Special high-strength wear-resistant sealing ring of high pressure resistant self-sealing rotary compensator

A rotary compensator and self-sealing technology, applied in the direction of engine sealing, expansion compensation device for pipelines, pipes/pipe joints/pipe fittings, etc., can solve the problem that the annular sealing ring cannot be satisfied, and achieve simple structure and pressure resistance. Good performance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

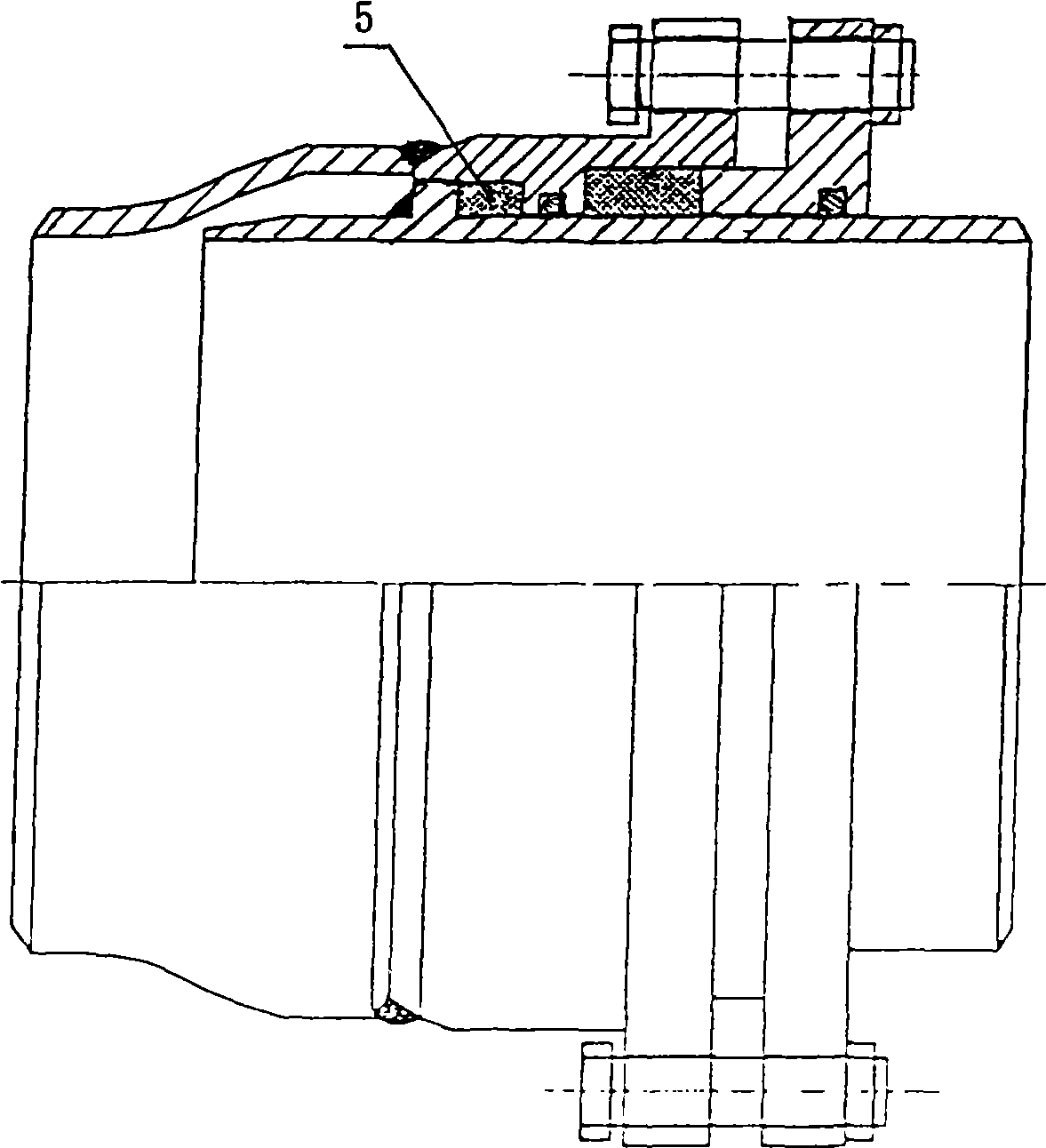

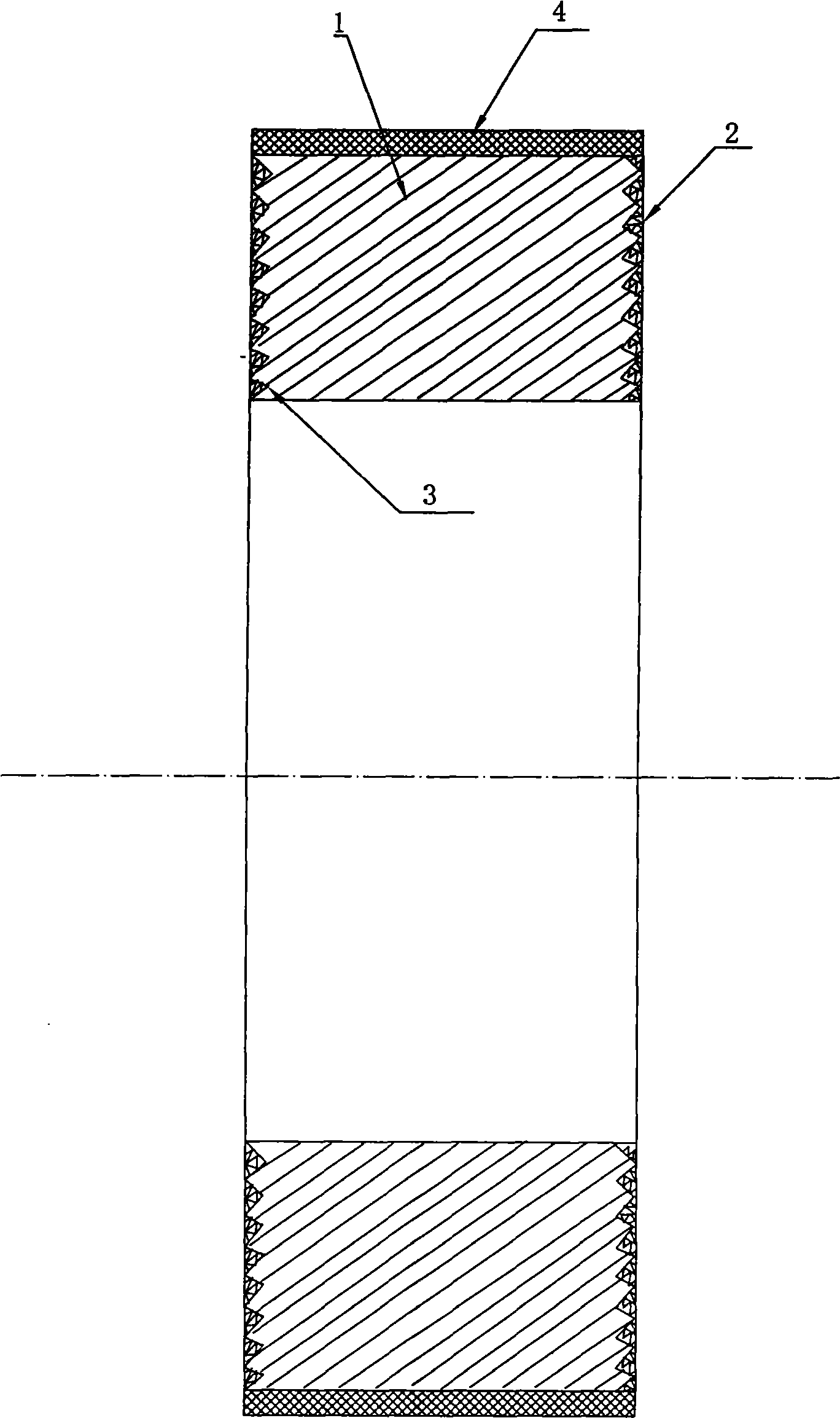

[0018] Such as figure 2 shown.

[0019] A special high-strength and wear-resistant sealing ring for high-pressure self-sealing rotary compensators, the applicable pressure range is between 50MPa and 200MPa, and it is mainly composed of an annular support body 1 and a graphite sealing layer 2, and the graphite sealing layer 2 is passed through a high-pressure It is fixed on the two end faces of the annular support body 1 (the annular support body 1 and the graphite sealing layer 2 can be placed in the mould, and then the mold is molded on a 500-ton press), and the size of the annular support body 1 is determined by The size of the rotary compensator is determined, and its thickness generally does not exceed 50 mm, while the thickness of the graphite sealing layer 2 is generally between 0.5 and 5 mm. In order to improve the bonding strength between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com