Pressure control valve for controlling opening degree of valve core through utilization of sensing element and refrigeration system

A technology of pressure control and spool control, applied in refrigerators, engine components, refrigeration and liquefaction, etc., can solve problems such as difficult quality assurance, leakage of bellows or welding areas, safety accidents, etc., to achieve mature manufacturing process and guarantee The effect of controlling the process and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

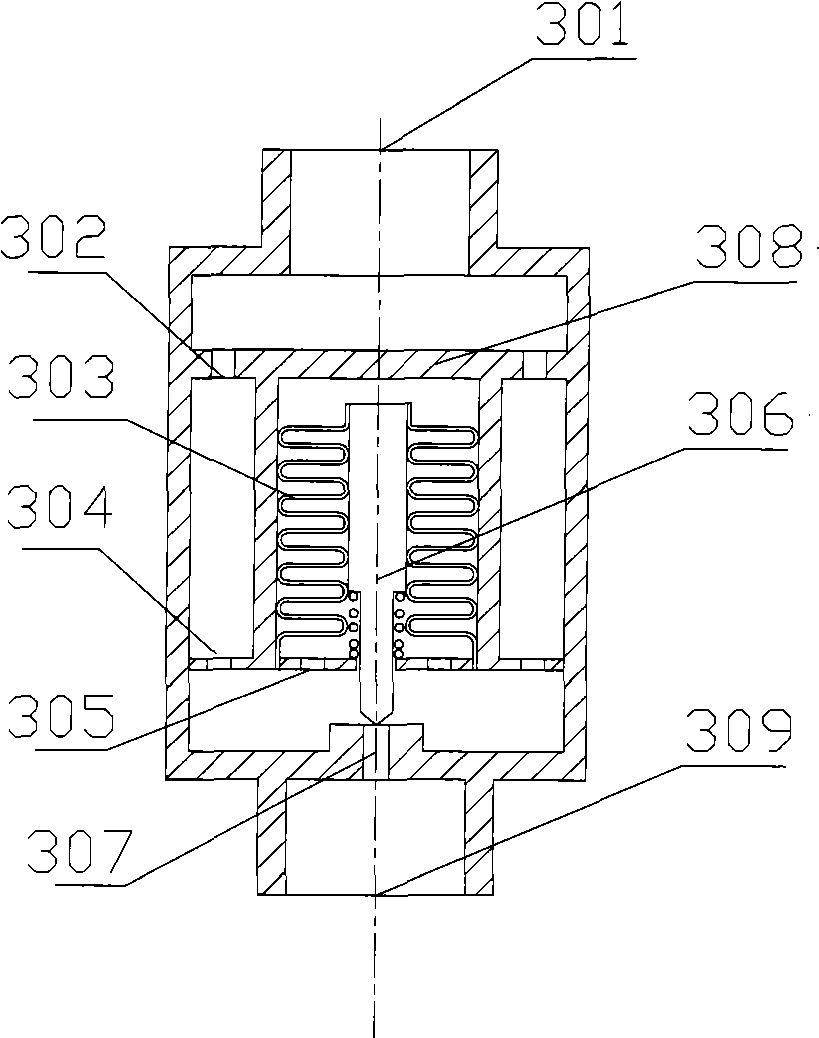

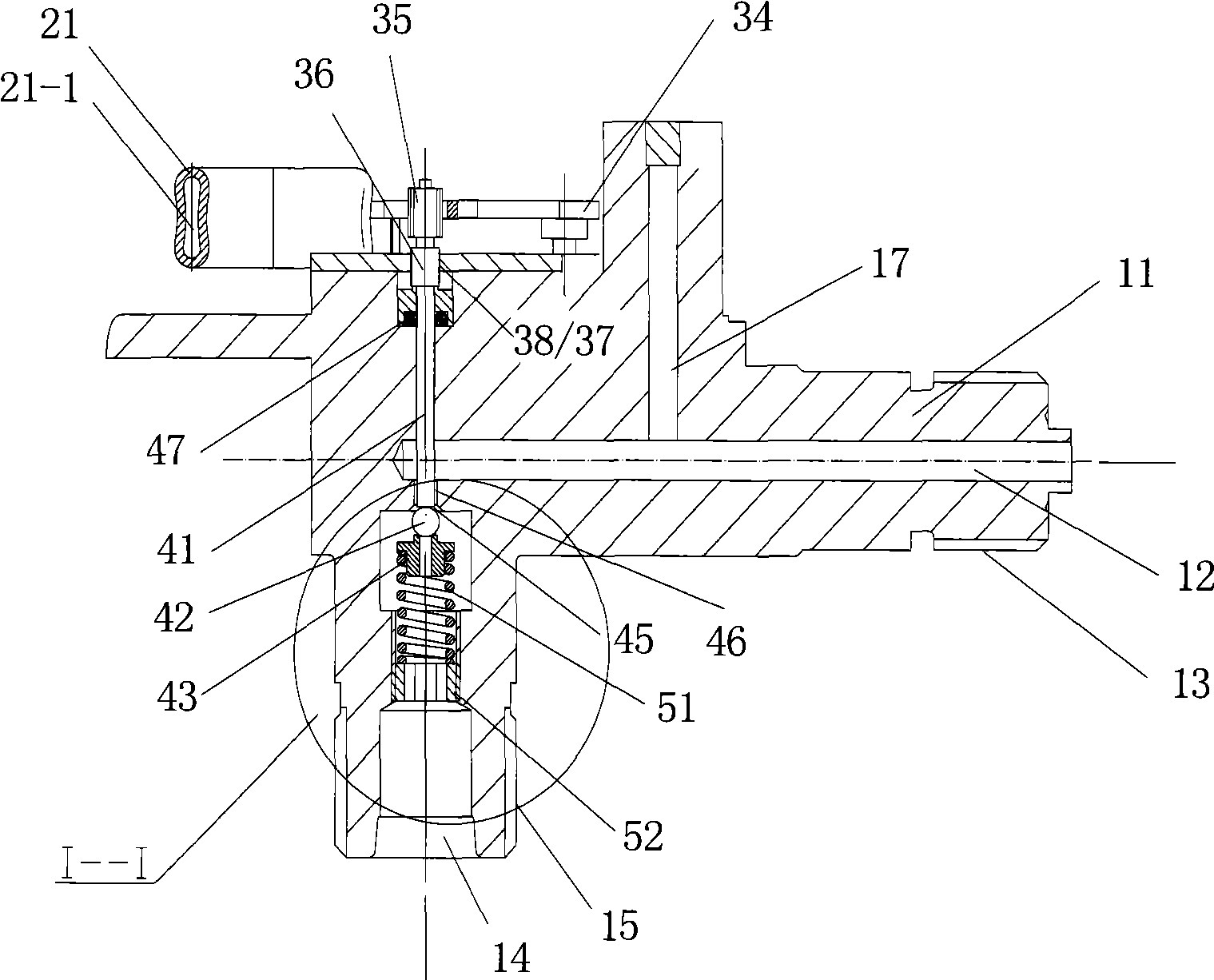

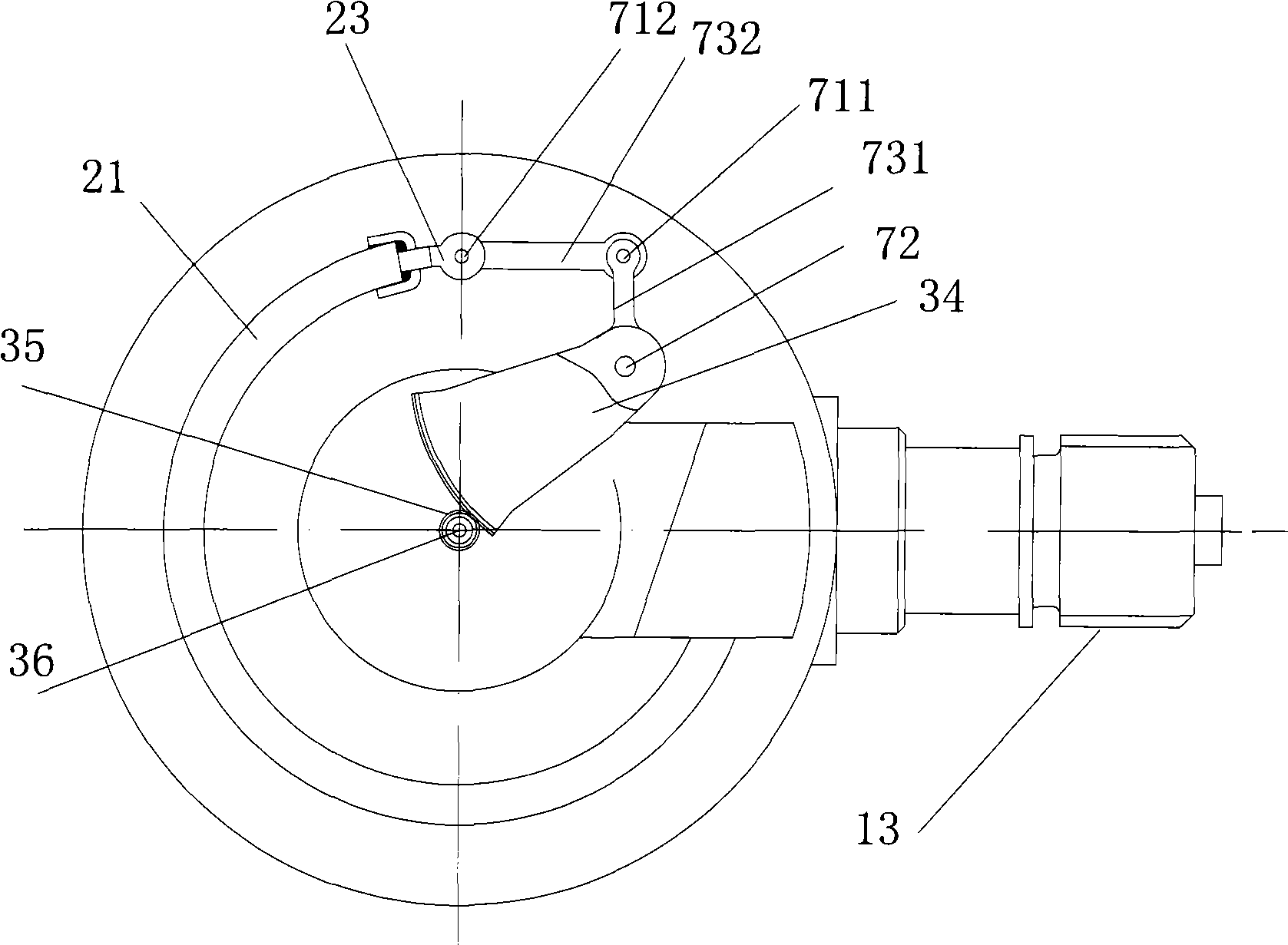

[0041] The basic idea of the present invention is to replace the bellows or elastic bellows in the prior art with a sensitive element such as a Bourdon tube as a pressure sensor, and by sensing the change in the pressure at the inlet end, the elastic deformation of the Bourdon tube will pass through the corresponding mechanism. It is converted into a change in the position of the spool, thereby realizing the control of the outlet pressure of the control valve. Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0042] Although the embodiments in this part are described in the background of controlling the pressure of the high-pressure refrigerant in the transcritical carbon dioxide refrigeration system, it does not limit the application in other similar occasions. figure 2 It is a schematic diagram of the internal structure of the pressure control valve in Embodiment 1, image 3 yes figure 2 Top v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com