Polyacetal resin composition

一种聚缩醛树脂、组合物的技术,应用在聚缩醛树脂组合物领域,能够解决很难耐候性外观、热稳定性或耐光性降低、加成性不成立等问题,达到耐候(光)性优异、抑制氧化分解、抑制解聚的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

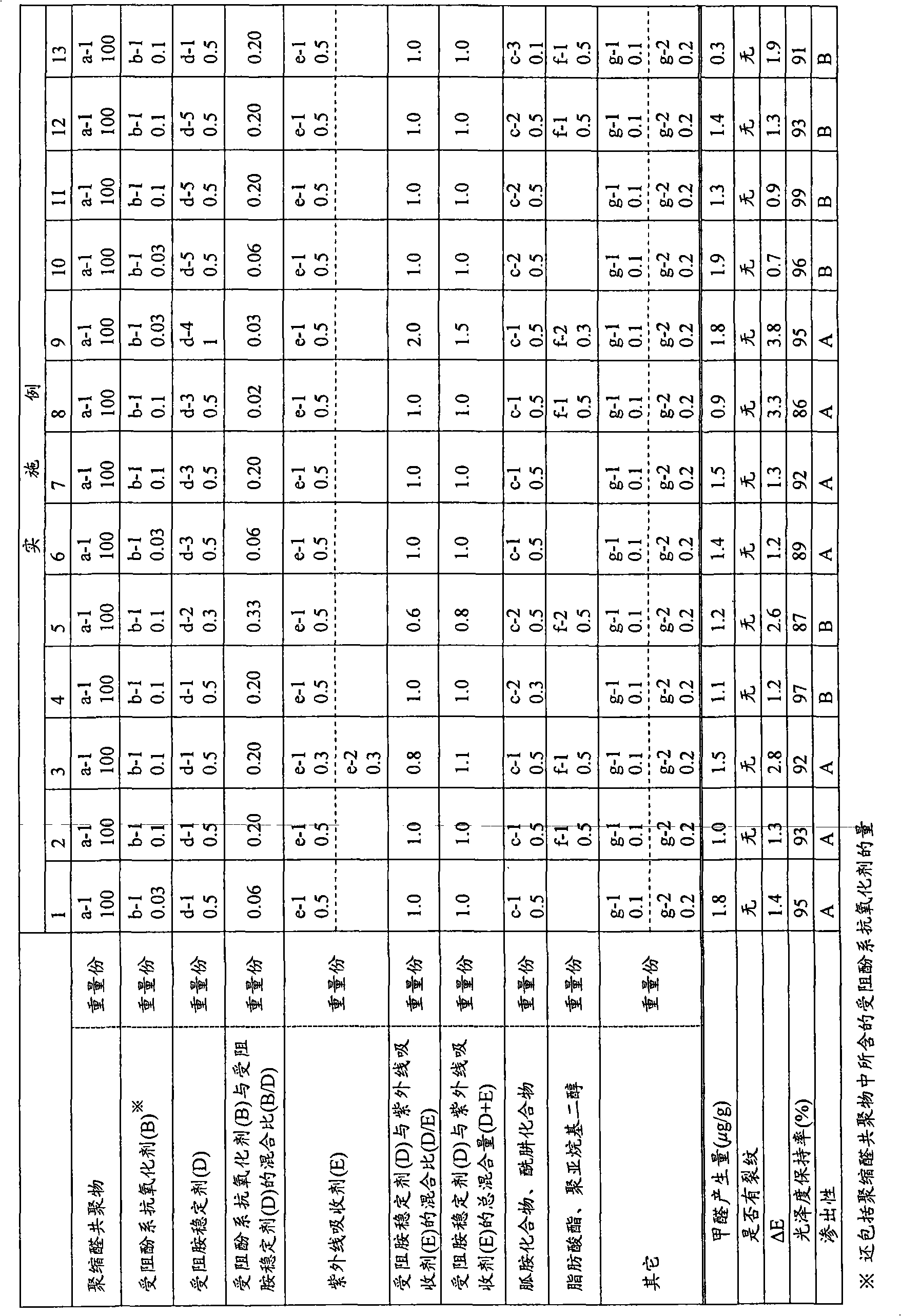

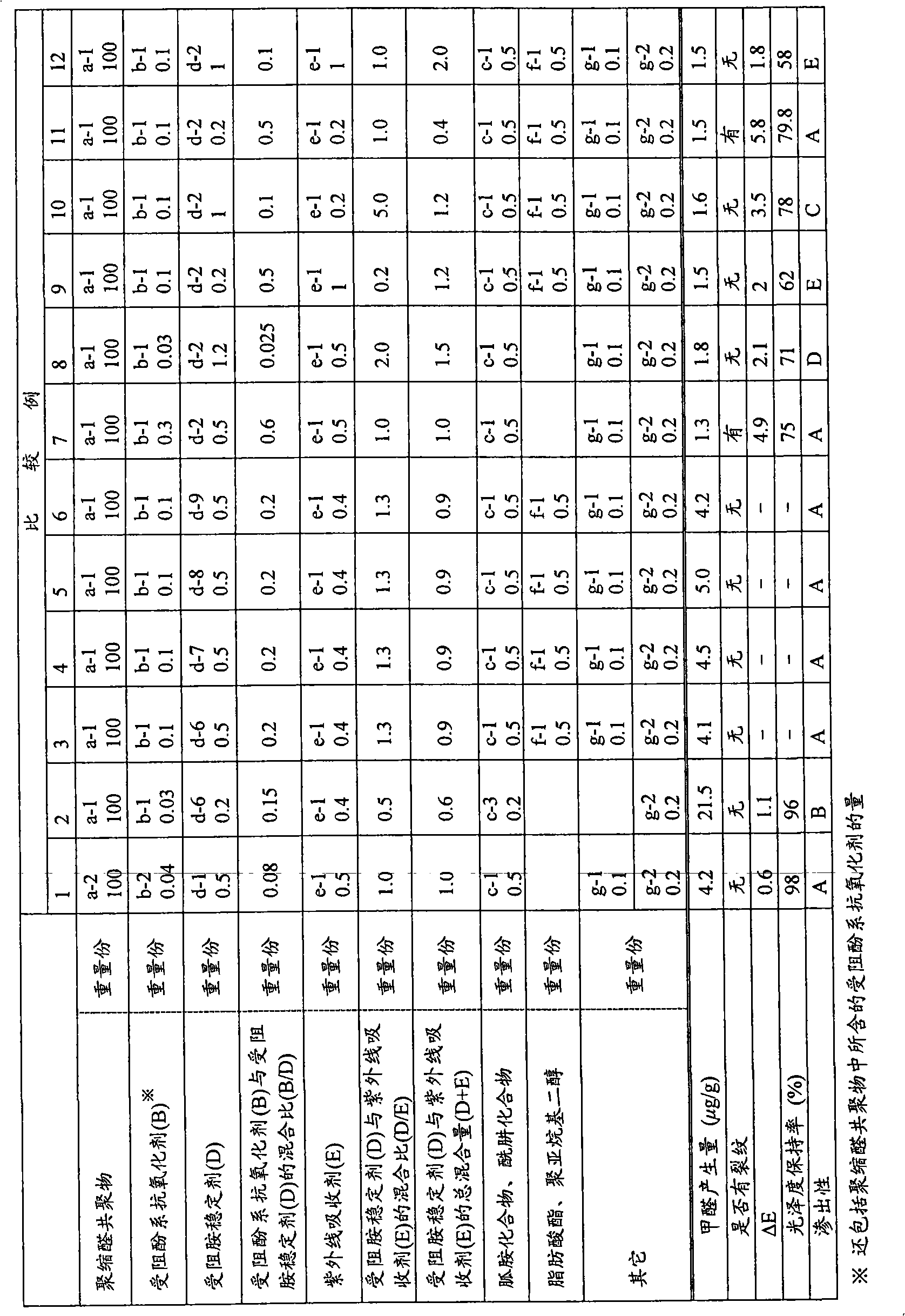

[0136] In accordance with the ratio shown in Table 1, hindered phenol antioxidants, guanamine compounds, and piperidine derivatives whose nitrogen is a tertiary nitrogen hindered amine stabilizer, ultraviolet absorber, fatty acid formed from fatty acid and polyalkylene glycol Ester, polyalkylene glycol, and other compounds are premixed with 100 parts by weight of polyacetal copolymer with specific polymer quality indicators, and then put into a twin-screw extruder with a vent and a diameter of 30 mm The main feed port is melted and mixed (extrusion conditions: L / D=35, extrusion temperature=200°C, screw rotation=120rpm, exhaust vacuum=-700mmHg, output=18kg / hour) to prepare pellets状的Composition. In addition, for weathering (light) resistance and exudation evaluation, 0.3 parts by weight of the pigment (iron iron) and 100 parts by weight of the granular composition were mixed, and then put into a double vent with a diameter of 30 mm. The main feed port of the screw extruder is melted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com