High performance nano powder body-based tread rubber of engineering tire and preparation process thereof

A nano-powder, engineering tire technology, used in special tires, tire parts, transportation and packaging, etc., can solve the problems of immature formula and technology, and achieve the effect of excellent mechanical properties, good wear resistance and puncture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

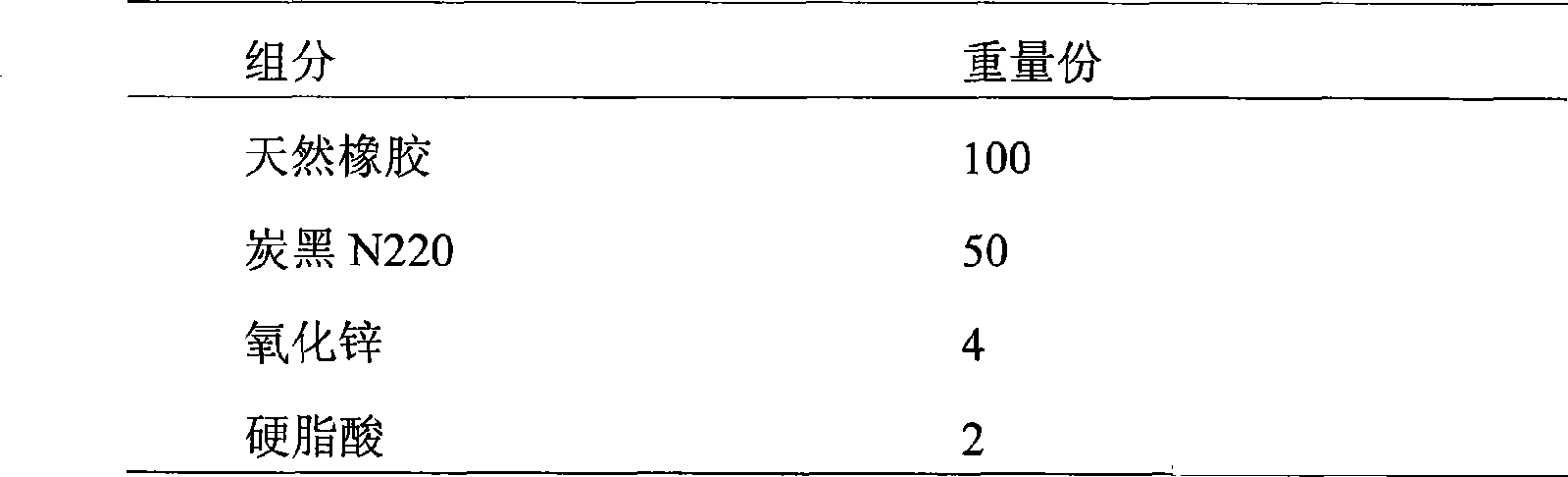

[0018] The high-performance engineered tire tread rubber formula based on nano powder of the present embodiment is:

[0019]

[0020]

[0021] The preparation process of the high-performance engineering tire tread rubber based on nano-powder of the present embodiment is:

[0022] a. Ingredients: Weigh the required quality of various raw materials according to the formula weight ratio.

[0023] b. Mixing: keep the temperature of the front roll of the open mill at 55°C and the temperature of the rear roll at 50°C. Firstly, the plasticized natural rubber is wrapped on the front roll after passing through the roll gap of the open mill, and an appropriate amount of rubber is left above the roll gap. After 2 minutes of kneading to form a smooth and gap-free wrapping rubber, the rubber material is cut and removed; then the rubber material is put into the roller distance and pressed for 2 minutes, and zinc oxide, stearic acid, and anti-aging agent are sequentially added to the a...

Embodiment 2

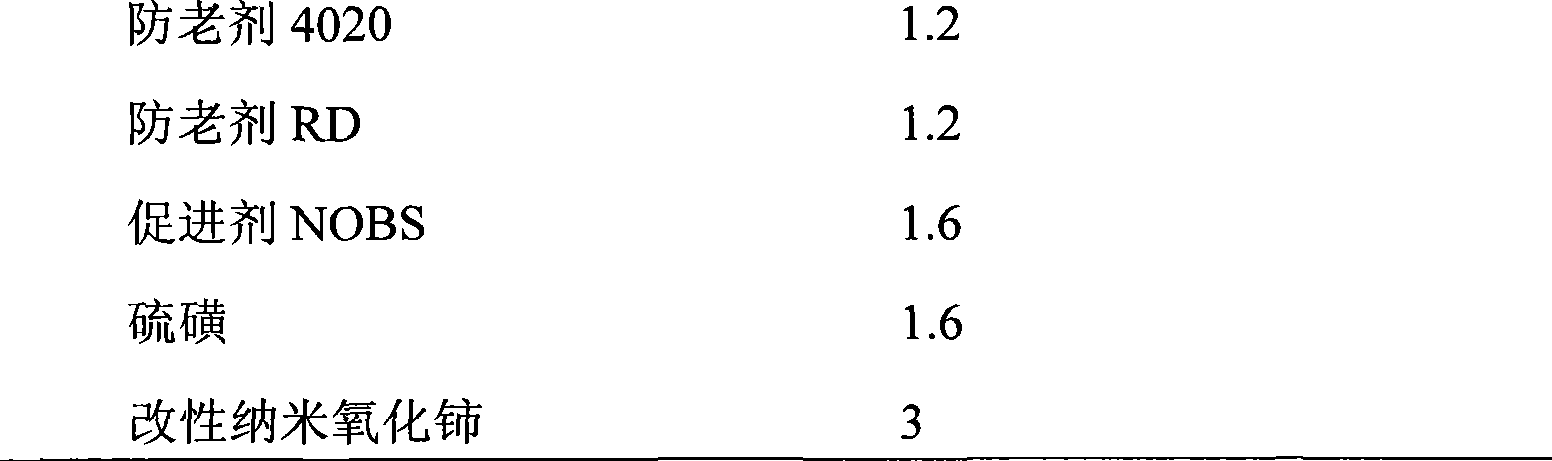

[0028] The high-performance engineered tire tread rubber formula based on nano powder of the present embodiment is:

[0029]

[0030] The preparation process of the high-performance engineering tire tread rubber based on nano-powder of the present embodiment is:

[0031] a. Ingredients: Weigh the required quality of various raw materials according to the formula weight ratio.

[0032] b. Mixing: keep the temperature of the front roll of the open mill at 55°C and the temperature of the rear roll at 50°C. Firstly, the plasticized natural rubber is wrapped on the front roll after passing through the roll gap of the open mill, and an appropriate amount of rubber is left above the roll gap. After 2 minutes of kneading to form a smooth and gap-free wrapping rubber, the rubber material is cut and removed; then the rubber material is put into the roller distance and pressed for 2 minutes, and zinc oxide, stearic acid, and anti-aging agent are sequentially added to the accumulated r...

Embodiment 3

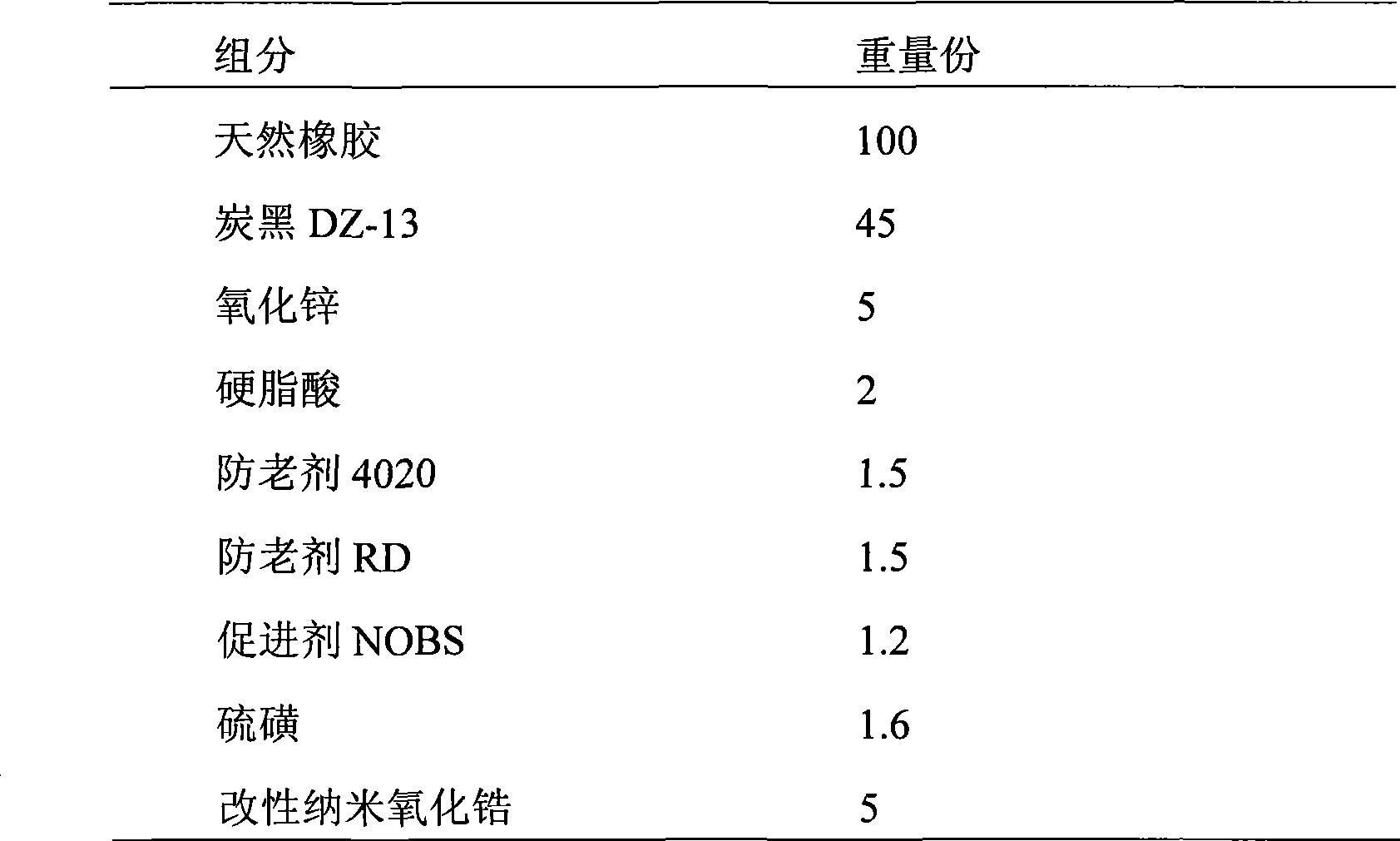

[0037] The high-performance engineered tire tread rubber formula based on nano powder of the present embodiment is:

[0038]

[0039] The preparation process of the high-performance engineering tire tread rubber based on nano-powder of the present embodiment is:

[0040] a. Ingredients: Weigh the required quality of various raw materials according to the formula weight ratio.

[0041] b. Mixing: keep the temperature of the front roll of the open mill at 55°C and the temperature of the rear roll at 50°C. Firstly, the plasticized natural rubber is wrapped on the front roll after passing through the roll gap of the open mill, and an appropriate amount of rubber is left above the roll gap. After 2 minutes of kneading to form a smooth and gap-free wrapping rubber, the rubber material is cut and removed; then the rubber material is put into the roller distance and pressed for 2 minutes, and zinc oxide, stearic acid, and anti-aging agent are sequentially added to the accumulated r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com