Hot-cathode gas discharge long life lamp without filament

A gas discharge and hot cathode technology, applied in the field of electric light sources, can solve the problems of reduced photoelectric conversion efficiency and use safety, blackening at both ends of the lamp tube, large cathode drop, etc., and achieve glass light transmission and photoelectric conversion efficiency High, simple production process and equipment, less sputtering evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

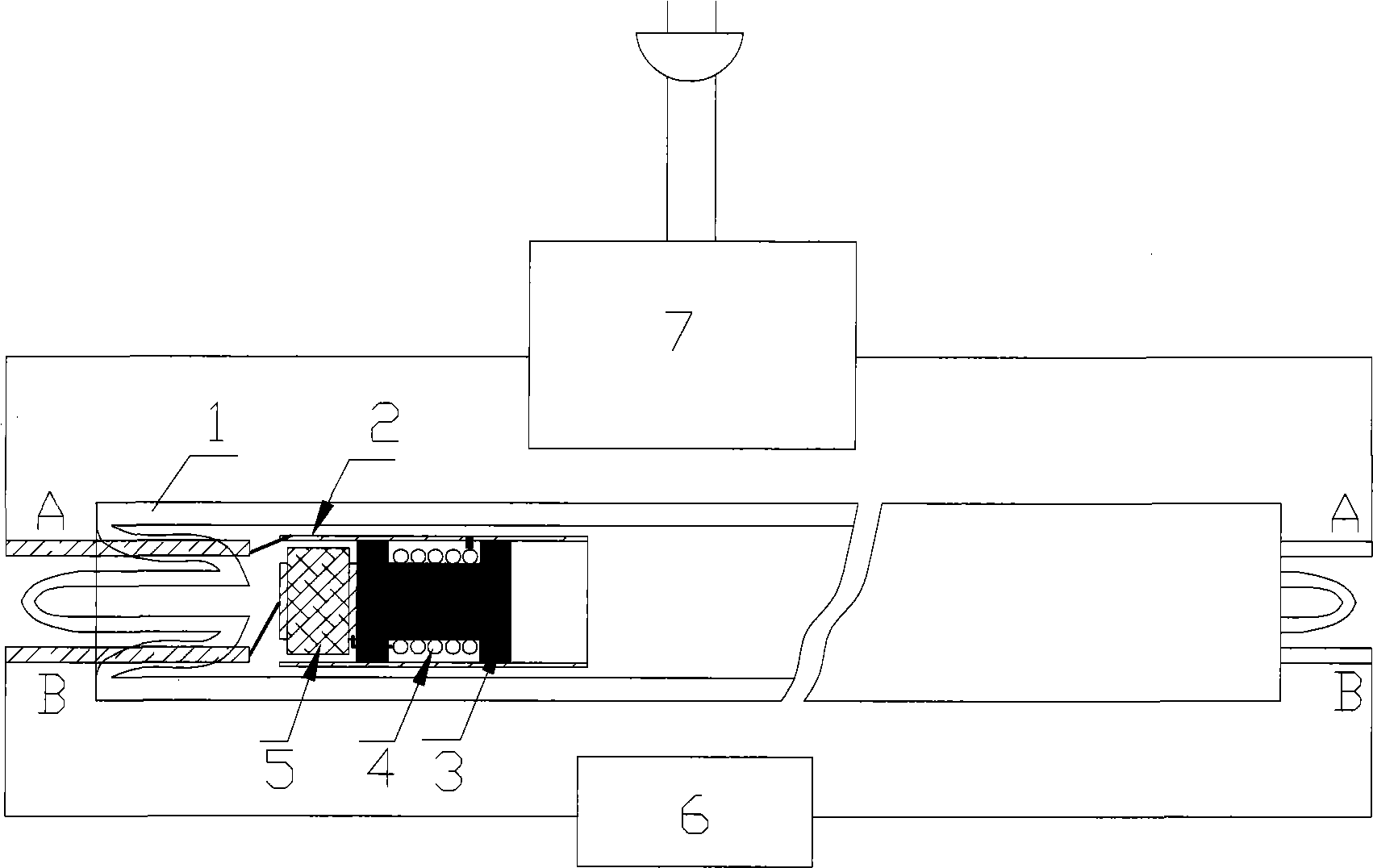

[0015] The present invention will be further described below in conjunction with the accompanying drawings and an embodiment of a hot cathode gas discharge long-life lamp without filament.

[0016] According to the method of the present invention, a thin-walled copper tube can be used to make a cylindrical main electrode 2 with an inner diameter of about 8 mm, a wall thickness of 0.2 mm, and a length of about 20 mm. , a ferrite core 3 with an I-shaped cross section, on which an induction coil 4 is wound. The magnetic core 3 divides the cylindrical electrode into two chambers. The inner wall of one end chamber is coated with high-efficiency thermionic emission material (electron powder), and the other end is filled with a circular pie-shaped CPTC ceramic heat sink with a diameter of about 7 mm and a thickness of 4 mm. Sensitive resistor 5. One of its surface electrodes is electrically connected to one end of the induction coil 4, and the other surface electrode is welded to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com