Flavor deterioration inhibitor and inhibitor for the generation of citral deterioration smell

A technology of citral and inhibitors, which is applied in the field of aroma deterioration inhibitors, and can solve problems such as no effective method found and product quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0169] [Example 1] (oral cleanser)

[0170] Mix according to the following formula to make oral cleanser.

[0171] Ethanol 15.0g

[0172] Glycerin 10.0g

[0173] Polyoxyethylene 2.0g

[0175] Sodium Benzoate 0.05g

[0176] Spice 0.3g

[0177] Sodium dihydrogen phosphate 0.1g

[0178] Colorant 0.2g

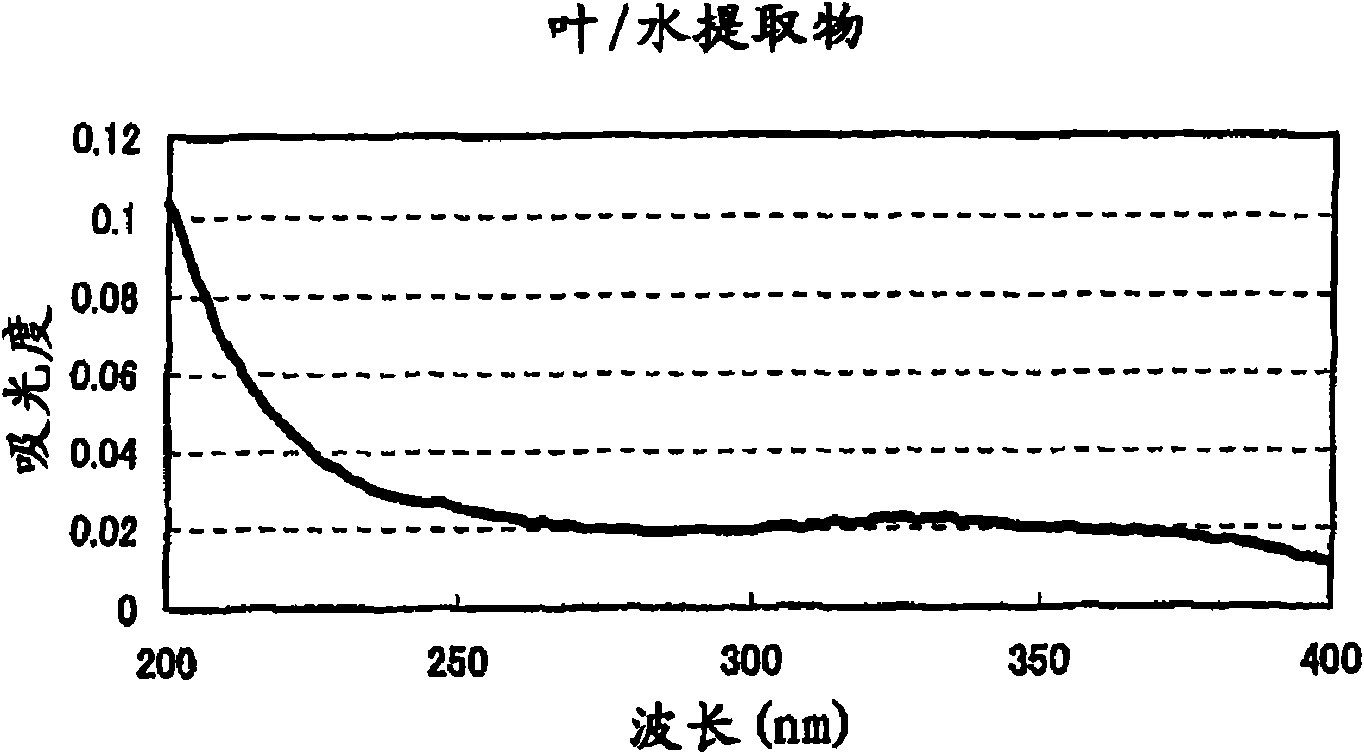

[0179] 1 wt% / 50 wt% aqueous ethanol solution of leaf / water extract 0.1g

[0180] Distilled water 72.1g

Embodiment 2

[0181] [Example 2] Margarine

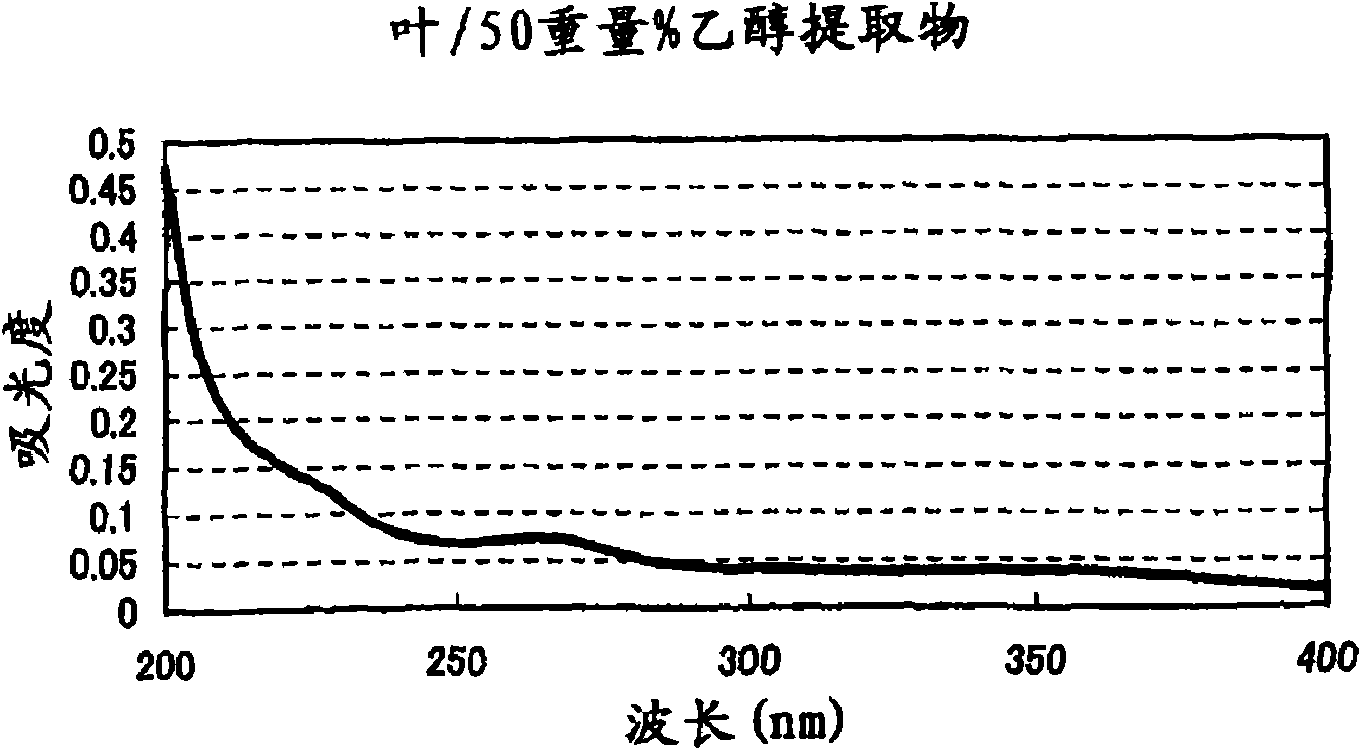

[0182] Mix 55g of shortening, 15g of corn oil, 0.1g of 30% β-carotene solution, 0.2g of lecithin, and 0.3g of emulsifier, and sterilize at 80°C for 10 minutes in a hot water bath. On the other hand, 27.9 g water, 0.5 g salt, 1 g skim milk powder, 0.1 g angelica leaf / 50 wt % ethanol extract 1 wt % / 50 wt % ethanol aqueous solution were mixed, and heated to 85° C. in a hot water bath. The obtained corn oil mixture and skim milk powder mixture were each cooled to 50 to 60° C., mixed, and stirred with a disperser at 1,500 rpm for 5 minutes while cooling with ice water. The whole was fully kneaded with a rubber spatula (gombera) while cooling with water (cooling to 10° C.). Remove to a container and let it mature overnight in the refrigerator to make the margarine.

Embodiment 3

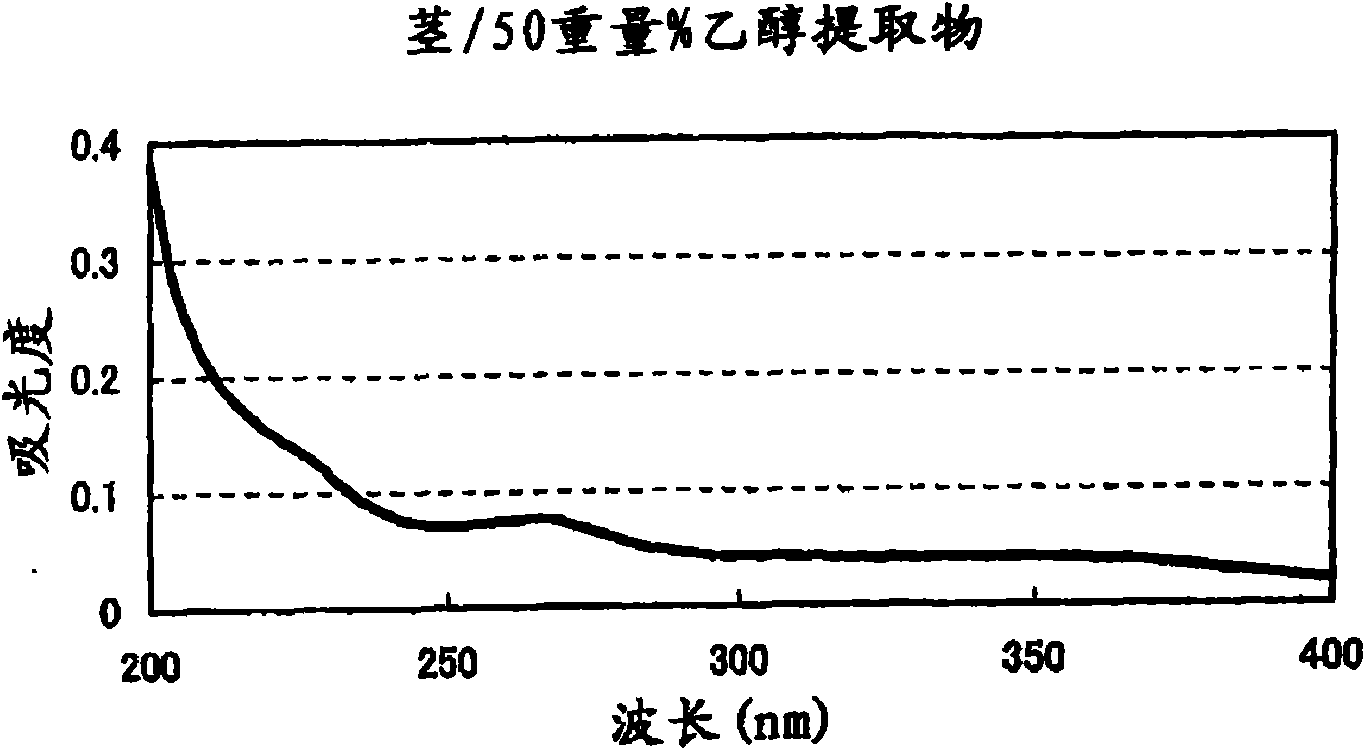

[0183] [Example 3] Vanilla extract

[0184] Add 35 g of ethanol and 65 g of distilled water to 10 g of vanilla beans, and stand in the dark at room temperature for extraction for 4 weeks. The solution was filtered to obtain 90 g of vanilla extract. To 90 g of this extract was added 10 g of a stem of 1% by weight of Angelica sinensis / 50% by weight of ethanol extract / 50% by weight of ethanol aqueous solution to prepare the vanilla extract of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com