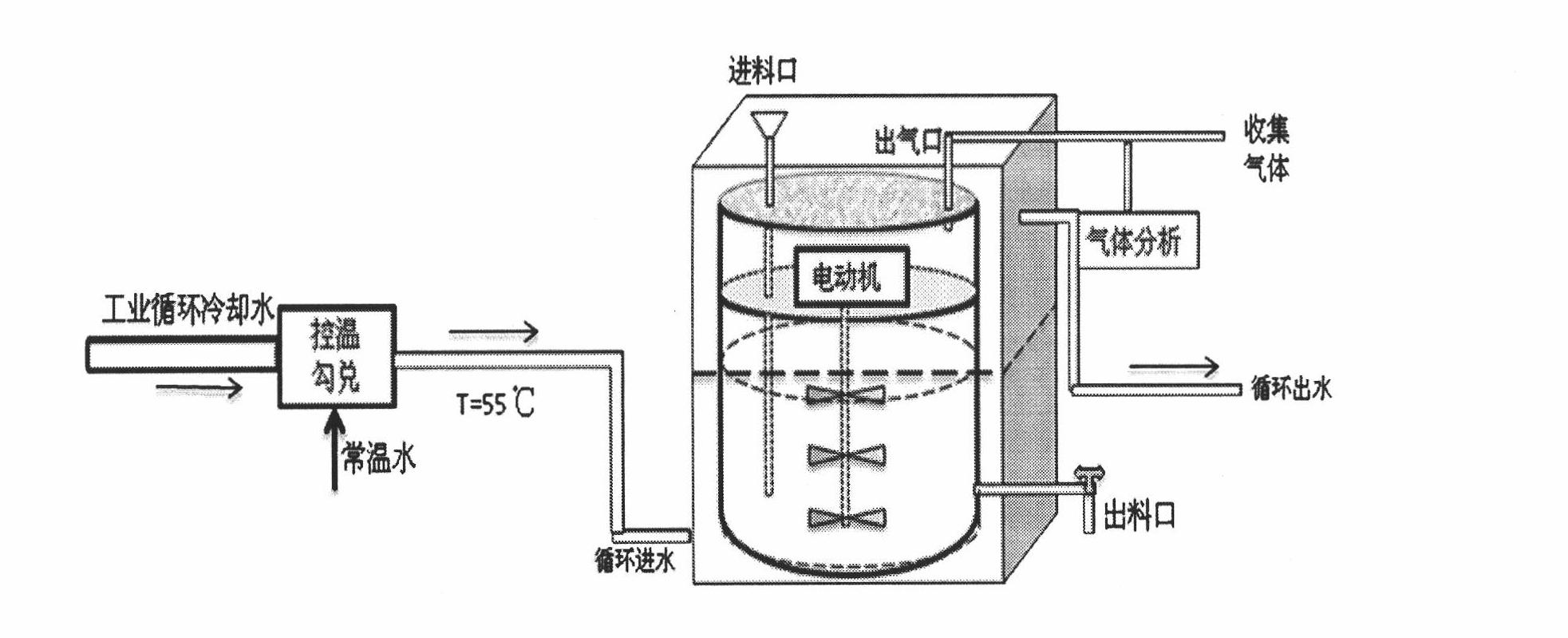

The invention provides an anaerobic fermentation technical method of septic tank sediments under the assist of industrial waste heat, belonging to the technical field of an environment-friendly energy. The invention is characterized in that the method comprises the following steps of: taking septic tank sediments as a raw material under the condition that the temperature provided by the industrial waste heat is 55 DEG C; adding liquid dung which is adjusted to ensure that pH=7.2-7.4 and Ts=8%-10% into an anaerobic fermentation pot; stirring and fermenting the mixture; when enriched strains meet the condition that fermentation pot operates at the full load, normally generating gas; stopping stirring before fermentation gas generation reaches an inflection point at each time; extracting 2 / 3fermenting fluid to produce fertilizer, fermenting the remaining 1 / 3 fermenting fluid to generate marsh gas; rinsing, desulfurizing, drying and storing the marsh gas in a canning way after the marsh gas enters into a marsh gas collecting tower. The invention can advance gas generating time, lift gas-generating efficiency, shorten degradation period, achieve a recycling effect since marsh residuesand marsh liquid can be made into fertilizer and biotic pesticide with high quality, and simultaneously reduce sewage discharge to achieve a minimizing effect.

Description

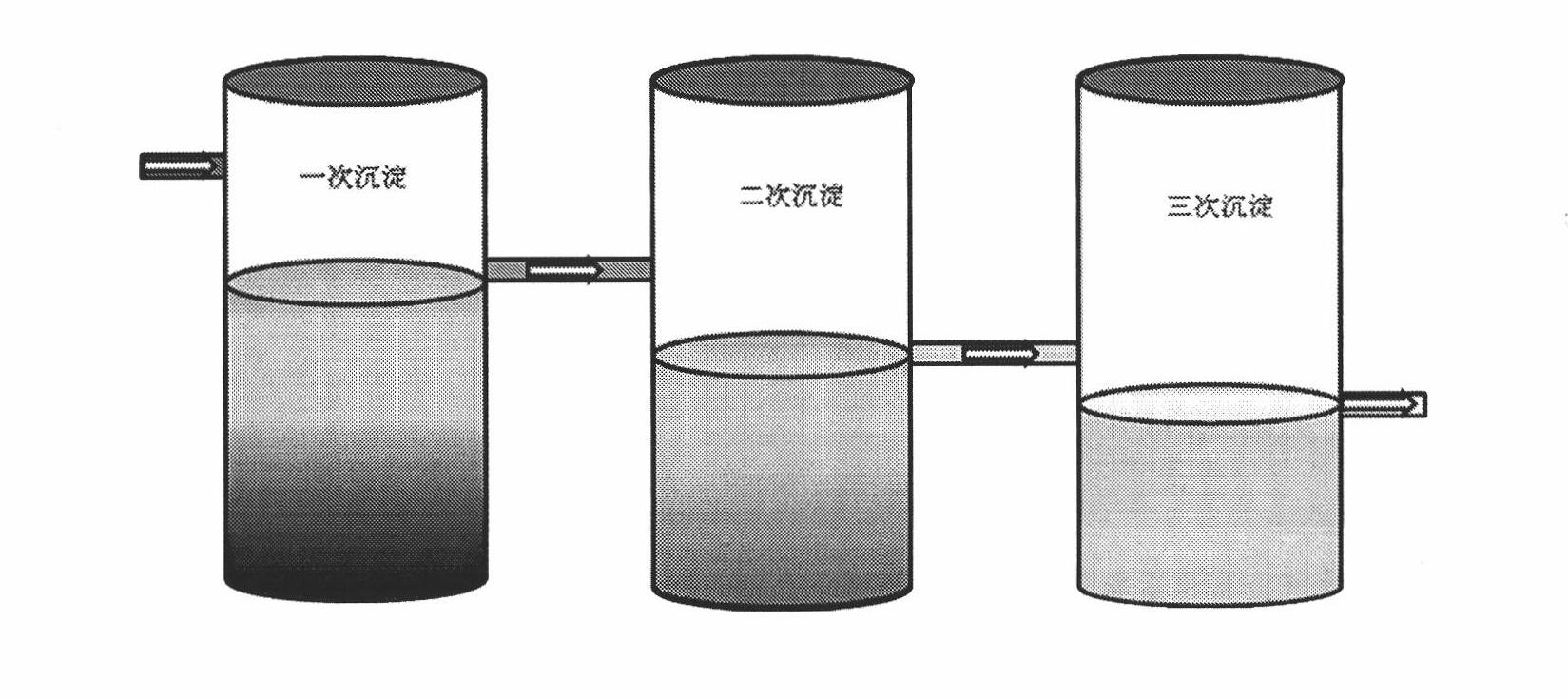

A process method for anaerobic fermentation of septic tank sediments assisted by industrial waste heat technical field The invention belongs to the technical field of environmental protection energy, and relates to a method for producing biogas by high-temperature anaerobic fermentation, specifically, a high-temperature anaerobic fermentation using urban septic tank sediments as raw materials and under the temperature conditions provided by industrial waste heat Process methods for producing biogas, biogas slurry and biogas residue. Background technique At present, the discharge from urban toilets enters the septic tanks installed in the building units through pipelines. Its function is to receive and store household sewage. Its internal structure is divided into primary sedimentation tanks, secondary sedimentation tanks and tertiary sedimentation tanks. The principle is to use the different densities of the components of the effluent to carry out graded sedimentation: the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B09B3/00

CPCY02E50/343Y02A40/20Y02E50/30Y02P20/129Y02W10/20Y02W30/40

Inventor 苍大强董建白皓宗燕兵陈相利赵立华张玲玲赵洁玉刘维顺王雪婷

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com