A boride- nitride complex-phase ceramic and its preparing process

A composite ceramic and preparation technology, applied in the field of inorganic non-metallic material science, can solve the problems of low strength and fracture toughness, which have not been solved well, and achieve the effect of easy acquisition, less process and excellent high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

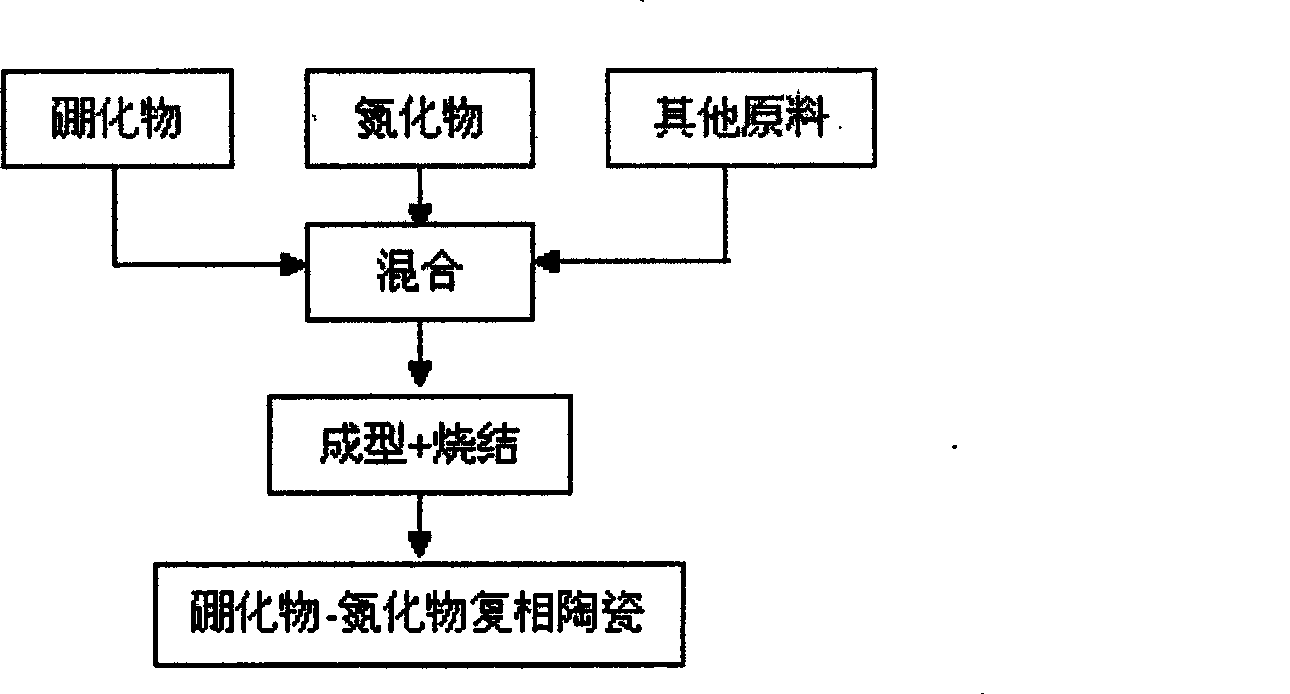

Method used

Image

Examples

Embodiment 1

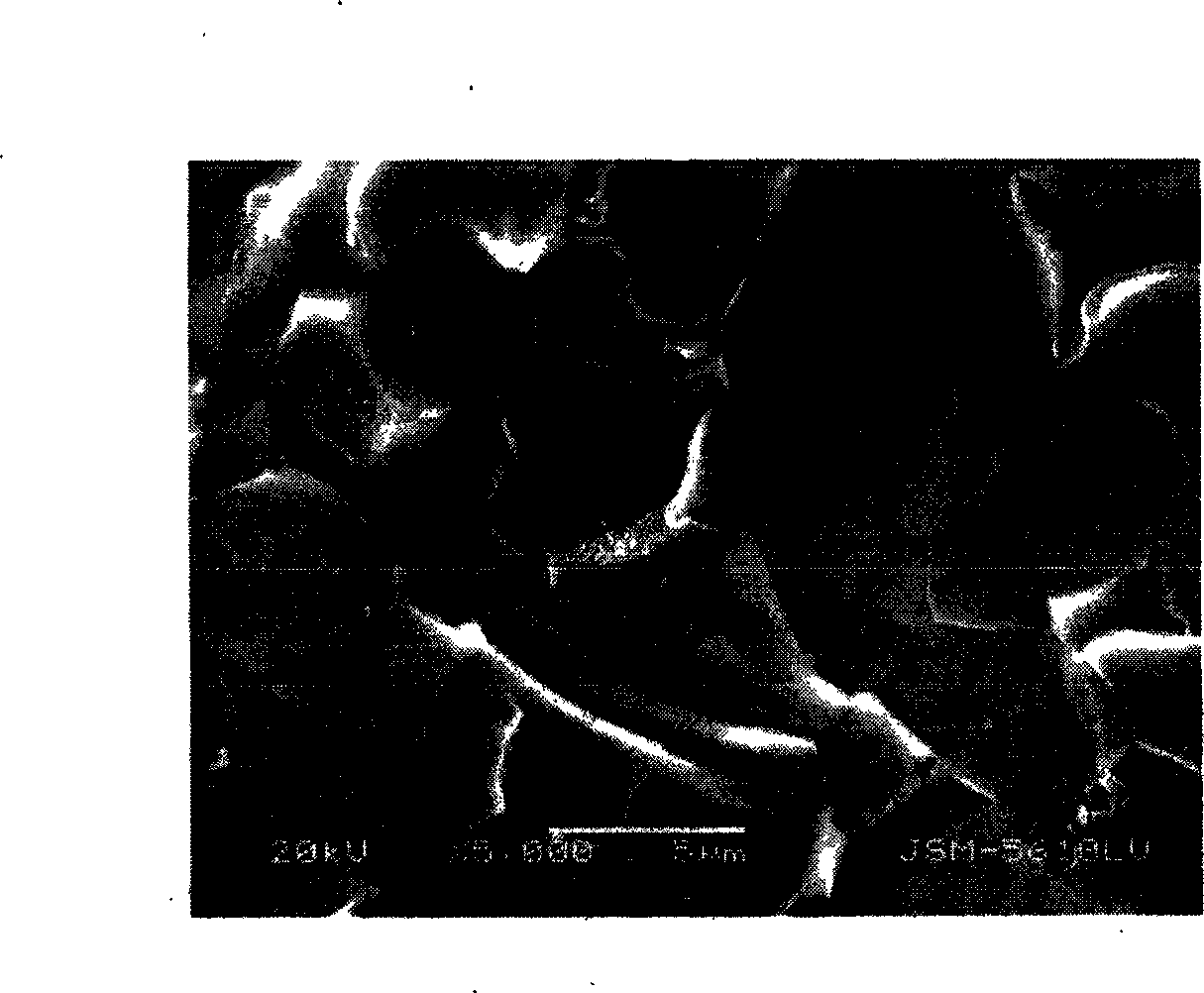

[0020] 8 g ZrB 2 Powder, 1.5g Si 3 N 4 Powder and 0.5g Y 2 o 3 Mix the powder evenly, put it into a graphite mold, press it slightly to form it, put it into a discharge plasma sintering furnace together with the mold, and sinter at 1700°C for 10 minutes under a pressure of 20MPa in a vacuum environment, and cool to room temperature with the furnace. The ceramic block is taken out from the mold, and the surface layer is removed by grinding to obtain a zirconium diboride-silicon nitride composite ceramic with a relative density of more than 96%, and its microstructure is as follows: figure 2 shown.

Embodiment 2

[0022] 7 g ZrB 2 Powder, 2g Si 3 N 4 powder and 1 gram of Y 3 al 5 o 12 Mix the powder evenly, put it into a graphite mold, press it slightly to form it, put it into a discharge plasma sintering furnace together with the mold, and sinter at 1700°C for 6 minutes under a pressure of 20MPa in a vacuum environment, and cool to room temperature with the furnace. The ceramic block is taken out from the mould, and the surface layer is removed by grinding to obtain a zirconium diboride-silicon nitride composite ceramic with a relative density of more than 98%.

Embodiment 3

[0024] 7 g ZrB 2 Powder, 2g Si 3 N 4 powder and 1 gram of Y 3 al 5 o 12 Mix the powder evenly, put it into a graphite mold, put it into a hot-press sintering furnace together with the mold, and sinter at 1850°C for 60 minutes under a pressure of 25MPa in a vacuum environment, cool to room temperature with the furnace, and take the ceramic block out of the mold , and the surface layer is removed by grinding to obtain a zirconium diboride-silicon nitride composite ceramic with a relative density of more than 97%.

[0025] Other sintering temperatures, pressures, times and proportions of various powders can also be selected to prepare high-density boride-nitride composite ceramics in a hot-press or spark plasma sintering furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com