An alumina ink-jet coating and a manufacturing method thereof

A technology of alumina and manufacturing method, applied in the direction of copying/marking method, printing, etc., can solve the problems of rising production cost, low weather resistance of images, and high brittleness of the coating, and achieves improved color density, high gloss, and good weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be described in further detail below in conjunction with specific embodiments:

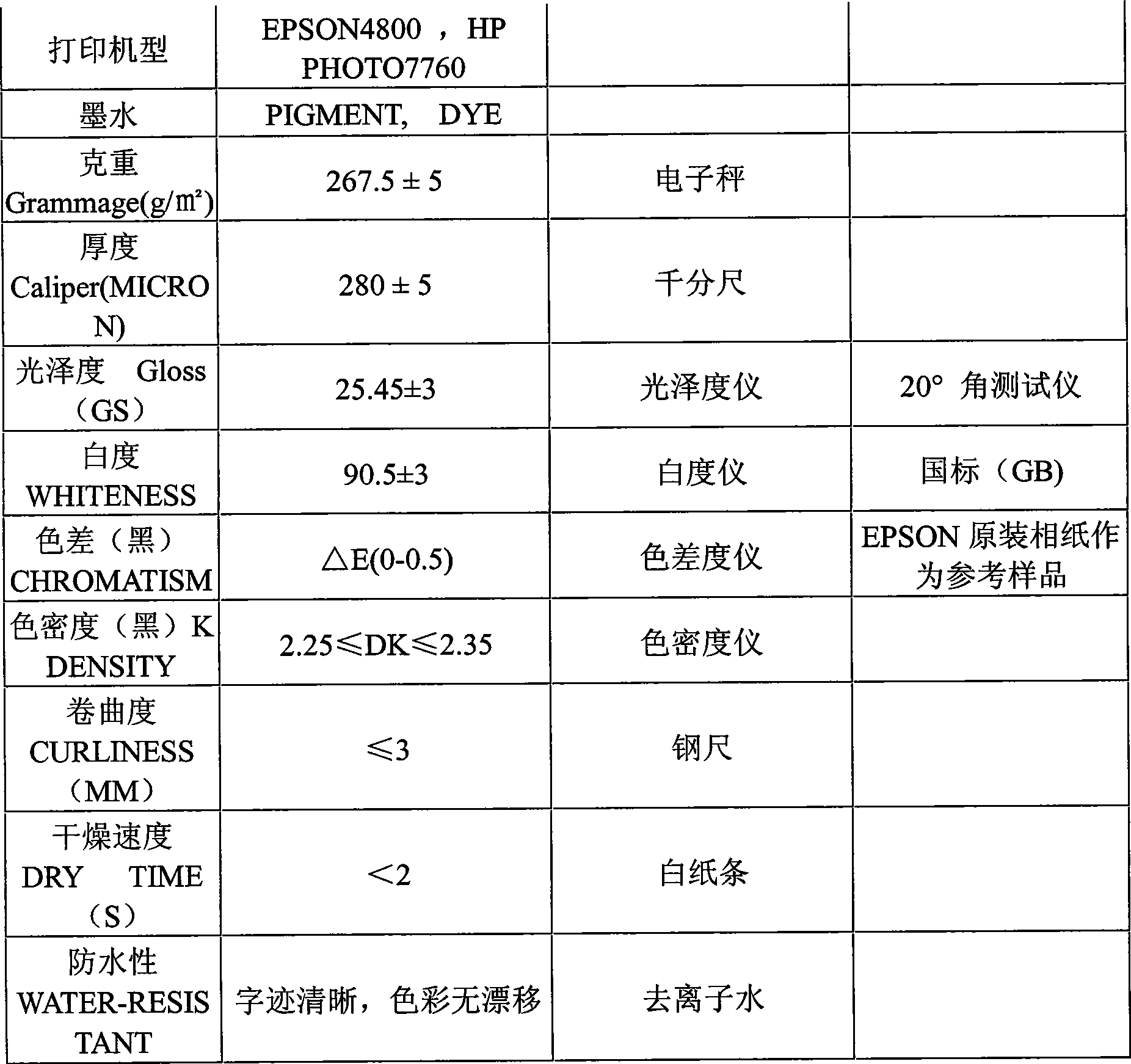

[0020] This embodiment discloses a kind of aluminum oxide ink-jet coating, which can be coated on the paper base to form an ink-jet coating. According to the weight ratio, the coating composition is: 20 parts of alumina powder, 76.3 parts of water, 0.3 part of hydrochloric acid, poly 1.8 parts of vinyl alcohol, 0.14 parts of crosslinking agent, 1.45 parts of cationic color fixing agent, and 0.06 parts of surfactant.

[0021] Wherein, the aluminum oxide powder is a nanoscale micropowder with a particle size between 15 and 35 nanometers. By adding hydrochloric acid as the dispersant of nano-scale alumina, the printing color has high color saturation while the dispersion system has good stability; polyvinyl alcohol (can be purchased from KURARAY (Kuraray) company in Japan, its model PVA235) is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com