Liquid ejecting head, liquid ejecting apparatus, and actuator

A liquid ejection head and liquid ejection technology, which can be used in printing and other directions to solve problems such as the destruction of the taper portion of the piezoelectric layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

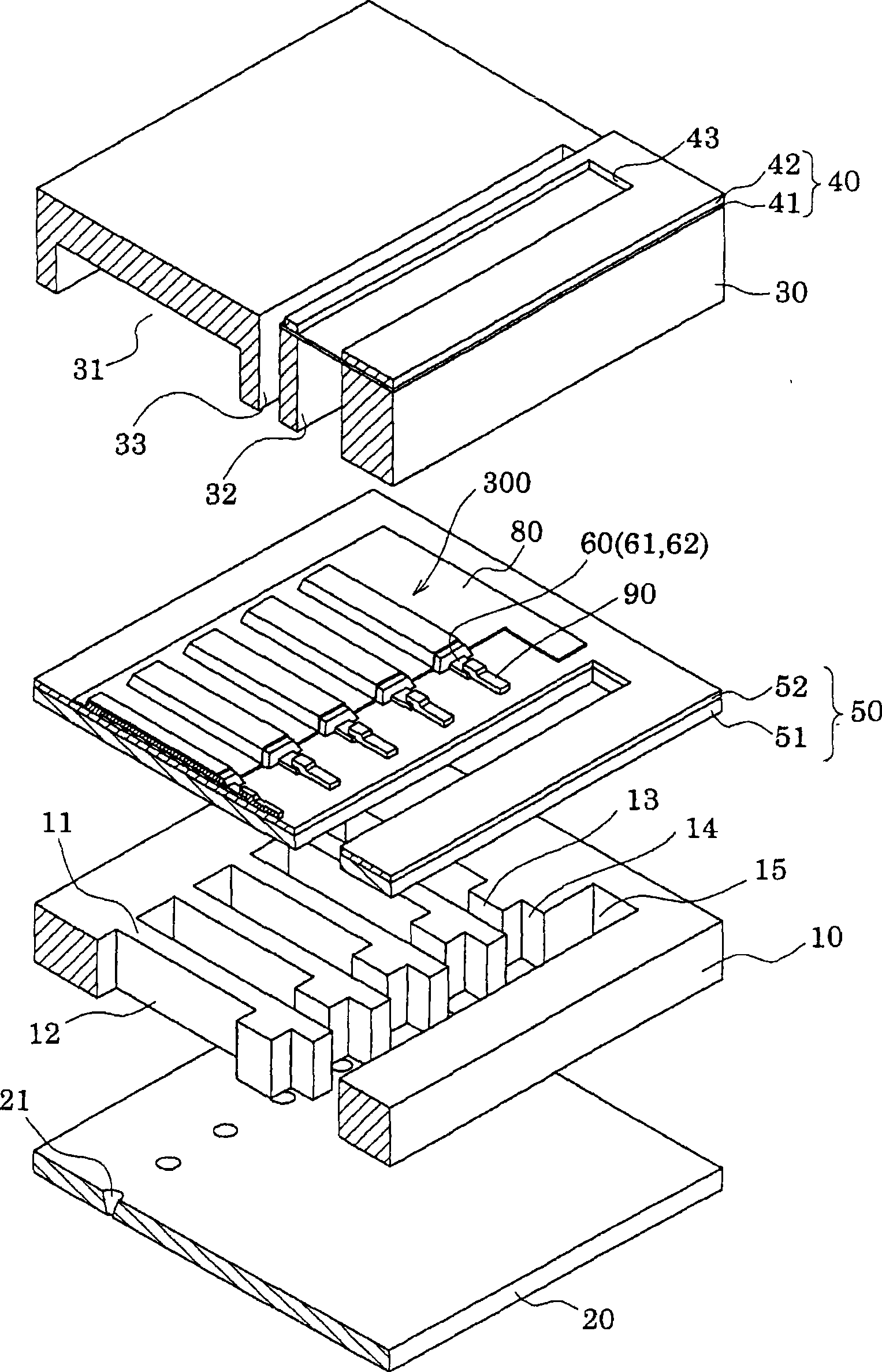

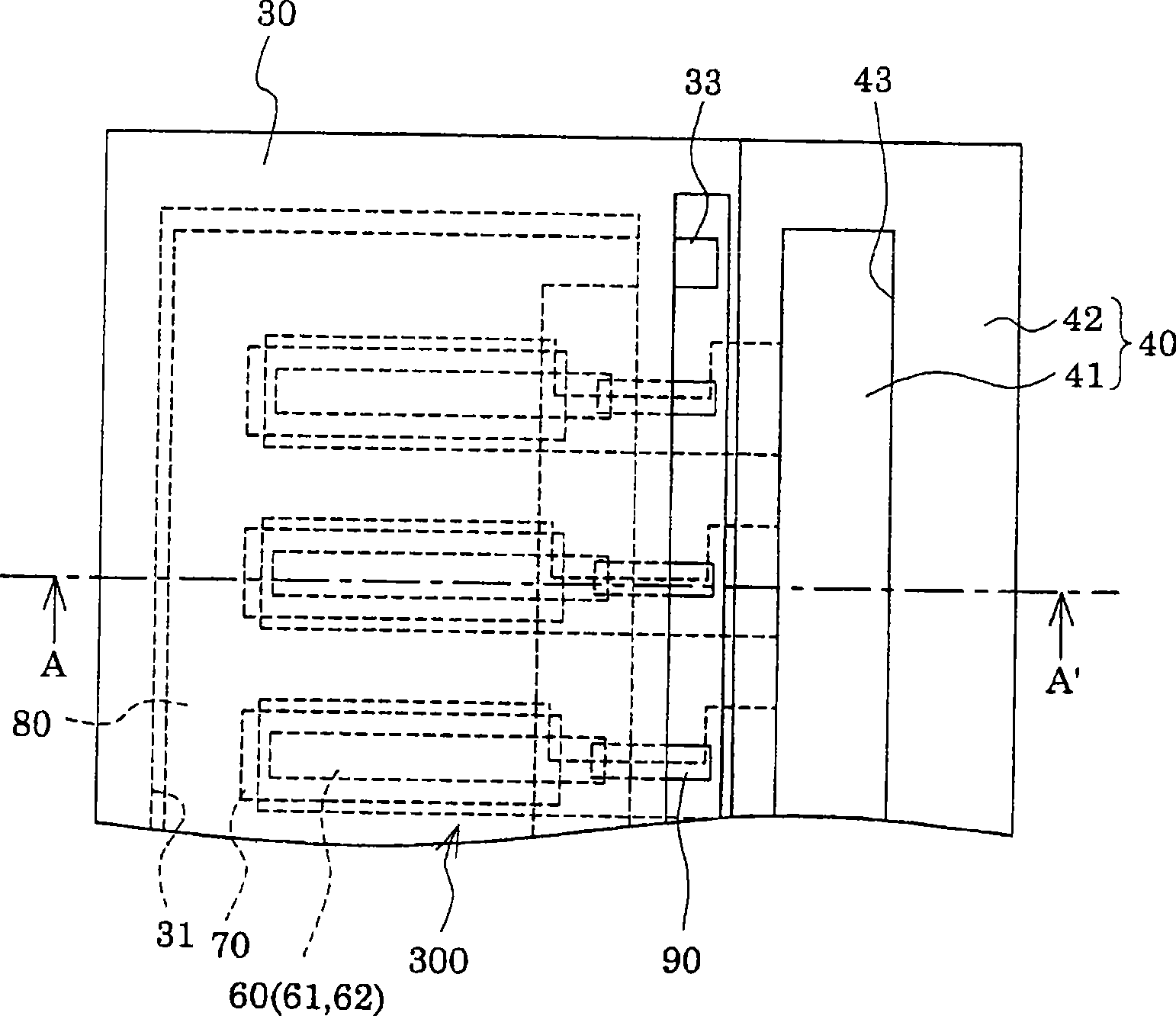

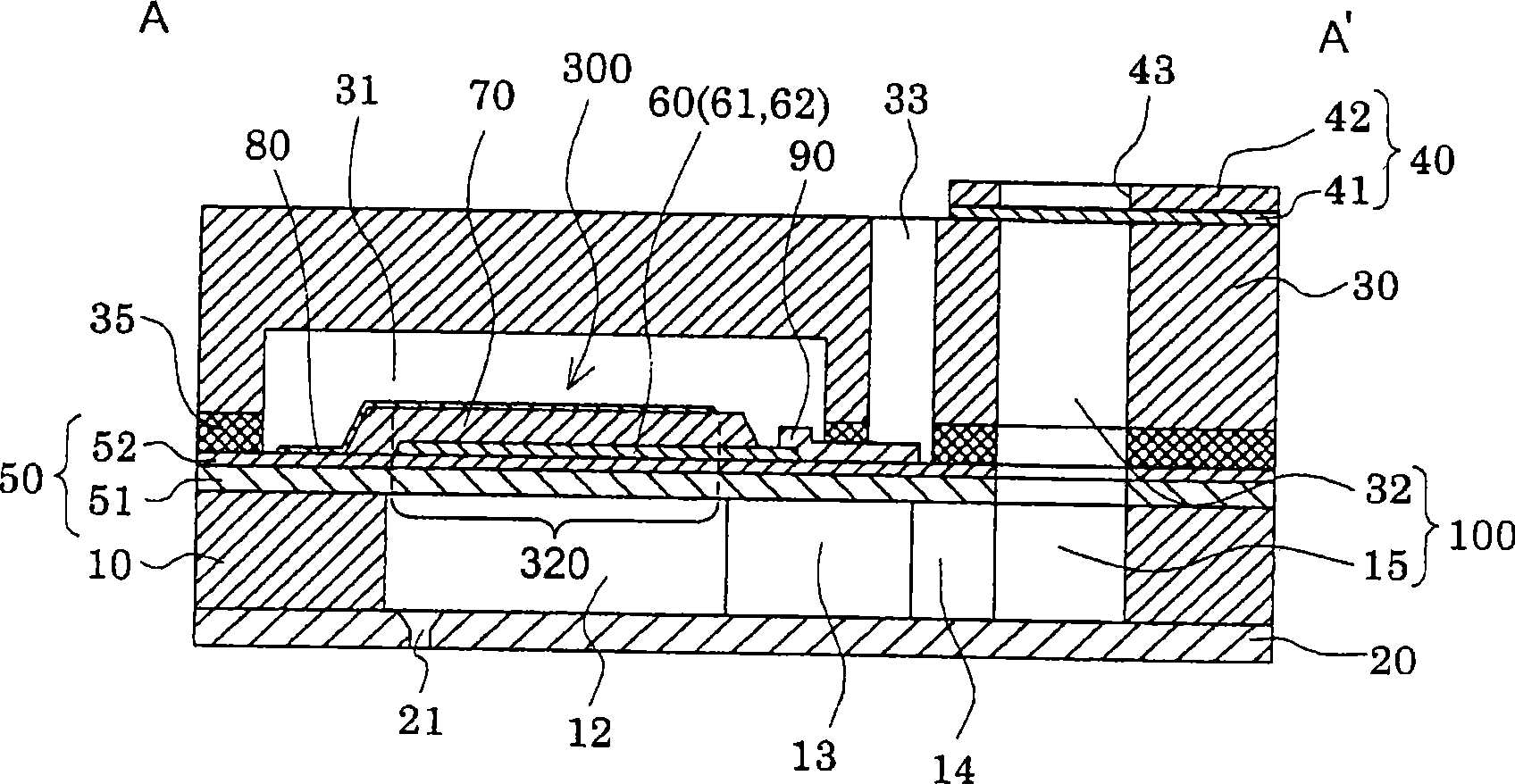

[0041] figure 1 It is an exploded perspective view showing a schematic structure of an ink jet recording head which is an example of the liquid ejecting head according to Embodiment 1 of the present invention, Figure 2A and Figure 2B respectively figure 1 The plan view and the A-A' sectional view of the plan view.

[0042] As shown in the figure, the channel forming substrate 10 is formed of a single crystal silicon substrate having a crystal plane direction of (110) in this embodiment, and an elastic film 51 made of an oxide film is formed on one surface thereof. On the flow path forming substrate 10 , a plurality of pressure generating chambers 12 divided by the partition wall 11 and having one surface formed of an elastic film 51 are arranged side by side in the width direction thereof.

[0043] On one end side in the longitudinal direction of the pressure generating chambers 12 on the flow path forming substrate 10 , an ink supply passage 13 and a communication path 1...

Embodiment approach 2

[0084] Figure 8 It is a cross-sectional view showing main parts of the ink jet recording head according to the second embodiment.

[0085] This embodiment is another example of the structure of the lower electrode film, and the structure other than the lower electrode film 60 is the same as that of the first embodiment. That is, compared to the formation of the orientation control layer 62 on the conductive layer 61 (upper surface) in Embodiment 1, as Figure 8 As shown, in this embodiment, the orientation control layer 62A constituting the lower electrode film 60 is provided on the upper surface and the end surface of the conductive layer 61 , that is, the orientation control layer 62A is provided to cover the conductive layer 61 .

[0086] With such a structure, since piezoelectric layer 70 is formed on orientation control layer 62A also at the end surface of lower electrode film 60 , the crystallinity of piezoelectric layer 70 near the end of lower electrode film 60 is fu...

Embodiment approach 3

[0088] Figure 9 is an exploded perspective view showing a schematic configuration of an ink jet recording head according to Embodiment 3, Figure 10A and Figure 10B respectively Figure 9 and the BB' section of the plan. in addition, Figure 11 It is a cross-sectional view showing main parts of the ink jet recording head according to the third embodiment. for with Figure 1 ~ Figure 3 Components that are the same as those shown are assigned the same reference numerals and repeated explanations are omitted.

[0089] This embodiment is the same as Embodiment 1 except that the common electrode of the piezoelectric element 300 is formed of the lower electrode film 60A constituting the piezoelectric element 300 and the dedicated electrode is formed of the upper electrode film 80A.

[0090] As shown in the figure, the lower electrode film 60A of the present embodiment is provided on each area opposite to each pressure generating chamber 12 with a width narrower than that of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com