Nuclear engineering plant and method for operating a nuclear engineering plant

A nuclear technology and degassing device technology, applied in the field of degassing devices, can solve problems such as design and size are no longer sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

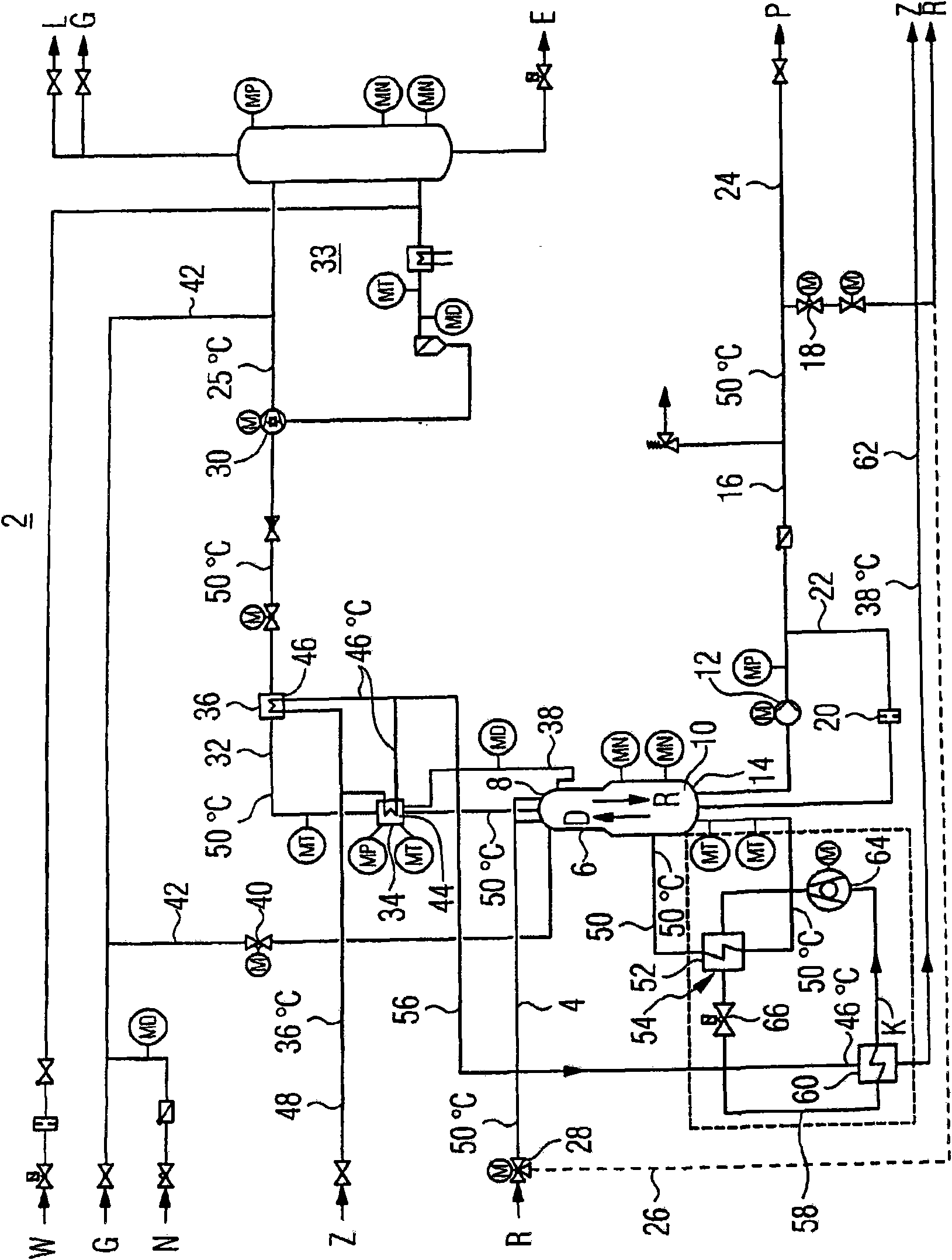

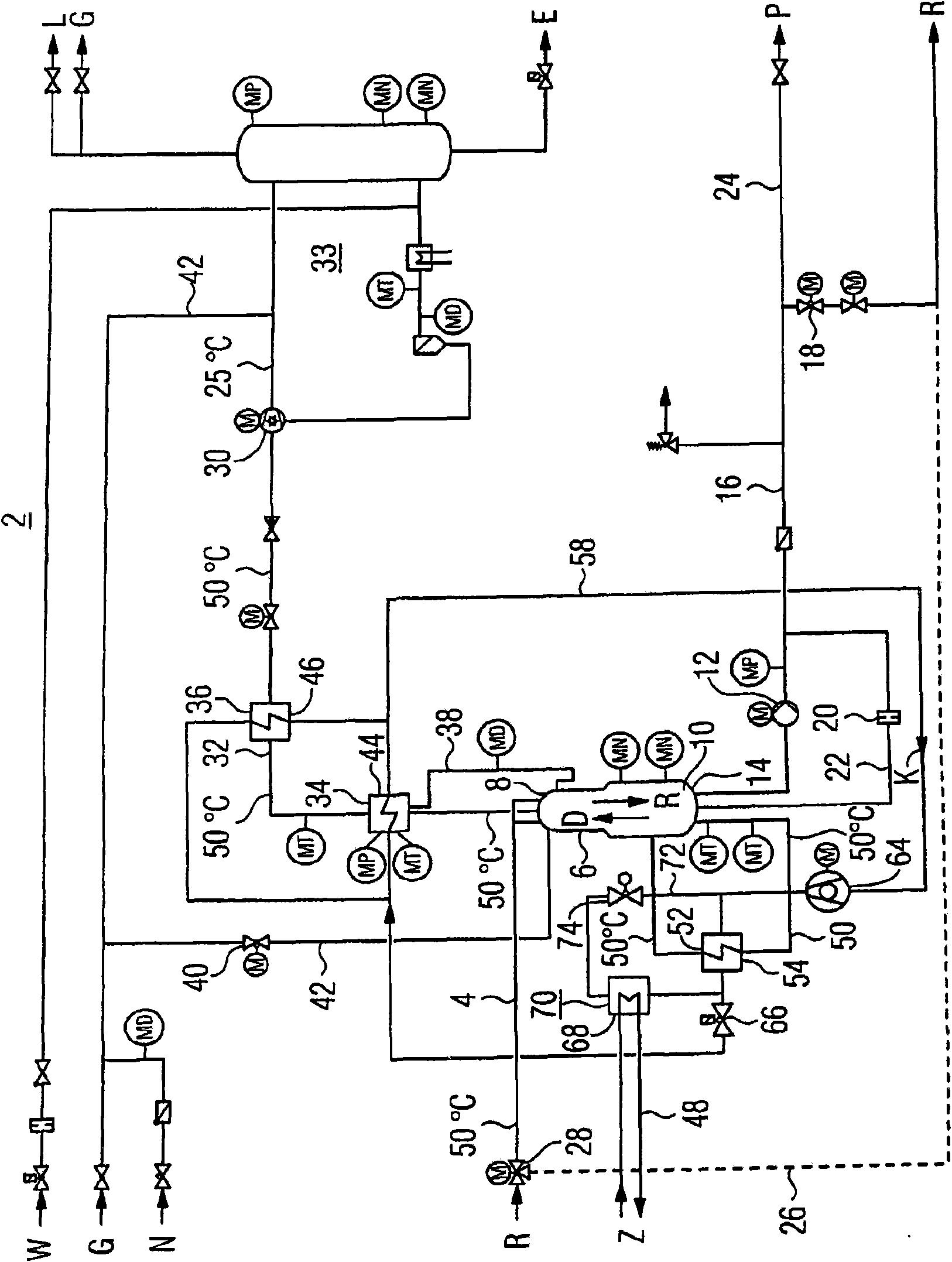

[0045] exist figure 1 The degassing device 2 for the reactor coolant R shown in the simplified circuit diagram together with some peripheral components comprises a degassing device 2 supplied from the main circuit of the pressurized water reactor with the gas-containing reactor coolant R through the coolant input pipe 4. Gas tower 6. The gas-containing reactor coolant R enters the degassing tower 6 at an inlet temperature of about 50°C through the coolant input pipe 4 connected to the tower top 8 during the operation of the device 2, and the degassing tower 6 is filled with about 0.125 The operating pressure of bar corresponds approximately to the boiling point temperature, followed by a plurality of blister bottoms not further shown here ( ) is sprayed downward and finally collected in the tower pool tank 10 of the degassing tower 6. During downward spraying the reactor coolant R meets in an intensive contact manner the degassing D which is introduced into the degasser 6 ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com