Pigment composition for color filter

A pigment composition and color filter technology, which is applied in the direction of instruments, optical filters, organic dyes, etc., can solve the problems of uneven coating, insufficient light transmittance, insufficient brightness and contrast of color filters, etc. bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

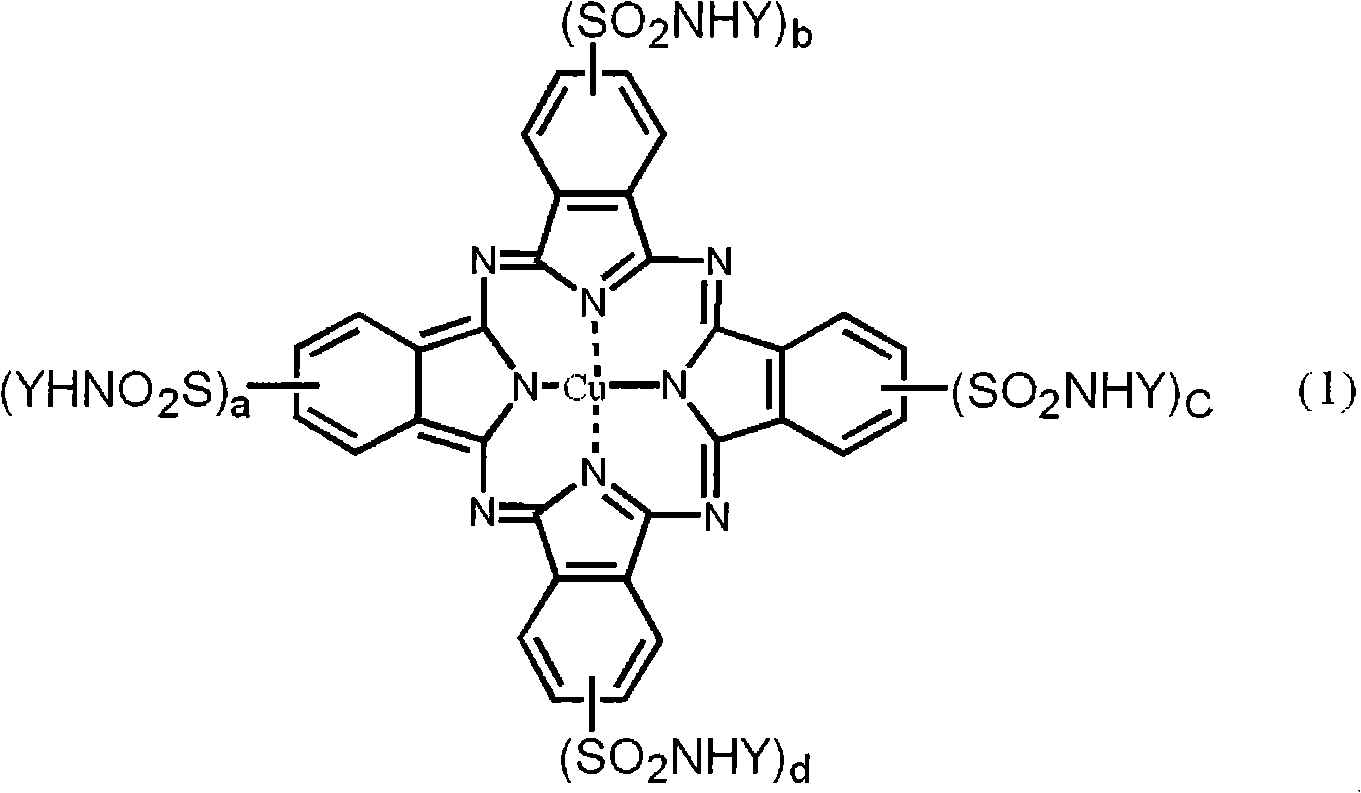

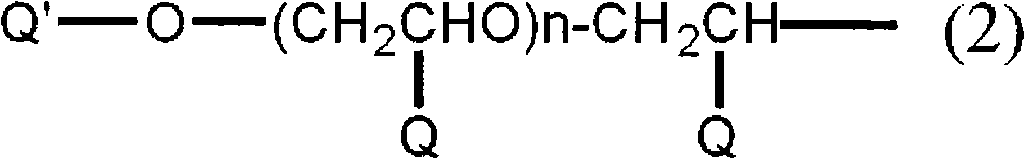

[0091] "Surfonamine B-200" (trade name) (primary amine-terminal poly(ethylene oxide / propylene oxide) (5 / 95) copolymer, number average In the mixture of molecular weight about 2000), 66 parts of sodium carbonate and 150 parts of water, add 210 parts of copper phthalocyanine sulfonyl chloride (sulfonation degree=1), react at 5 ℃~room temperature for 6 hours. The obtained reaction mixture was heated to 90° C. under vacuum to remove water, and a copper phthalocyanine sulfamoyl compound (S1) was obtained.

manufacture example 2~16

[0093] Copper phthalocyanine sulfamoyl compounds (S2) to (S16) were obtained in the same manner as in Production Example 1 except that the raw materials used were the combinations described in Table 1. Also, in Production Example 12, UNILUBE 20MT-2000B (trade name, manufactured by NOF Corporation), which is a monoalkyl polyether having a branched C24 hydrocarbon group, was converted into a polyether monoamine by reductive amination reaction.

[0094] Table 1

[0095]

[0096]

[0097] The color filter was manufactured by the following method, and the evaluation result is shown in Table 2.

[0098] [Manufacturing method of color filter for test]

Embodiment 1

[0100] Copper phthalocyanine sulfamoyl compound (S1) represented by general formula (1) obtained in 3.0 parts of manufacture example 1, 10.0 parts of ε type copper phthalocyanine pigment (pigment blue 15:6, the product of average primary particle diameter 50nm ), 0.20 parts of FASTOGEN SUPER VIOLET RVS (trade name: manufactured by Dainippon Ink Industry Co., Ltd., Pigment Violet 23), and 49 parts of propylene glycol monomethyl ether acetate, add 0.5mmΦ ceramic beads (sepr beads), and adjust with paint (manufactured by Toyo Seiki Co., Ltd.) for 2 hours to obtain a blue pigment dispersion. 75.00 parts of the blue pigment dispersion, 5.50 parts of polyester acrylate resin (ARONIX M7100, manufactured by Toa Gosei Chemical Industry Co., Ltd.), 5.00 parts of dipentaerythritol hexaacrylate (KAYARAD DPHA, manufactured by Nippon Kayaku Co., Ltd.) were stirred with a dispersing mixer. ), 1.00 parts of benzophenone (KAYACURE BP-100, manufactured by Nippon Kayaku Co., Ltd.), and 13.5 part...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap